Grid packing and packing structure

A grid packing and packing tower technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficulty, large amount of sediment, increased purification of post-processes, etc., and achieve improvement The effect of high production capacity, high specific surface area, and stable integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

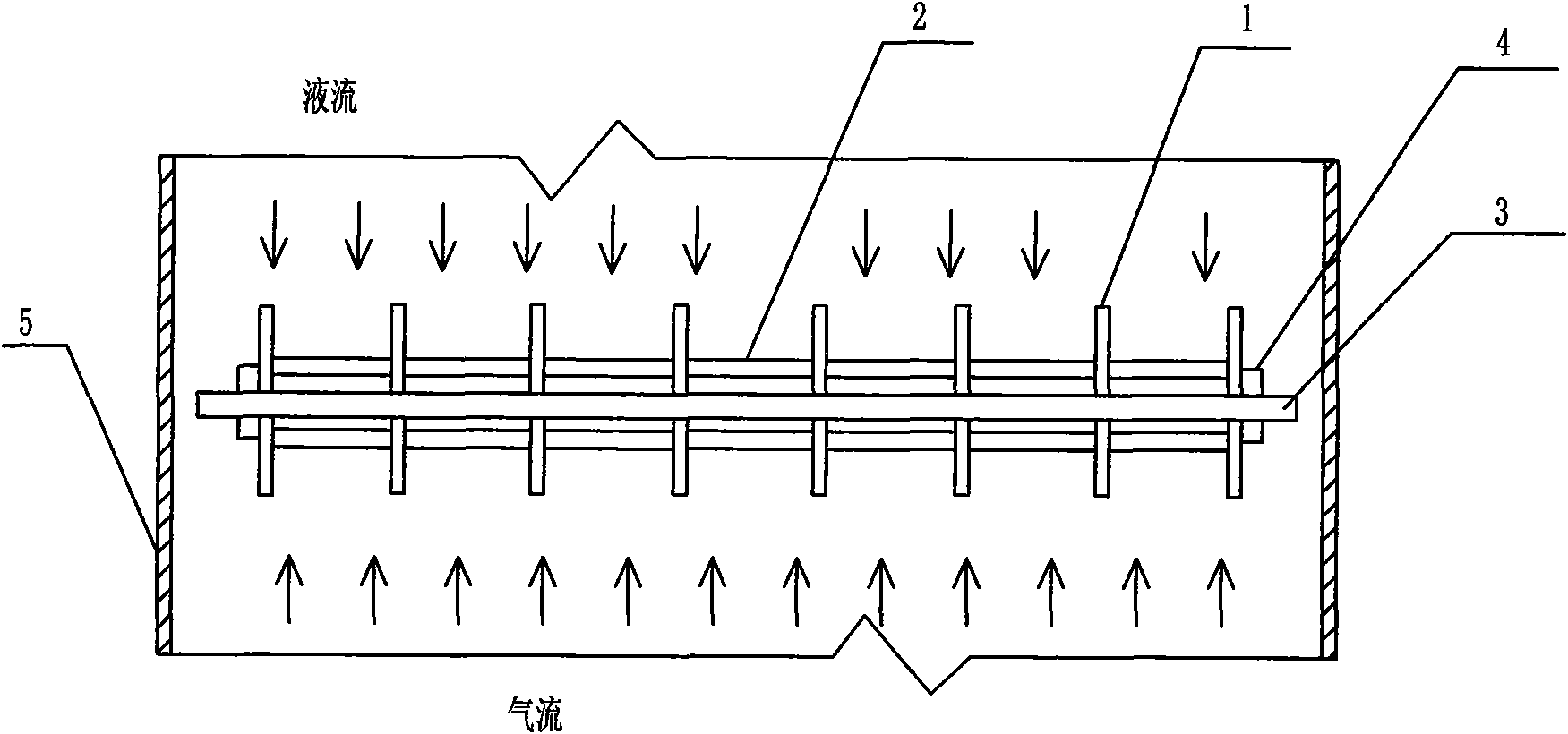

[0021] refer to figure 1 , a grid packing, comprising a plurality of grid plates 1 arranged in parallel, more than two perforations are arranged on the grid plates 1, spacer pipes 2 are arranged between every two grid plates 1, and there are other holes corresponding to the number of perforations The pull rods 3 alternately pass through the grid plate 1 and the distance tube 2, and the two ends of the pull rod 3 are provided with fasteners 4 to connect the grid plate 1 and the distance tube 2 into a whole. The pull rod 3 is a screw with threads at both ends. The fastener 4 is a nut, and the screw rod 3 is threadedly connected with the nut 4 .

[0022] The distance between the adjacent grid plates 1 is 10-60 mm. The pull rod 3 is made of metal. The grid plate 1 is provided with several through holes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com