Flow crossing-baffling composite gasoline fractionating tower of ethylene device

A fractionation tower and cross-flow technology, which is applied in the field of cross-flow-baffled composite gasoline fractionation towers, can solve the problems of high cost, coke blockage of heat exchangers, polymer blockage of liquid distributors or trays, etc., to achieve anti- Excellent plugging ability and excellent mass and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0035] Such as figure 1 As shown, the gasoline fractionation tower embodiment of this ethylene plant includes a tower body 1 and its nozzles and instruments (not shown), and the functional sections in the tower body are the quenching oil circulation section A and the medium oil circulation section from bottom to top. B. Diesel separation section C and gasoline separation section D.

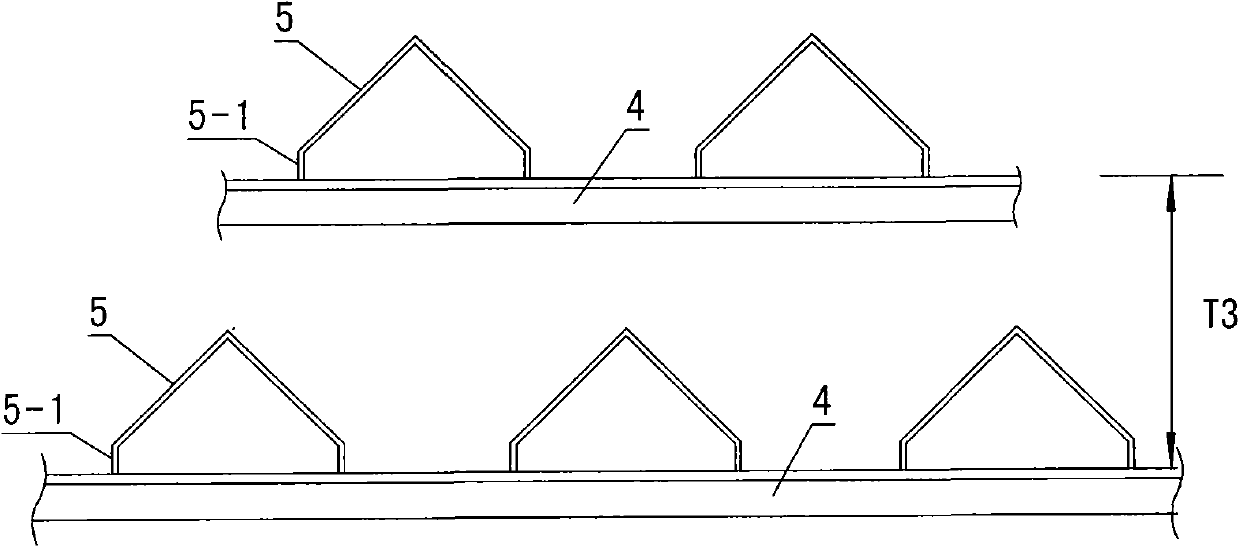

[0036] There are 10-16 layers of miniature baffles 5 between the nozzle-type liquid distributor 6 of the quenching oil circulation section A and the three-dimensional composite diversion-type inlet initial distributor 10. figure 1 In the shown embodiment, 15 layers of micro-baffles 5 are provided and supported by space grid 4. The structures of micro-baffles 5 and space grid 4 are described below respectively.

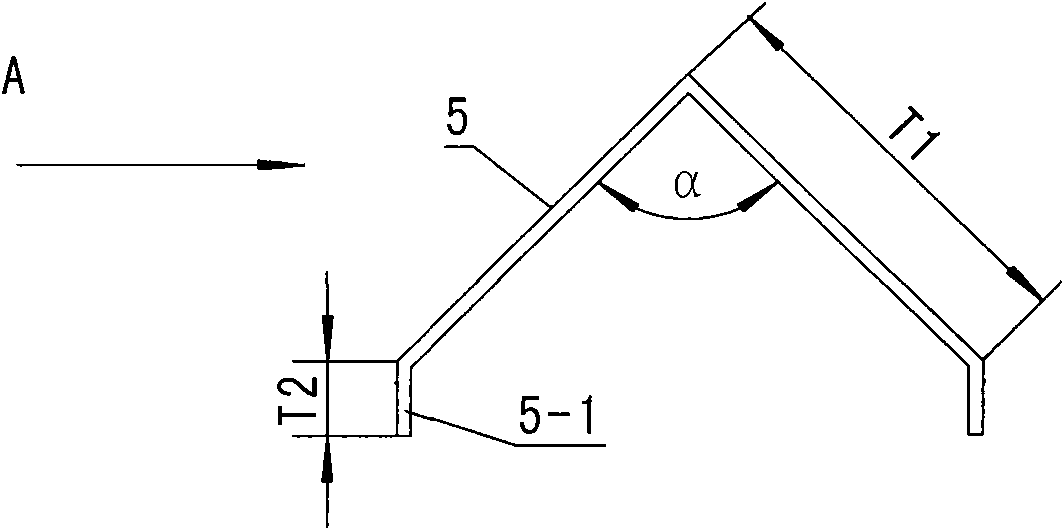

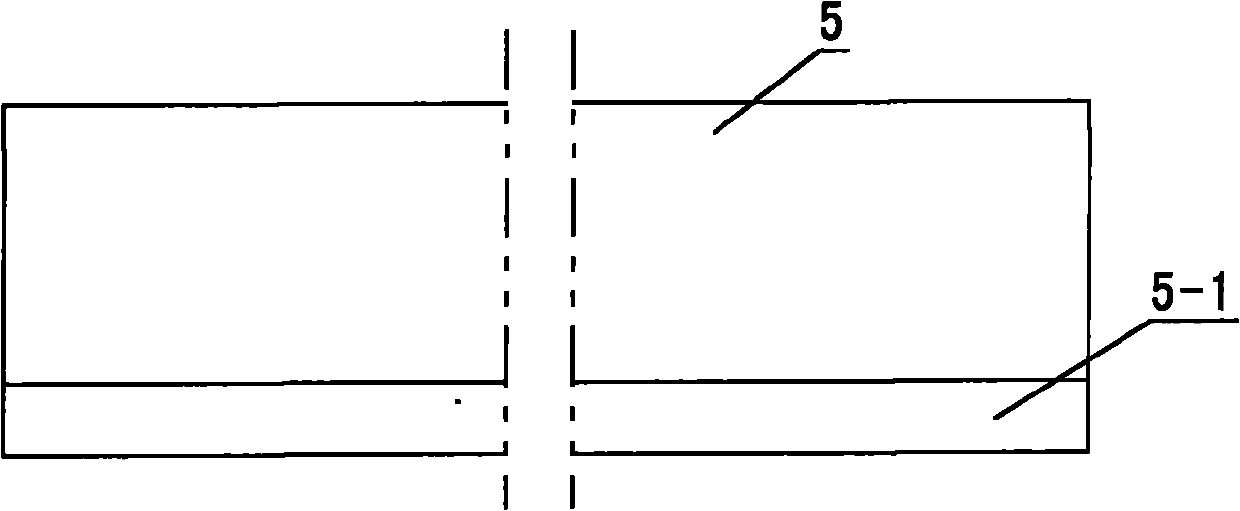

[0037] Such as figure 2 , 3 As shown, the angle range α...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com