Jacking conveying type fermentation engineering solid-liquid separation device

A technology for fermentation engineering and solid-liquid separation, applied in the field of fermentation engineering, can solve the problems of complex separation devices, waste, and increased costs, and achieve the effects of improving separation efficiency, ensuring solid-liquid separation, and reducing human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

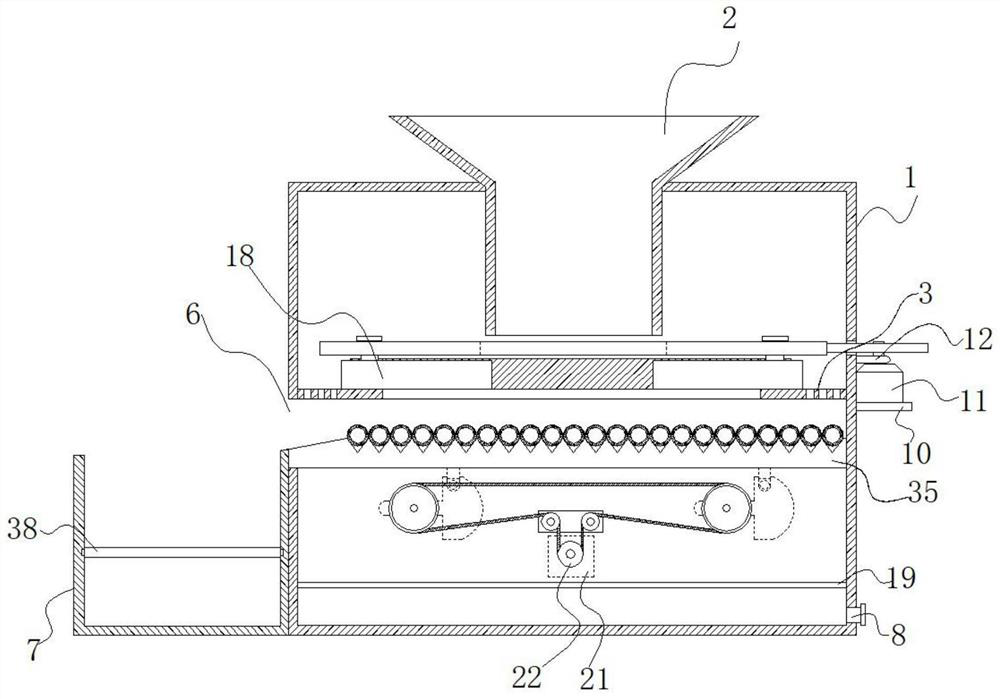

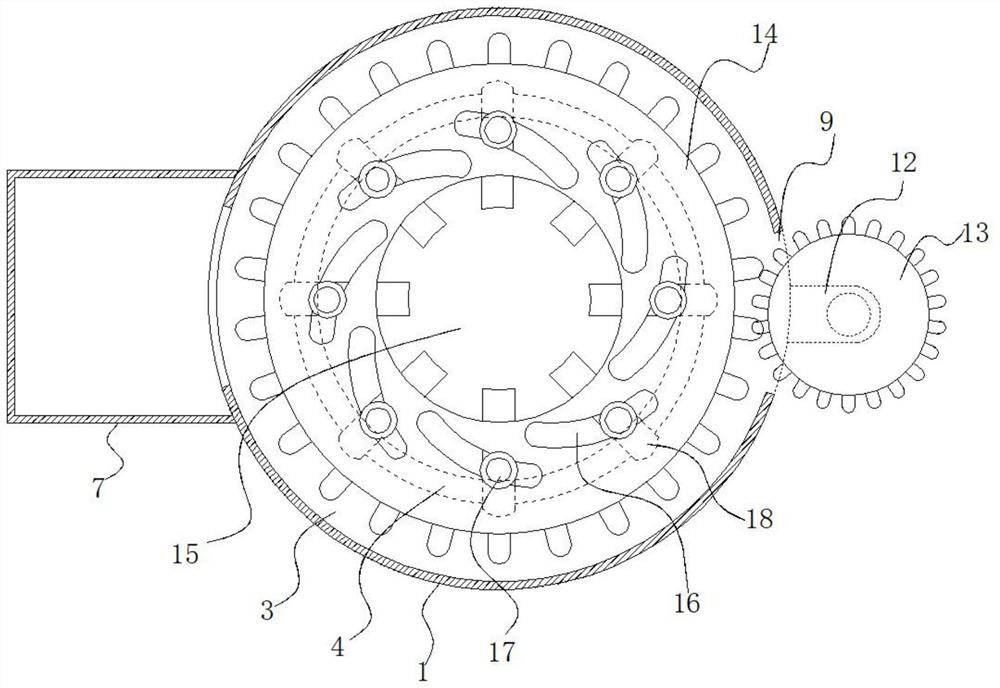

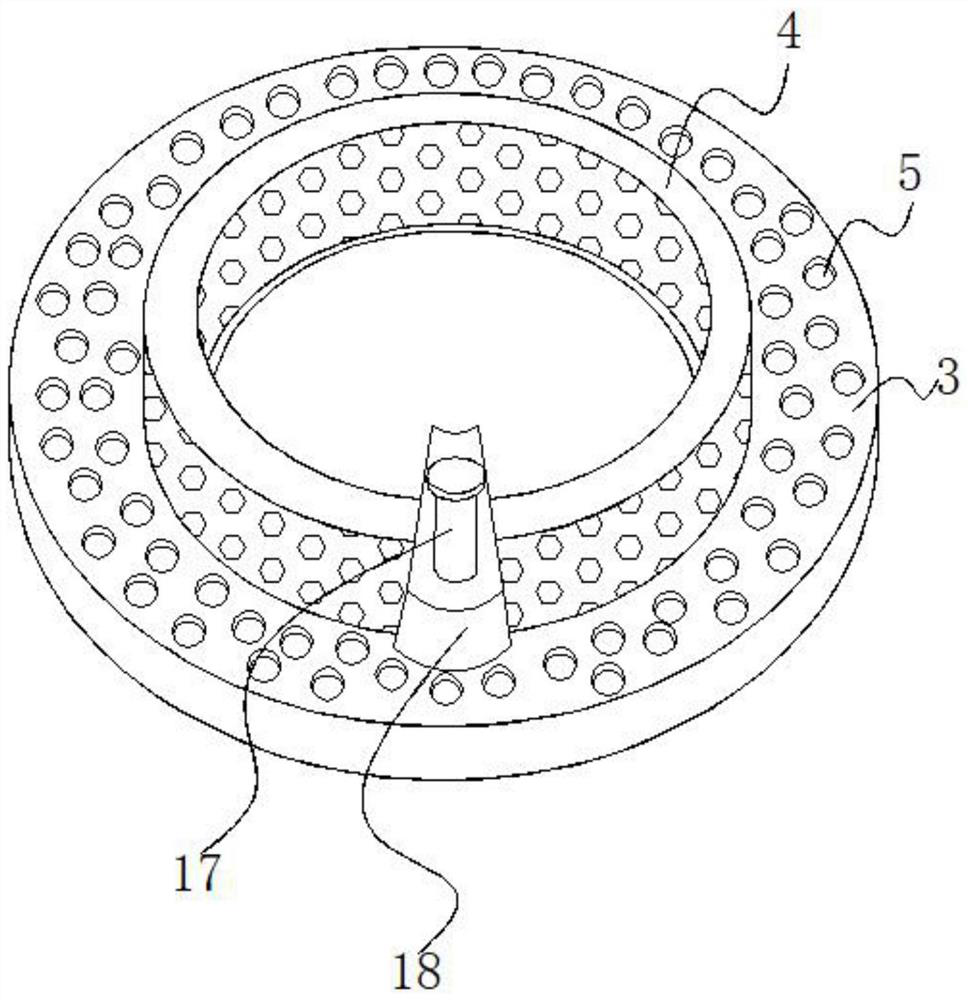

[0033] Such as Figure 1-3 displayed in:

[0034] The invention provides a jacking conveying type solid-liquid separation device for fermentation engineering, which includes a box body 1, a feeding funnel 2 is arranged at the center of the top of the box body 1, and a squeezer is arranged below the feeding funnel 2. device, the bottom of the extruding device is provided with a support platform 3, the top center of the support platform 3 is provided with a boss 4, the middle part of the boss 4 and the middle part of the support platform 3 are provided with a channel, A discharge valve is installed on the channel set in the middle of the support platform 3, and several water outlet holes 5 are provided on the top periphery of the support platform 3 and the side of the boss 4, and the bottom of the support platform 3 One side is provided with a discharge port 6 at the middle part of the side of the box body 1, and a solid collection box 7 is provided on the side of the box body ...

Embodiment 2

[0037] Such as figure 1 , Figure 4-7 displayed in:

[0038] The invention provides a jacking conveying type solid-liquid separation device for fermentation engineering, which includes a box body 1, a feeding funnel 2 is arranged at the center of the top of the box body 1, and a squeezer is arranged below the feeding funnel 2. device, the bottom of the extruding device is provided with a support platform 3, the top center of the support platform 3 is provided with a boss 4, the middle part of the boss 4 and the middle part of the support platform 3 are provided with a channel, A discharge valve is installed on the channel set in the middle of the support platform 3, and several water outlet holes 5 are provided on the top periphery of the support platform 3 and the side of the boss 4, and the bottom of the support platform 3 One side is provided with a discharge port 6 at the middle part of the side of the box body 1, and a solid collection box 7 is provided on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com