PTA device oxidation unit air supply system anti-blocking back-blowing system

An air supply and conveying valve technology, which is applied in the field of anti-blocking and back-blowing system of the air supply system of the oxidation unit of the PTA device, can solve the problems of not considering all the components of the oxidized product materials, the large dust pollution of the surrounding environment, and the compression of the company's profit space, etc. Achieve the effect of effectively utilizing the pipeline layout space, facilitating personnel operation, and convenient manufacturing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

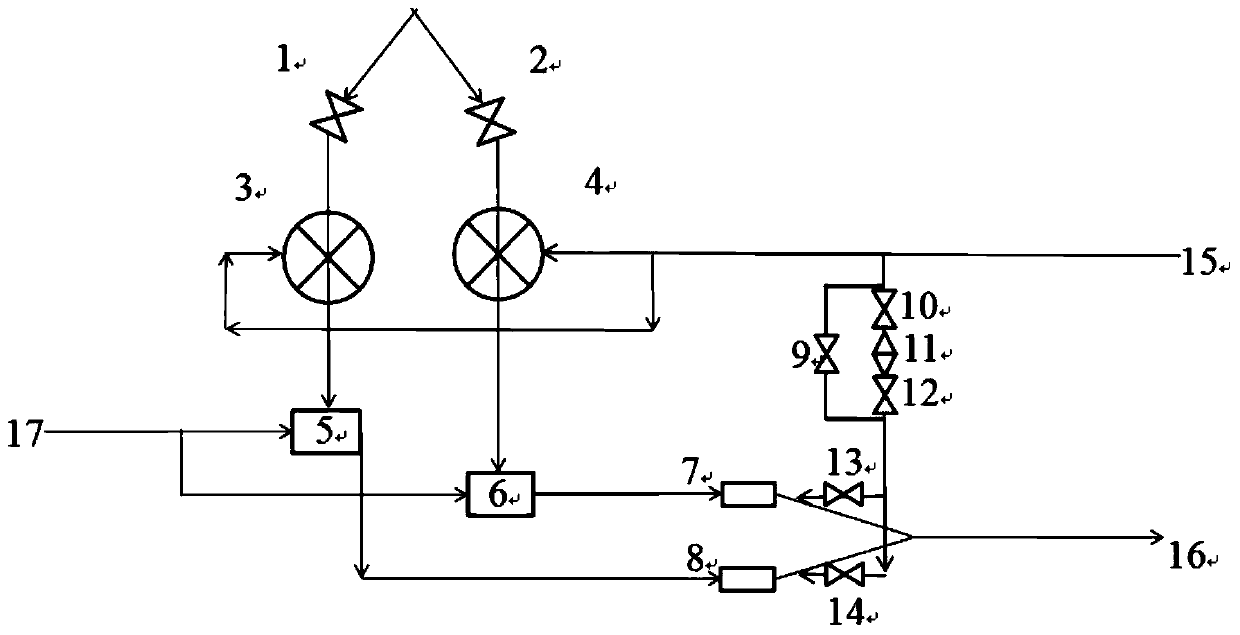

[0023] Such as figure 1 As shown, the present invention provides a product delivery system applicable to various PTA production devices. The product is separated through a vacuum filter and the solid product is passed through a rotary steam tube dryer (not shown in the figure) through the blanking pipeline bolt flange form There are two process routes, one for use and one for standby during normal production:

[0024] The first route: the feeding pipeline, the first feeding knife valve 1, the first conveying rotary valve 3, the first material mixer 5, the first conveying outlet knife valve 8, and the product conveying downstream system 16 (silo) are sequentially connected.

[0025] The second route: the feeding pipeline, the second feeding knife valve 2, the second conveying rotary valve 4, the second material mixer 6, the second conveying outlet knife valve 7, and the product conveying downstream system (silo) 16 are sequentially connected.

[0026] The first feeding knife v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com