Intelligent blocking cleaning nozzle-containing blade rotating solid material conveying method

A solid material and blade technology, applied in the field of solid material conveying, can solve the problem of powder material blockage, reduce energy consumption and improve the efficiency of blocking prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

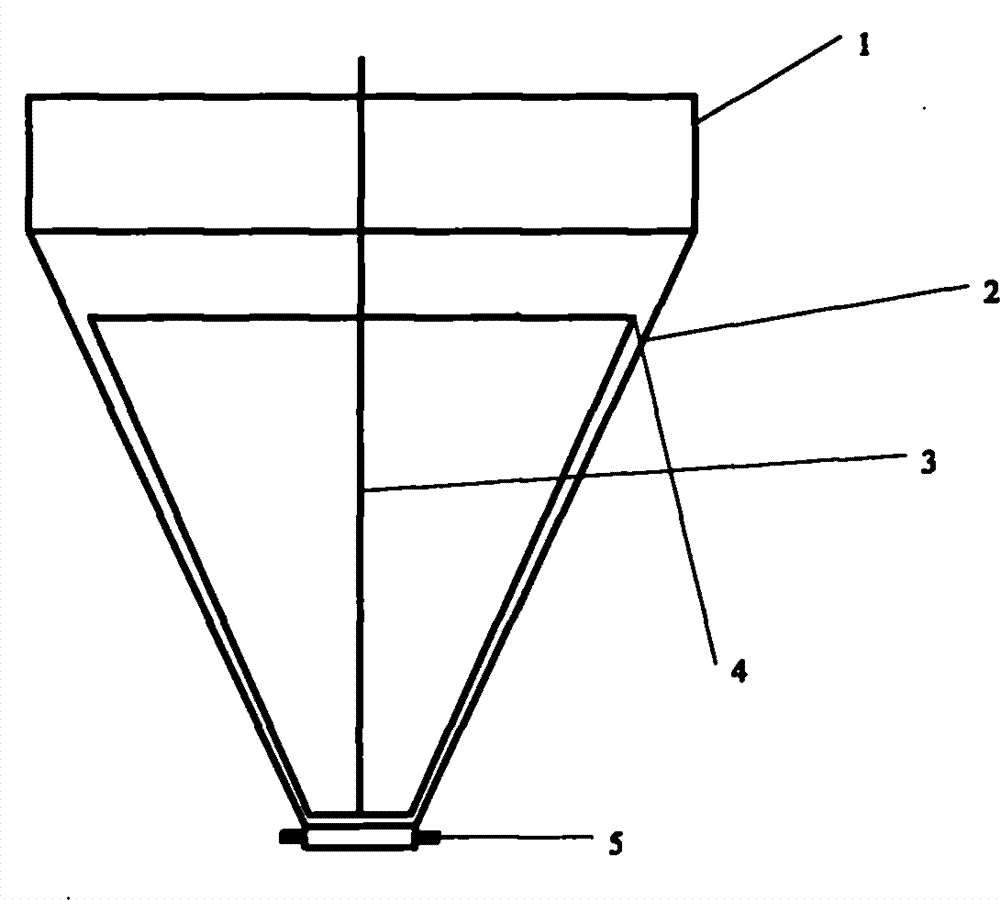

Image

Examples

Embodiment 1

[0021] Taking pulverized coal as an example, when the flow rate drops to 70% of the normal flow rate, the rotating shaft 3 is started (the nozzle of the blade is not started), and the gap between the blade and the inner wall of the lower feeding section 2 accounts for 0.1% of the radius (inner diameter) of the lower feeding section , 0.3%, 1.0%, 1.6%, 3.3%, 6.6%, 10%, 15%. Measure the energy consumption at which flow returns to 95% of normal flow. Taking the energy consumption of 0.3% as 1, calculate the energy consumption of other proportions, see Table 1.

[0022]

0.1%

0.3%

1.0%

1.6%

3.3%

6.6%

10%

15%

energy consumption

100%

95%

85%

70%

95%

110%

[0023] Among them, 0.1% of the gaps were alarmed by the pressure sensor during the third test, and the blades were checked to be loose; 15% of them could not be restored to 95% of the normal flow.

[0024] Using 3.3% gap ...

Embodiment 2

[0026] Take pulverized coal as an example, when the flow rate drops to 70% of the normal flow rate, start the rotating shaft 3 (start the nozzle of the blade at the same time, the nozzle on the blade sprays gas downward, the angle between the nozzle and the horizontal is 75°, the blade and the lower feeding section 2 The gap on the inner wall accounts for 3.3% of the radius (inner diameter) of the lower feeding section), and the measured flow rate returns to 95% of the normal flow rate.

[0027] Taking the energy consumption of Example 1 as 1, calculate the energy consumption of Example 2, see Table 2.

[0028]

[0029] It can be seen from the table that starting the nozzle on the blade while the blade is rotating can reduce the energy consumption of anti-blocking.

Embodiment 3

[0031] Take pulverized coal as an example, when the flow rate drops to 70% of the normal flow rate, start the rotating shaft 3 (start the nozzle of the blade at the same time, the gap between the blade and the inner wall of the lower feeding section 2 accounts for 3.3% of the radius (inner diameter) of the lower feeding section) , wherein the nozzles on the blades spray gas downwards, and the included angles between the nozzles and the horizontal are 15, 35, 55, 75, 95°. Measure the energy consumption at which flow returns to 95% of normal flow. Taking the energy consumption of an included angle of 15° as 1, calculate the energy consumption of other included angles, see Table 3.

[0032]

[0033] As can be seen from the table, 75° has the lowest energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com