Active no-tillage planter

A kind of seeder, active technology, applied in the direction of fertilizer and seeding equipment, planting methods, agricultural machinery and implements, etc., can solve the problem of not meeting the anti-blocking requirements of no-tillage operations, low degree of mechanization, and unsuitable for operations in hilly and mountainous areas Environmental issues, to achieve the effect of reducing human labor, less soil disturbance, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

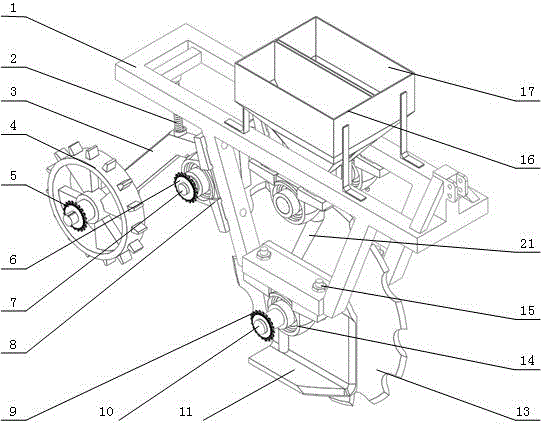

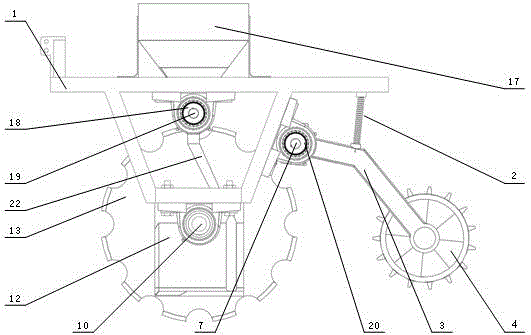

[0023] Embodiment 1: as Figure 1-2 As shown, an active no-tillage seeder includes a frame assembly, an anti-blocking ditching assembly, a fertilization and seeding assembly, a soil covering and suppression assembly and a transmission assembly, wherein the anti-blocking ditching assembly, the fertilization and seeding assembly Formation, overburden suppression assembly and transmission assembly are fixedly installed on the frame assembly;

[0024] The anti-blocking ditching assembly includes a driving sprocket 9, a driving shaft 10, an L-shaped ditching knife I11, an L-shaped ditching knife II12, and a disc stubble cutter 13; At one end, the disc stubble cutting knife 13 is installed on the drive shaft 10, and the L-shaped ditching knife I11 and the L-shaped ditching knife II12 are respectively arranged on both sides of the disc stubble cutting knife 13.

[0025] The frame assembly includes a frame 1 , a bearing 14 and a connecting bolt 15 ; wherein the bearing 14 is mounted ...

Embodiment 2

[0029] Embodiment 2: as Figure 1-2 As shown, an active no-tillage seeder includes a frame assembly, an anti-blocking ditching assembly, a fertilization and seeding assembly, a soil covering and suppression assembly and a transmission assembly, wherein the anti-blocking ditching assembly, the fertilization and seeding assembly Formation, overburden suppression assembly and transmission assembly are fixedly installed on the frame assembly;

[0030] The anti-blocking ditching assembly includes a driving sprocket 9, a driving shaft 10, an L-shaped ditching knife I11, an L-shaped ditching knife II12, and a disc stubble cutter 13; At one end, the disc stubble cutting knife 13 is installed on the drive shaft 10, and the L-shaped ditching knife I11 and the L-shaped ditching knife II12 are respectively arranged on both sides of the disc stubble cutting knife 13.

[0031] The frame assembly includes a frame 1 , a bearing 14 and a connecting bolt 15 ; wherein the bearing 14 is mounted ...

Embodiment 3

[0032] Embodiment 3: as Figure 1-2 As shown, an active no-tillage seeder includes a frame assembly, an anti-blocking ditching assembly, a fertilization and seeding assembly, a soil covering and suppression assembly and a transmission assembly, wherein the anti-blocking ditching assembly, the fertilization and seeding assembly Formation, overburden suppression assembly and transmission assembly are fixedly installed on the frame assembly;

[0033] The anti-blocking ditching assembly includes a driving sprocket 9, a driving shaft 10, an L-shaped ditching knife I11, an L-shaped ditching knife II12, and a disc stubble cutter 13; At one end, the disc stubble cutting knife 13 is installed on the drive shaft 10, and the L-shaped ditching knife I11 and the L-shaped ditching knife II12 are respectively arranged on both sides of the disc stubble cutting knife 13.

[0034] The fertilization and seeding assembly includes a seed box 16, a fertilizer box 17, a seed sprocket 18, a seed sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com