Method for rectifying trichlorosilane

A technology of trichlorosilane and trichlorosilane, which is applied in the directions of halogenated silanes and halogenated silicon compounds, etc., achieves the effects of low cost, reduced mist entrainment and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

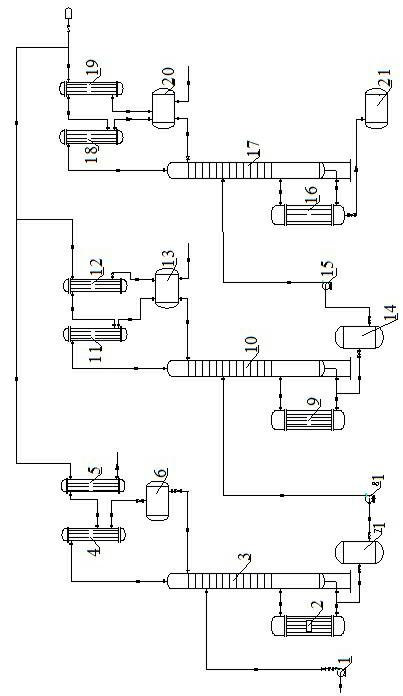

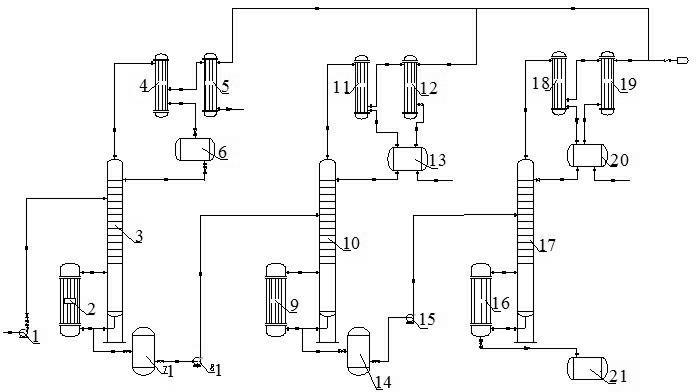

[0022] as attached figure 1 As shown, the crude synthetic liquid with a trichlorosilane concentration of about 85% sent from the synthesis section is driven into the upper feed port of the pre-tower 3 by the pre-tower feed pump 1, and the pre-tower is a guided sieve plate tower. The number of trays is 22~26, the pressure at the top of the tower is 60~70KPa, the temperature at the top of the tower is 40~50°C, and the reflux ratio is 0.1~0.3. The reboiler 2 at the lower part of the pre-column uses a jacket to feed 500Kpa saturated steam to indirectly heat the liquid crude trichlorosilane. There are two-stage condensers at the top of the pre-column. The chilled water is 400~500 Kpa, and the tube side of the secondary condenser is fed with frozen brine with a temperature of -25~-30°C and a pressure of 400~500 Kpa. The liquid condensed from the primary condenser 4 enters the reflux tank 6 of the pre-column, and the liquid enters the tower as reflux liquid by utilizing the potentia...

Embodiment 2

[0027] as attached figure 1 As shown, the crude synthetic liquid with a trichlorosilane concentration of about 85% sent from the synthesis section is driven into the upper feed port of the pre-tower 3 by the pre-tower feed pump 1, and the pre-tower is a guided sieve plate tower. The number of trays is 22, the pressure at the top of the tower is 60KPa, the temperature at the top of the tower is 50°C, and the reflux ratio is 0.3. The reboiler 2 at the lower part of the pre-column uses 500Kpa saturated steam to indirectly heat the liquid crude trichlorosilane, and there are two-stage condensers on the top of the pre-column, and the tube side of the first-stage condenser is fed with chilled water at a temperature of 5°C and a pressure of 400 Kpa , the tube side of the secondary condenser is fed with frozen brine with a temperature of -25°C and a pressure of 500 Kpa. The liquid condensed from the primary condenser 4 enters the pre-column reflux tank 6, and the liquid enters the to...

Embodiment 3

[0032] as attached figure 1 As shown, the crude synthetic liquid with a trichlorosilane concentration of about 85% sent from the synthesis section is driven into the upper feed port of the pre-tower 3 by the pre-tower feed pump 1, and the pre-tower is a guided sieve plate tower. The number of trays is 24, the pressure at the top of the tower is 65KPa, the temperature at the top of the tower is 45°C, and the reflux ratio is 0.2. The reboiler 2 at the lower part of the pre-column uses 500Kpa saturated steam to indirectly heat the liquid crude trichlorosilane, and there are two-stage condensers on the top of the pre-column, and the tube side of the first-stage condenser is fed with chilled water at a temperature of 6°C and a pressure of 450 Kpa , the tube side of the secondary condenser is fed with frozen brine with a temperature of -30°C and a pressure of 450 Kpa. The liquid condensed from the primary condenser 4 enters the reflux tank 6 of the pre-column, and the liquid enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com