A cluster rectification device with side line reactor

A reactor and sideline technology, applied in the field of cluster rectification devices, can solve the problems of low reaction conversion rate and product yield, large volume of rectification tower, and high input cost, and achieves convenient loading, low input cost and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

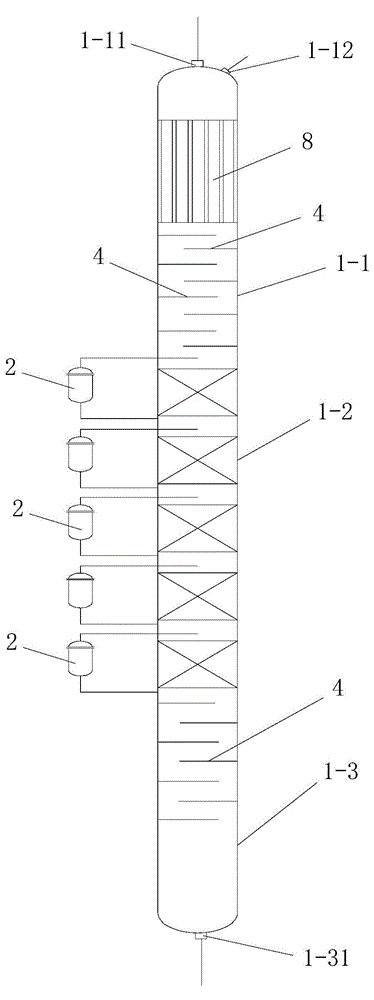

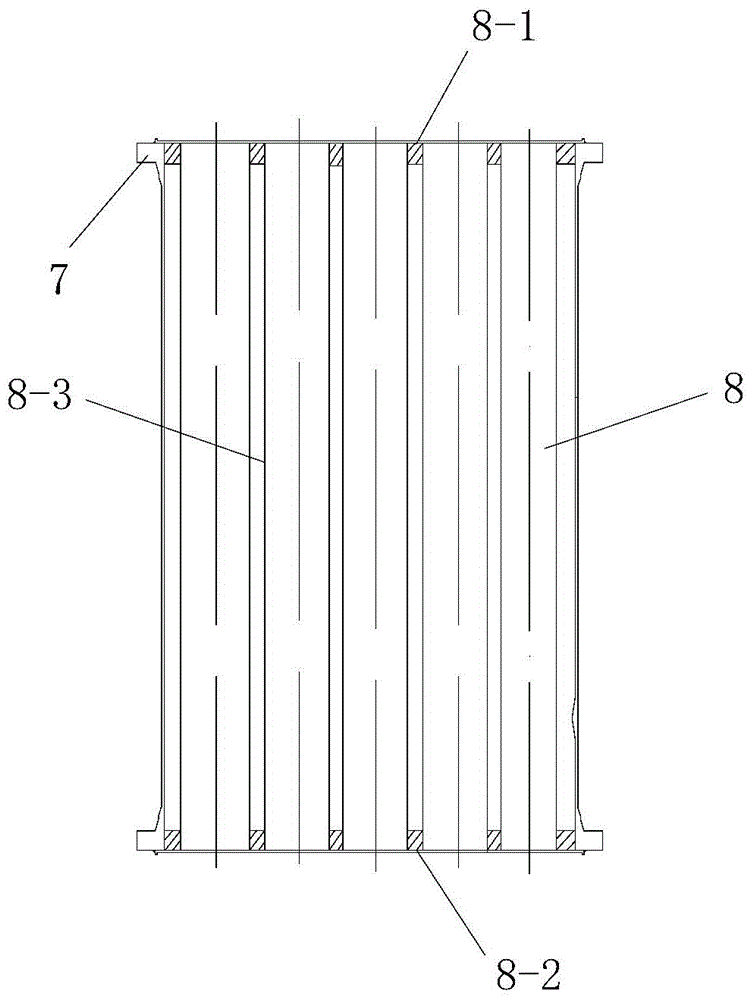

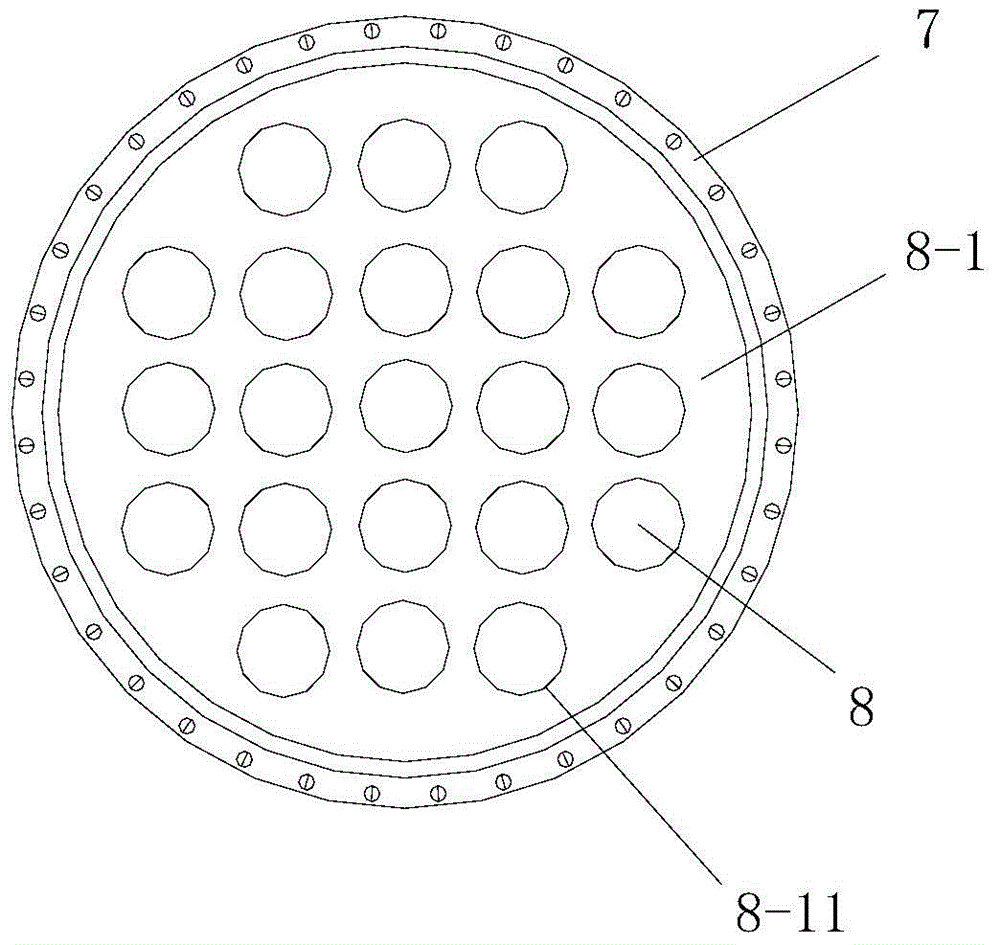

[0060] Such as figure 1 As shown, the present invention includes a vertically arranged rectification tower body and a plurality of side line reactors 2 arranged outside the rectification tower body, and the plurality of side line reactors 2 are arranged from top to bottom. The rectifying tower body comprises an upper tower body 1-1, a lower tower body 1-3 positioned directly below the upper tower body 1-1 and a tower connected between the upper tower body 1-1 and the lower tower body 1-3 Middle tower body 1-2. The upper part of the upper tower body 1-1 is a cluster rectification section and its lower part is an upper tray arrangement section, and the cluster rectification section is divided into a plurality of cluster rectification zones 8 arranged vertically. The upper tray arrangement section and the top of the upper tower body 1-1 are connected through a plurality of said cluster rectification zones, each of said cluster rectification zones is a small-bore rectification to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com