Anti-blocking powder conveying equipment with spraying devices

A technology of conveying equipment and equipment, applied in the field of powder conveying, can solve problems such as clogging of powder materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

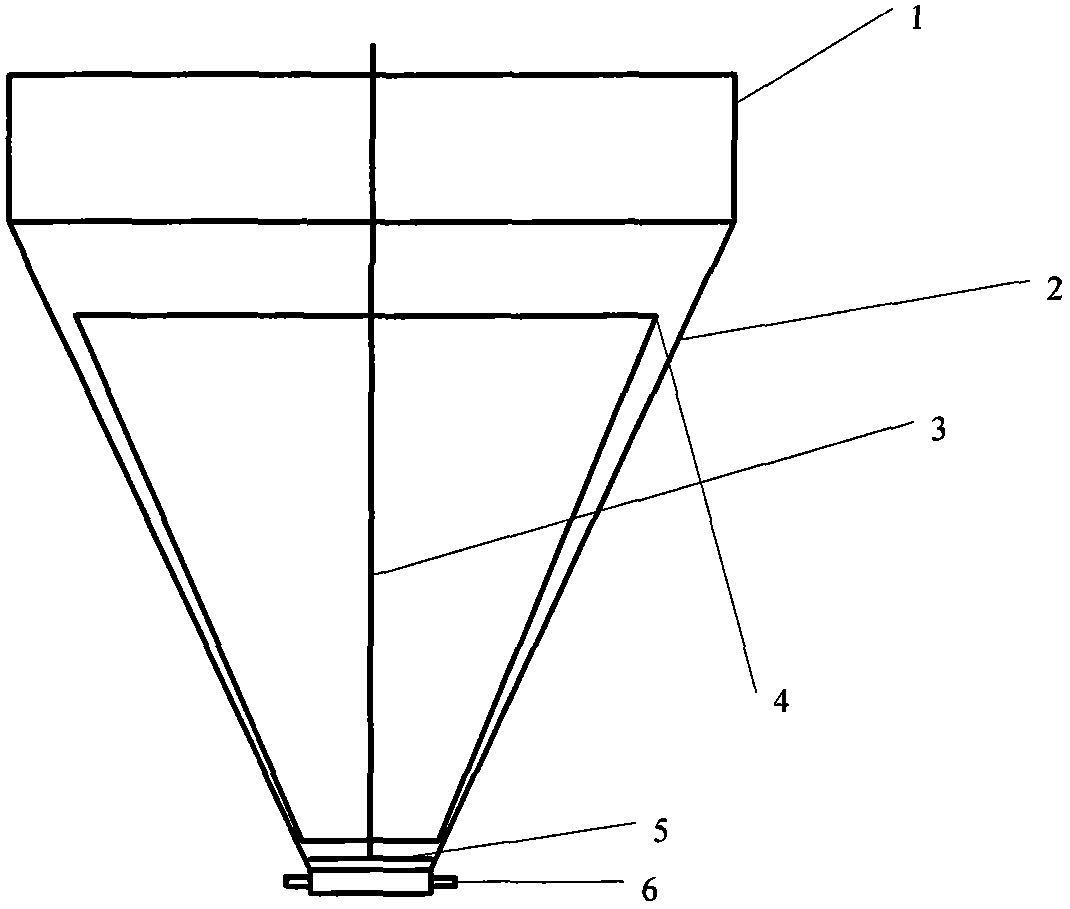

[0025] Taking pulverized coal as an example, when the flow rate drops to 70% of the normal flow rate, start the injection device 5 and blade 4 (the nozzle of the blade is not activated), the nozzle of the injection device injects gas upwards, the angle between the nozzle and the horizontal is 35°, and the measured flow rate resumes to 95% of normal flow energy consumption.

Embodiment 2

[0027] Taking pulverized coal as an example, when the flow rate drops to 70% of the normal flow rate, start the injection device 5 and blade 4 (start the nozzle of the blade at the same time, the nozzle on the blade sprays gas downward, and the angle between the nozzle and the horizontal is 75°), the injection device The nozzle sprays gas upwards, the angle between the nozzle and the horizontal is 35°, and the measured flow rate returns to 95% of the normal flow rate.

[0028] Taking the energy consumption of Comparative Example 1 as 1, calculate the energy consumption of other Comparative Examples and Examples, see Table 1.

[0029]

[0030] It can be seen from the table that having both blades and injection equipment can reduce the energy consumption of anti-blocking.

Embodiment 3

[0032] Taking pulverized coal as an example, when the flow rate drops to 70% of the normal flow rate, start the injection device 5 and blade 4 (the nozzle of the blade is not activated), the nozzle of the injection device injects gas upwards, and the angle between the nozzle and the horizontal is 15, 25, 35, 45, 55°. Measure the energy consumption at which flow returns to 95% of normal flow. Taking the energy consumption of an included angle of 15° as 1, calculate the energy consumption of other included angles, see Table 2.

[0033]

[0034] As can be seen from the table, 35° has the lowest energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com