Metal window welding clamp device

A fixture device and welder technology, applied in metal processing equipment, auxiliary devices, manufacturing tools, etc., can solve problems such as poor welding quality, and achieve the effect of increasing the contact area of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

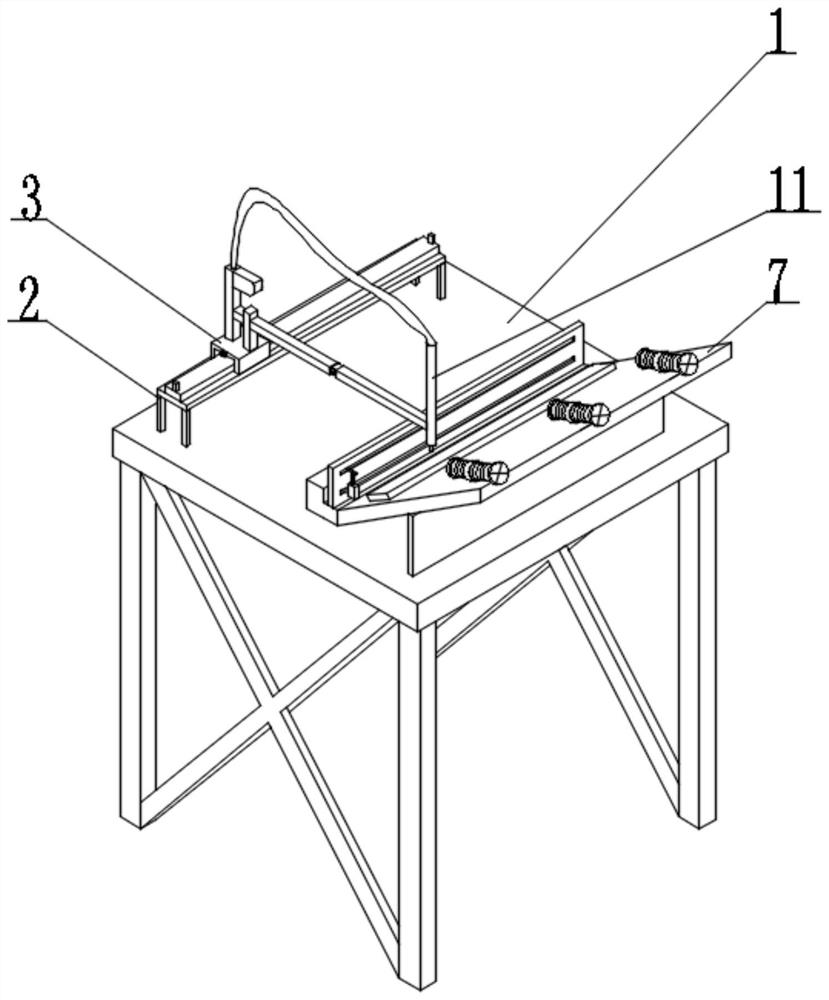

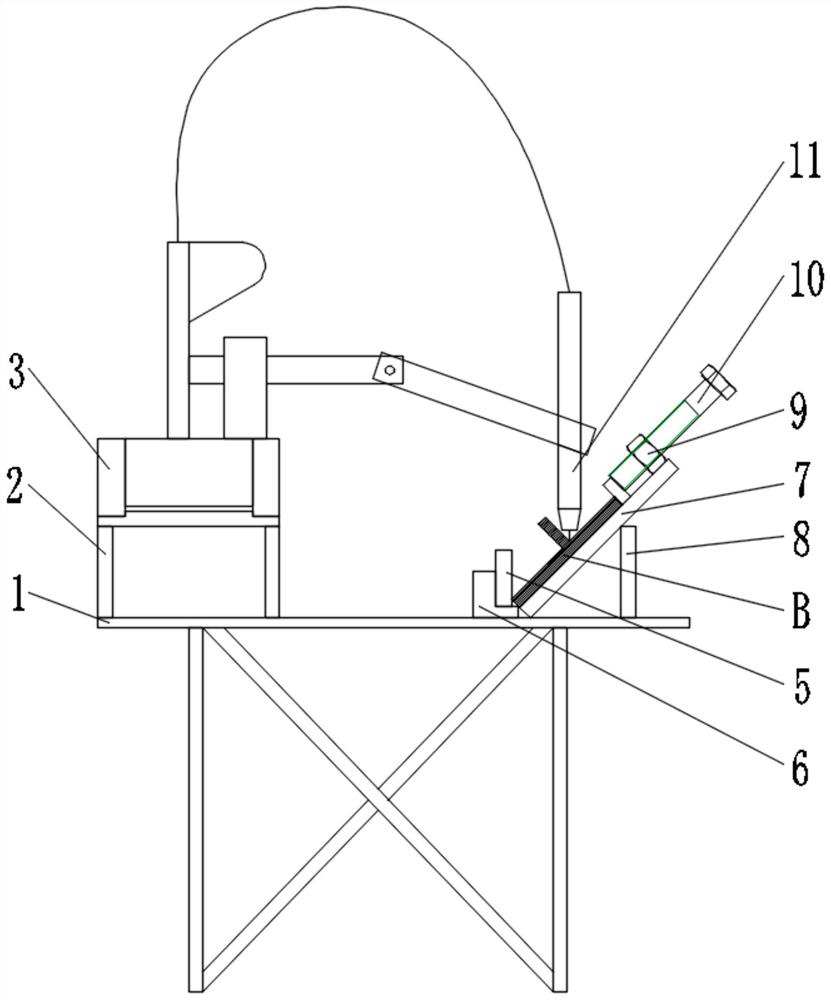

[0024] Example 1: See figure 1 and figure 2 , metal window welder fixture device, including welding base 1, welding trolley 3, welding positioning frame and pressing assembly, it is characterized in that: welding positioning frame is welded on welding base 1, and welding positioning frame includes a supporting base 7 that is arranged obliquely, The front end of the support seat 7 is fixed with the front positioning block 5, and the rear end of the support seat 7 is fixed to press the assembly; the window seat B for welding is placed on the support seat 7, the front end of the window seat B contacts the front positioning block 5, and the rear end of the window seat B The end is compressed by the pressing assembly; the walking guide rail 2 is fixed on the welding base 1, and the traveling guide rail 2 is arranged in parallel with the support seat 7, and the welding trolley 3 is slidably connected to the traveling guide rail 2, and the front end of the welding trolley 3 is conne...

