A high-intensity laser welding method and device for dissimilar metal assemblies

A dissimilar metal and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of narrow weld seam, large penetration depth, high welding clamping precision, etc., to achieve good forming and deep penetration Effect of large size and improved dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

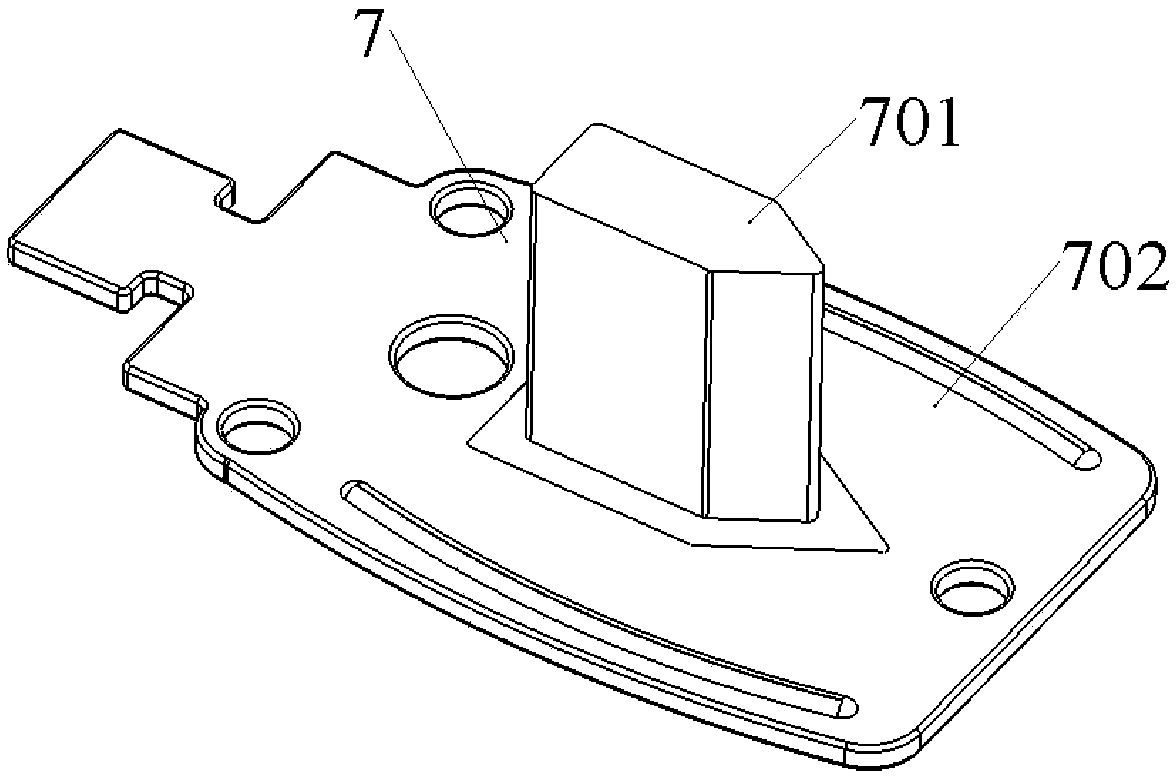

[0059] Such as figure 1 As shown, the dissimilar metal assembly 7 of the present invention is composed of an A metal column 701 and a B metal base 702, and the A metal column 701 and the B metal base 702, and the dissimilar metal assembly 7 formed after the two are assembled and welded are all Axisymmetric structure, the A metal column 701 is a prism structure, the cross section is a polygon, and the material is A metal, for example, it can be a copper column. The material of the B metal base is B metal, which is different from the material of the A metal column 701, for example, it may be a brass base. The surface of the B metal base 702 is provided with a profiling hole for assembling with the A metal column 701, and also provided with three positioning through holes. One end of the metal post 701 of A is inserted into the profili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com