A button battery automatic butt welding device

A button battery, automatic technology, applied in auxiliary devices, resistance welding equipment, welding equipment and other directions, can solve the problems of difficult to achieve assembly line production, unsatisfactory workpiece fixation control, low degree of automation, etc., saving labor and simple structure. , to facilitate the effect of before and after activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

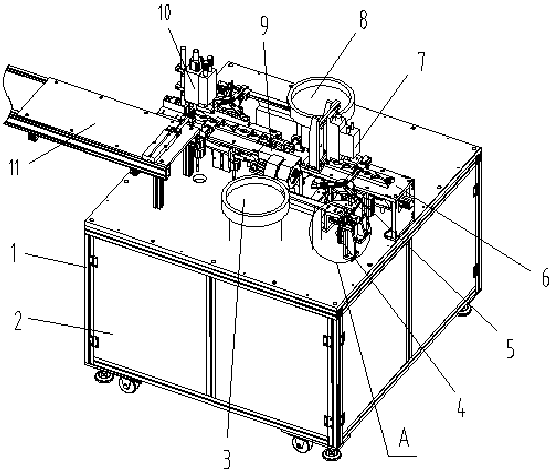

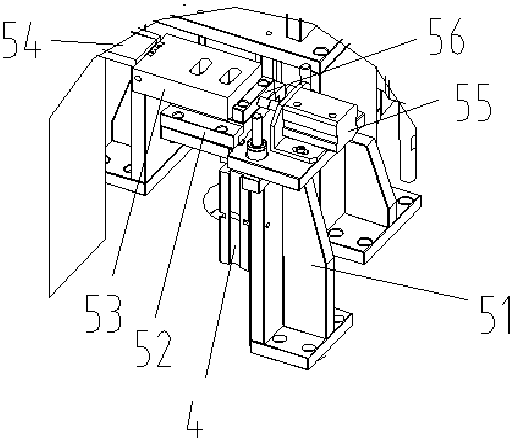

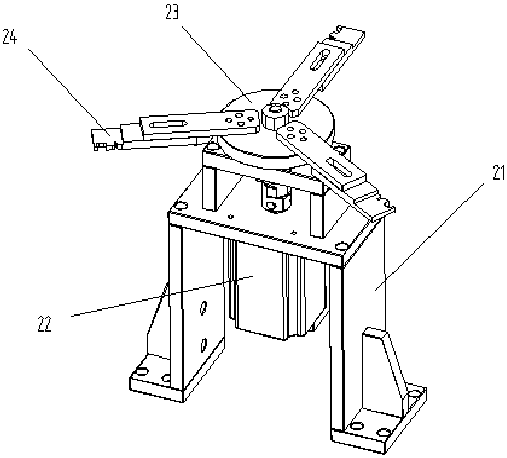

[0034] like Figure 1-Figure 6As shown, the specific structure of the present invention is: a button battery automatic butt welding device, which includes a frame 1, a power distribution control box 2 is arranged on the described frame 1, and a power distribution control box 2 is set on the described power distribution control box 2 There are two groups of feeding devices 6, and the feeding devices 6 are respectively provided with a negative electrode butt welding machine 7 and a positive electrode butt welding machine 10, and the two groups of feeding devices 6 are equipped with a negative electrode feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com