Bidirectional water flow channel

A flow channel and water flow technology, applied in the field of two-way water flow channels, can solve the problems of difficult control of manufacturing precision, easy aging of elastic diaphragms, and affecting service life, etc., and achieve strong anti-blocking, low production cost, and not easy to aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

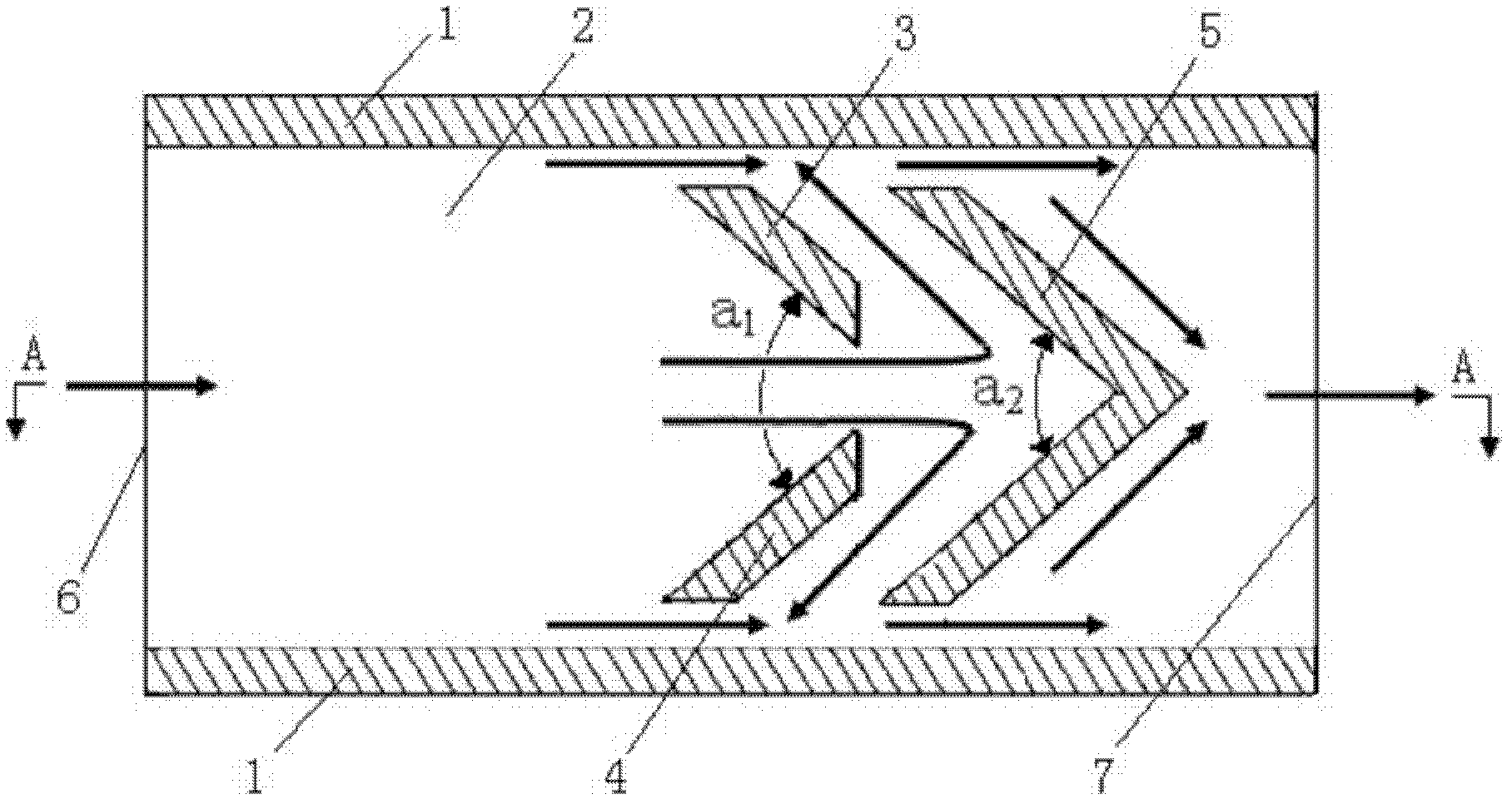

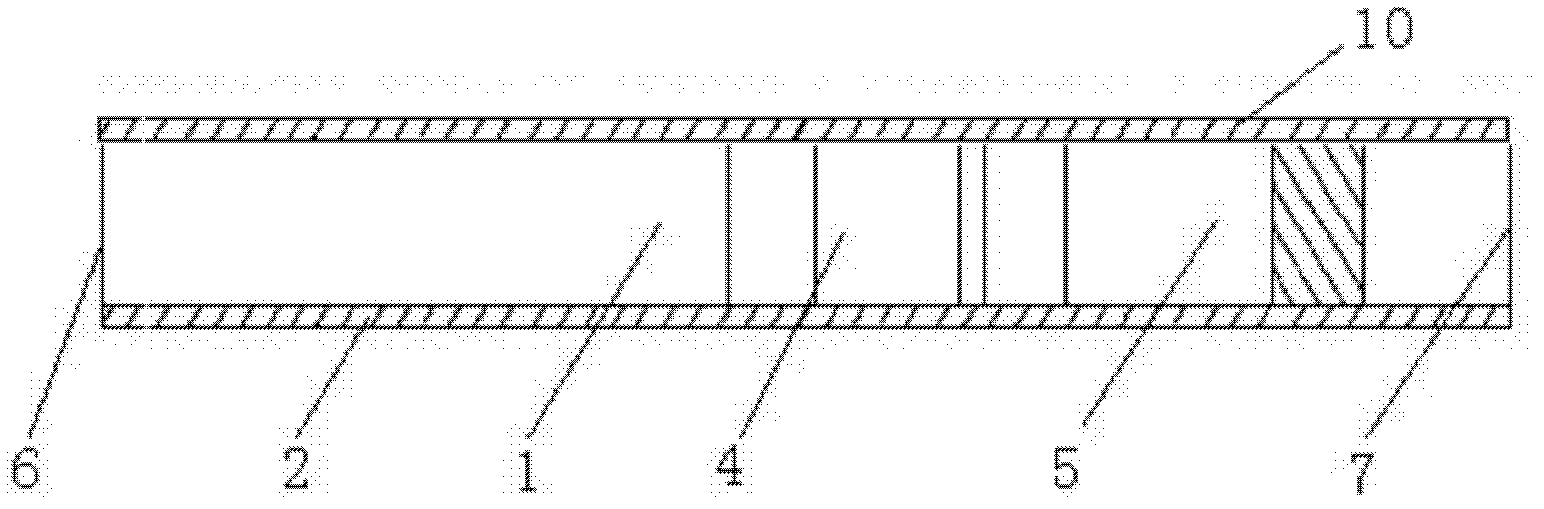

[0020] like figure 1 and figure 2 As shown, the two-way water flow channel of the present invention includes a rectangular bottom plate 2 , the front end of the bottom plate 2 is opened and serves as a water inlet 6 , and the rear end of the bottom plate 2 is opened and used as a water outlet 7 . The left and right sides of the bottom plate 2 are both symmetrical and parallel with a water-retaining outer wall 1 . On the bottom plate 2 and between the two water-retaining outer walls 1 , a first water diversion plate 3 , a second water diversion plate 4 and a water retaining member 5 are arranged. Wherein, the first water diversion plate 3 and the second water diversion plate 4 are spaced apart and symmetrically arranged left and right, and form a figure-eight water diversion piece. The gap between the first water diversion plate 3 and the second water diversion plate 4 is used as the water passing hole of the water diversion member. The water retaining member 5 is V-shaped ...