Embodiment 2

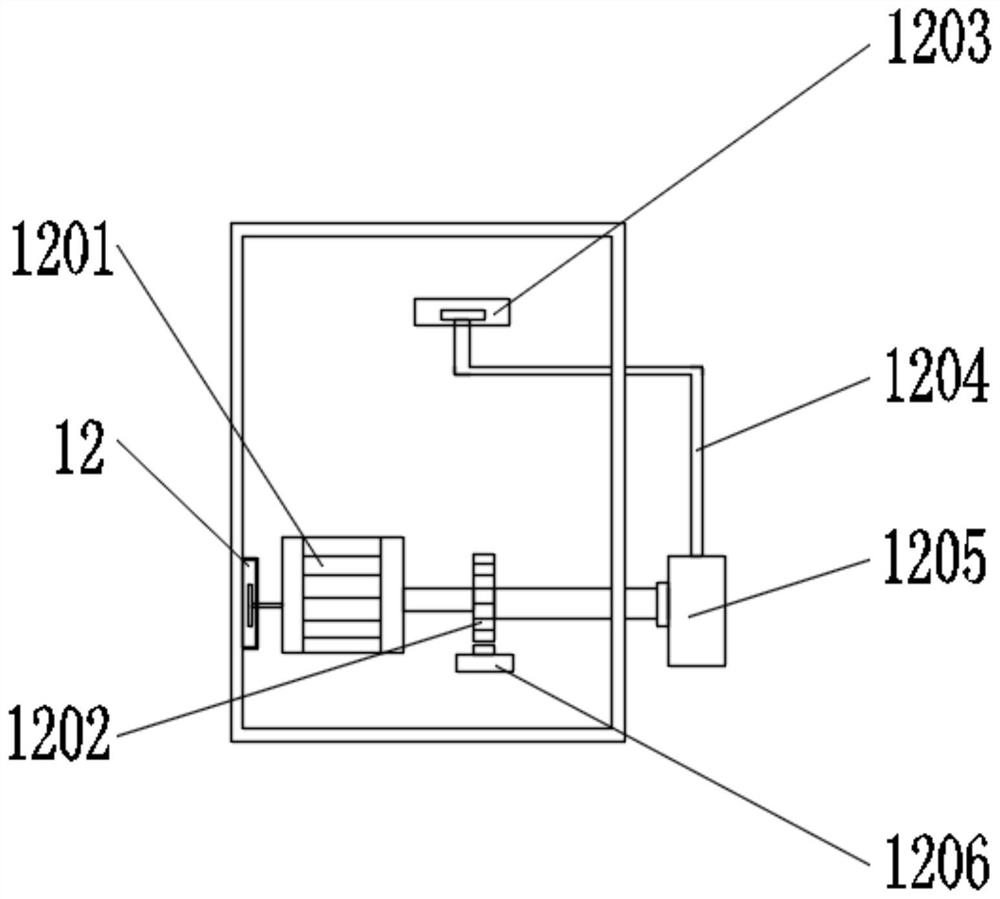

[0025] Example 2: see image 3 and Figure 4 , the inner wall of the first slideway 12 is equipped with a first pulley, one end of the first pulley is installed with a first pillar, one end of the first pillar is installed with a first motor 1201, and the output end of the first motor 1201 is installed with a rotating rod. The outer wall of the bar is equipped with a first gear 1202, and one end of the rotating bar is equipped with a push block 1205 through a bearing. The top of 1205 is equipped with bracket 1204, and one end of bracket 1204 is equipped with second pulley, and the outer wall of second pulley is connected with the inner wall of second slideway 1203, and the bottom of welding trolley 3 is equipped with second pole 1302, and the second support One end of the bar 1302 is equipped with a second motor 1303, and the output end of the second motor 1303 is equipped with a second gear 1301, and the second gear 1301 is engaged with the second gear rod 13, and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com