A non-metallic insert slotted nut

A slotted nut, non-metallic technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of the nut body coming out, the nut body loosening, etc., to increase the flanging length, reduce the probability of rotation, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

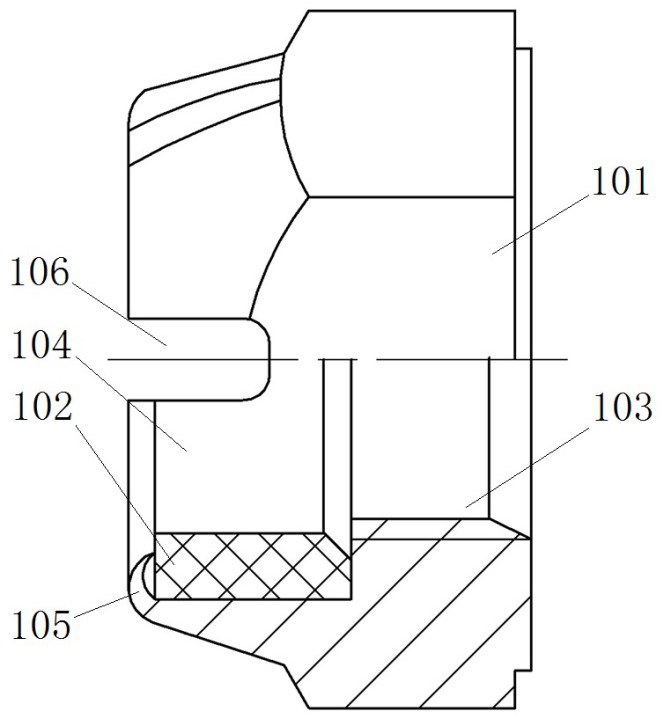

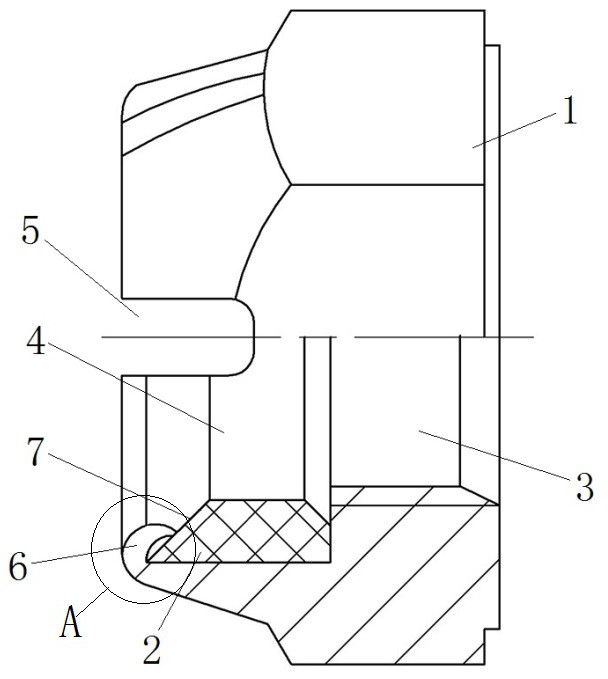

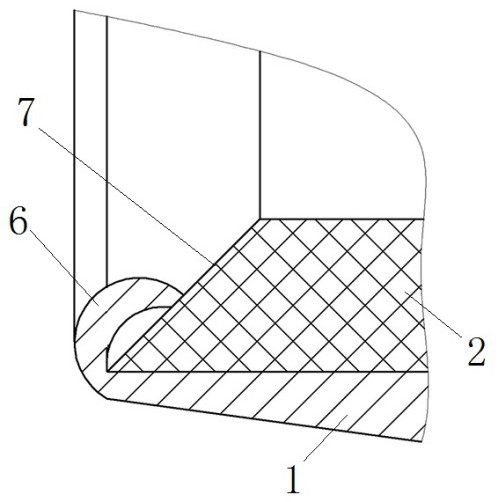

[0030] like figure 2 , The present invention is non-metallic insert slot nuts (hereinafter referred to as a nut) comprises a nut body and a non-metallic nut body fitted in an insert 2, 3 is provided with a threaded hole and a counter bore on the nut body 4, 3 and threaded holes 4 through a coaxial counterbore, in the axial direction of the nut body 1, a nut threaded hole is provided outside the main body side of the six flat circumferential surface, for mating with an impact wrench, nut counterbore-side outer peripheral surface of the present the tapered outer circumferential surface is, near the cell wall thickness and counterbore at the aperture position near the cell wall thickness is less than 4 at the bottom position of the hole.

[0031] In this embodiment, the stop nut groove 5 is provided at the counterbore end of the nut, and spaced circumferentially evenly arranged, in order to lock a stopper pin fitted on the bolt to achieve a nut with a mating bolt during assembly asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com