Embodiment 2

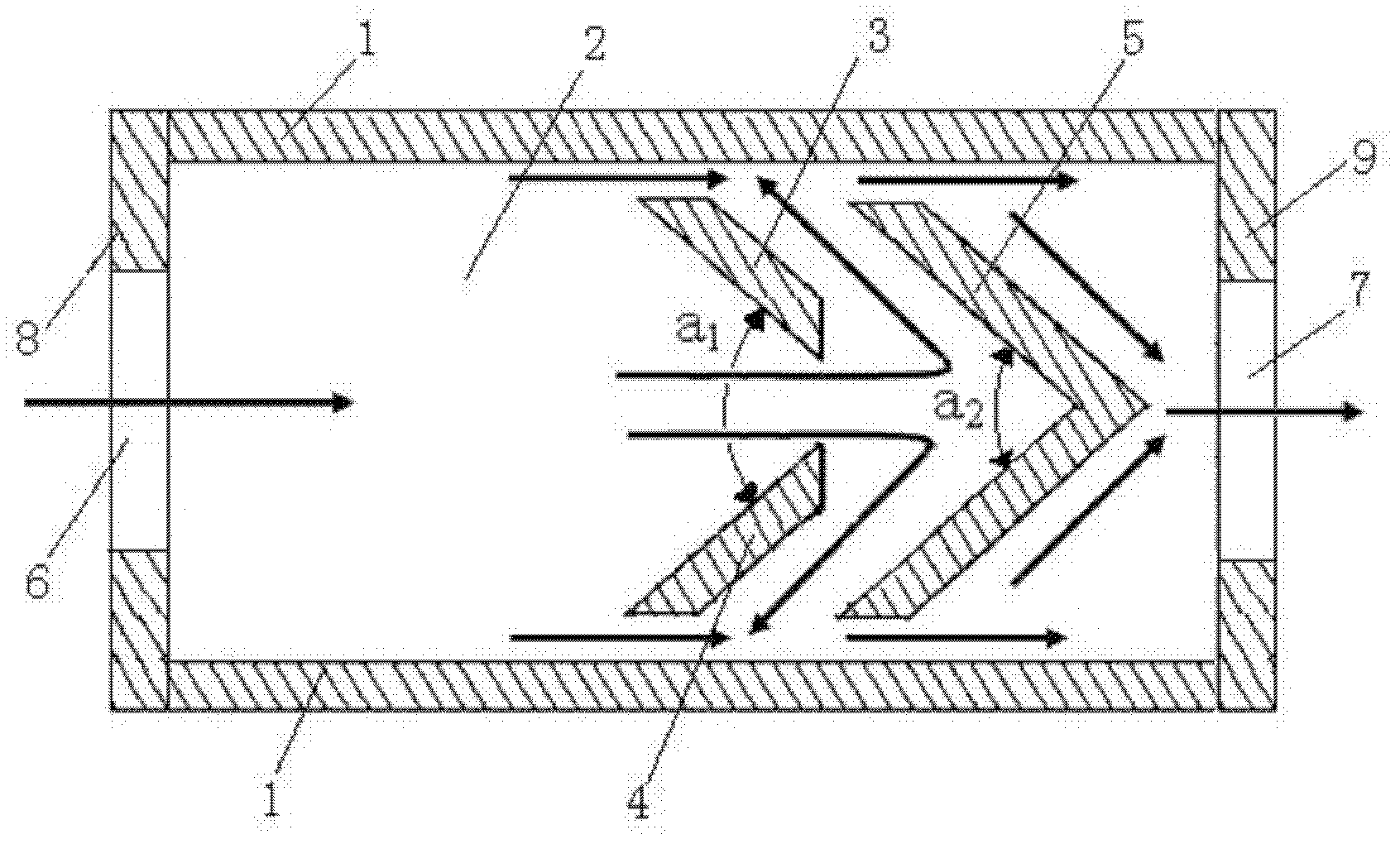

[0027] like image 3 As shown, the difference between this embodiment and Embodiment 1 is: a front baffle 8 is installed on the front end of the base plate 2, the water inlet 6 is opened on the front baffle 8, and a rear baffle 9 is installed on the rear end of the base plate 2. Water outlet 7 is opened on the tailgate 9. Wherein, there is one water inlet 6 and one water outlet 7 , and they are located on the center line of the bottom plate 2 . At this time, the top plate 10, the bottom plate 2, the front baffle plate 8, the rear baffle plate 9, the two water retaining outer walls 1, the first water diversion plate 3, the second water diversion plate 4 and the water retaining member 5 are all integral structures . The number of water inlets 6 can also be set to be multiple, and they are evenly distributed on the front baffle 8 with the center line of the bottom plate 2 as a line of symmetry, and the number and distribution of water outlets 7 are consistent with the water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com