Sieve plate device preventing hole blocking in screening blind area

A blind area and hole blocking technology, which can be used in filter screen, solid separation, dry gas arrangement, etc., can solve the problem of the need to increase the purging pressure, and achieve the effect of strong anti-blocking effect, high purging efficiency and large purging area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

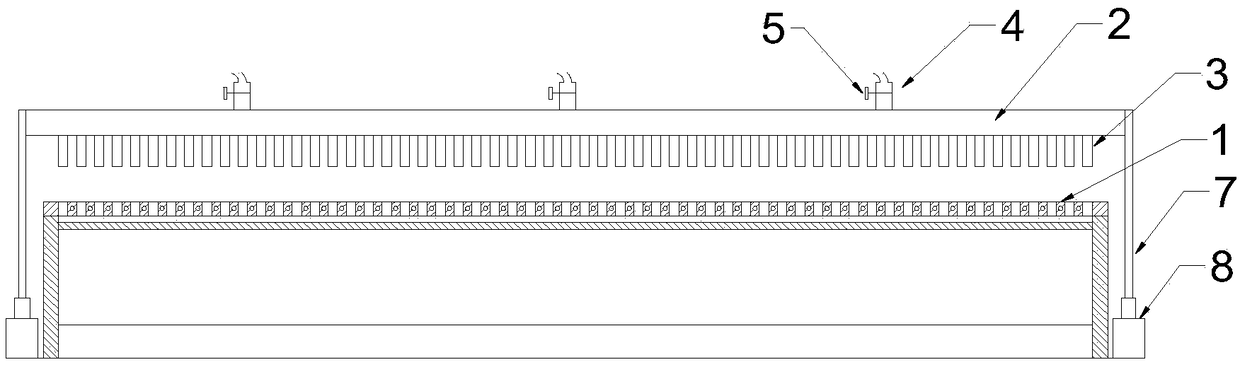

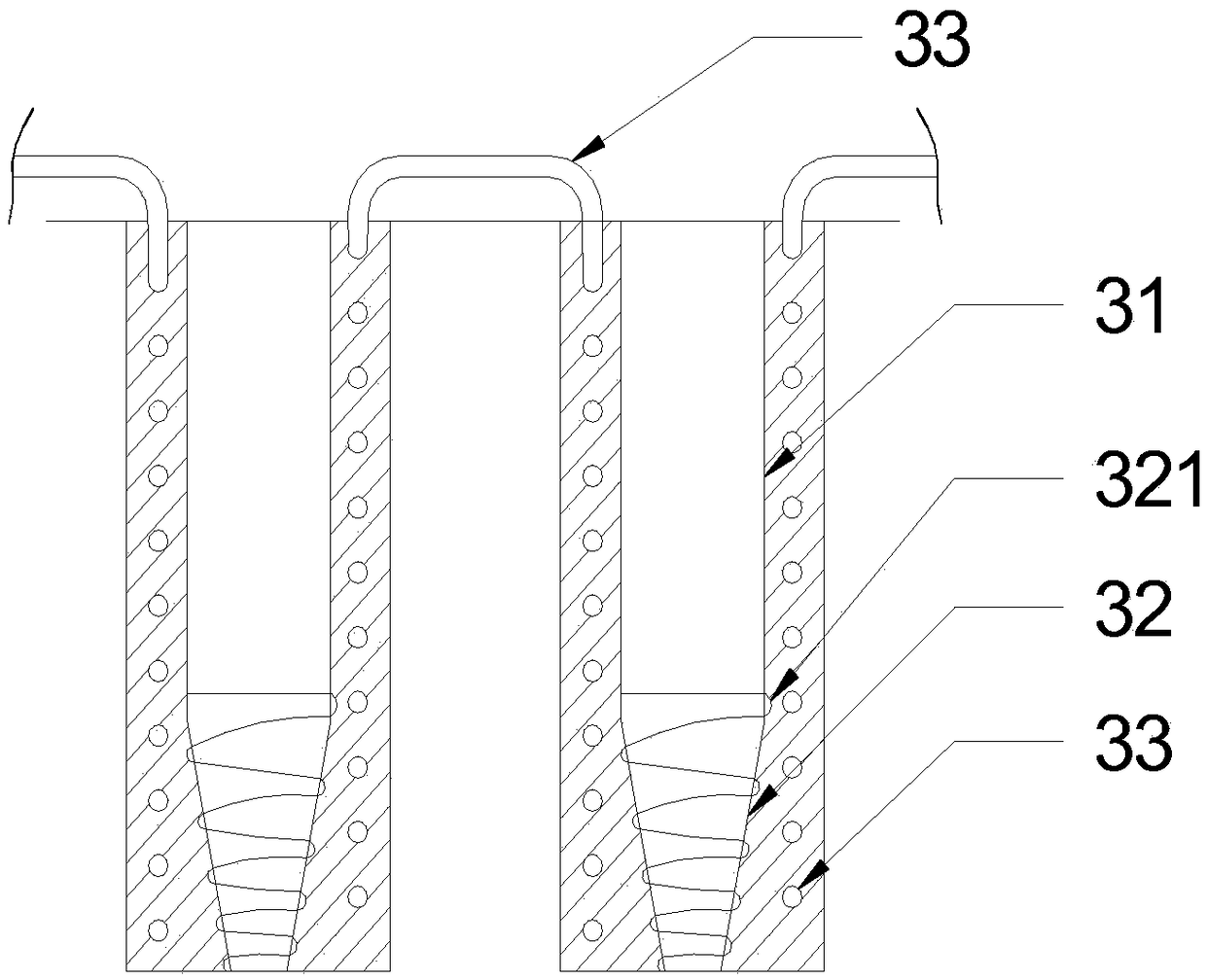

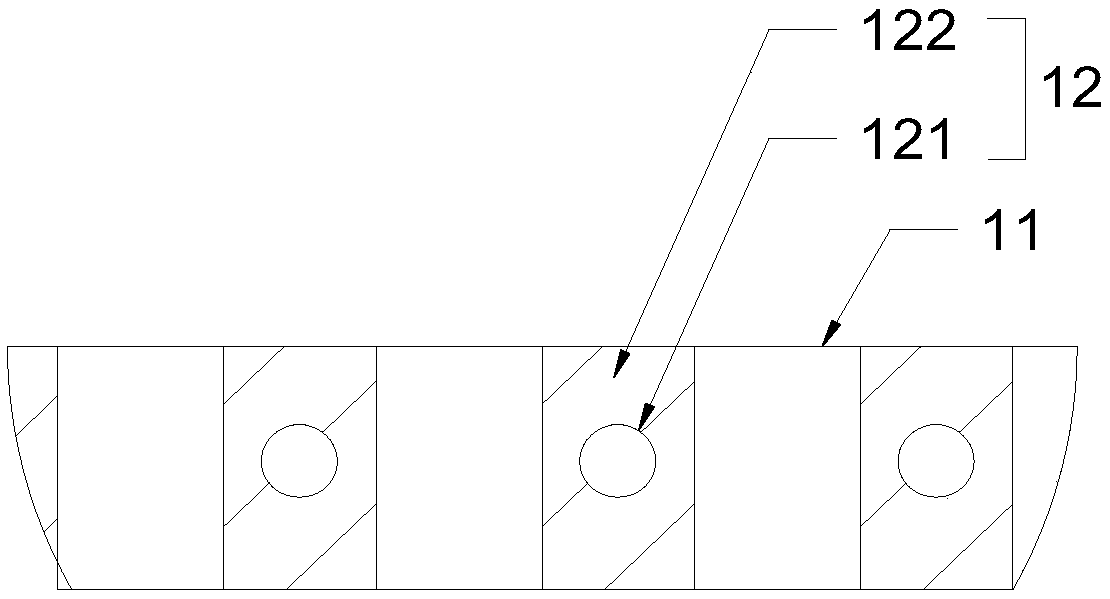

[0028] Such as figure 1 , figure 2 and Figure 5 As shown, a sieve plate device for preventing hole blocking in screening blind areas includes a pressure system and a sieve body arranged sequentially from top to bottom, and the sieve body includes a screen 1 provided with several sieve holes 11; The shape of the screen 1 matches the flat air bag 2. The bottom of the air bag 2 is provided with several needle-shaped air pipes 3 corresponding to the screen holes 11. The needle-shaped air pipe 3 includes an upper pipe end 31 communicated with the air bag 2 and The lower pipe end 32 communicating with the outside air, the pipe hole of the upper pipe end 31 is a straight cylindrical structure, and the pipe hole of the lower pipe end 32 is a cone structure with a wide top and a narrow bottom; the top of the air bag 2 is provided with a plurality of compressed air Air intake pipe 4, the compressed air intake pipe 4 is connected with the external compressed air pipeline.

[0029] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com