Photocuring coating machine production line

A coating machine and production line technology, applied in the field of coating machines, can solve the problems of inability to adjust size and position, affecting product yield, and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

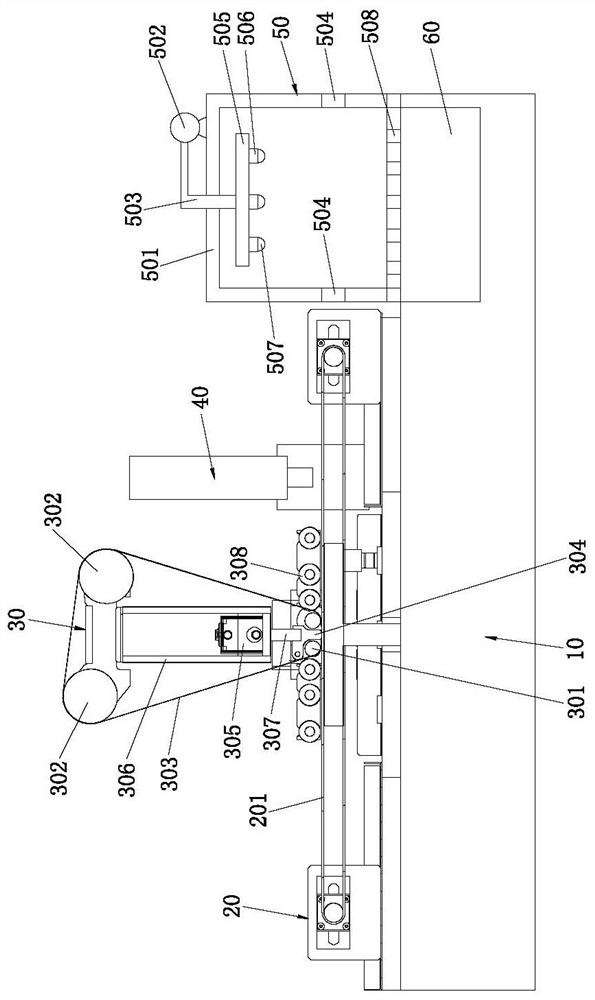

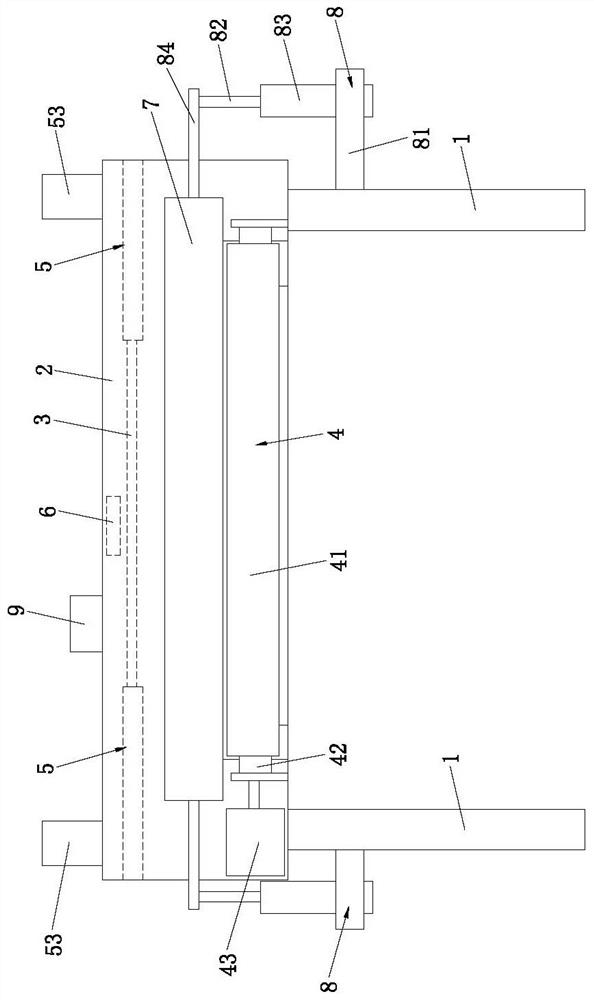

[0053] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the embodiment of the present invention.

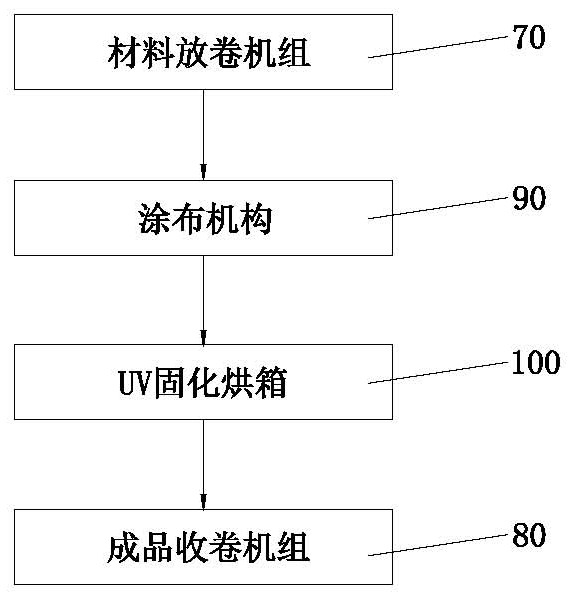

[0054] A light-curing coating machine production line, which includes a material unwinding unit 70, a coating mechanism 90, a UV curing oven 100, and a finished product rewinding unit 80 in sequence according to the process sequence; the material unwinding unit 70 includes a double-station unwinding unit Machine and material storage mechanism, the double-station unwinding machine and material storage mechanism are arranged on one side of the coating mechanism 90 in sequence from front to back.

[0055] Wherein, the coating mechanism 90 includes a machine platform 10 and a conveying device 20, a pressing device 30, a gluing device 40, and a drying device 50 arranged on the machine platform 10; the conveying device 20 includes a first conveyor belt 201 and a The first driving unit that drives the first conveyor belt 201 to move horizontally; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com