Automatic material dividing device with anti-blocking function

A technology of a material distribution device and a driving device is applied in the directions of fuel supply, transportation and packaging, block/powder supply/distribution, etc. Simple, high efficiency of material distribution, strong anti-blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

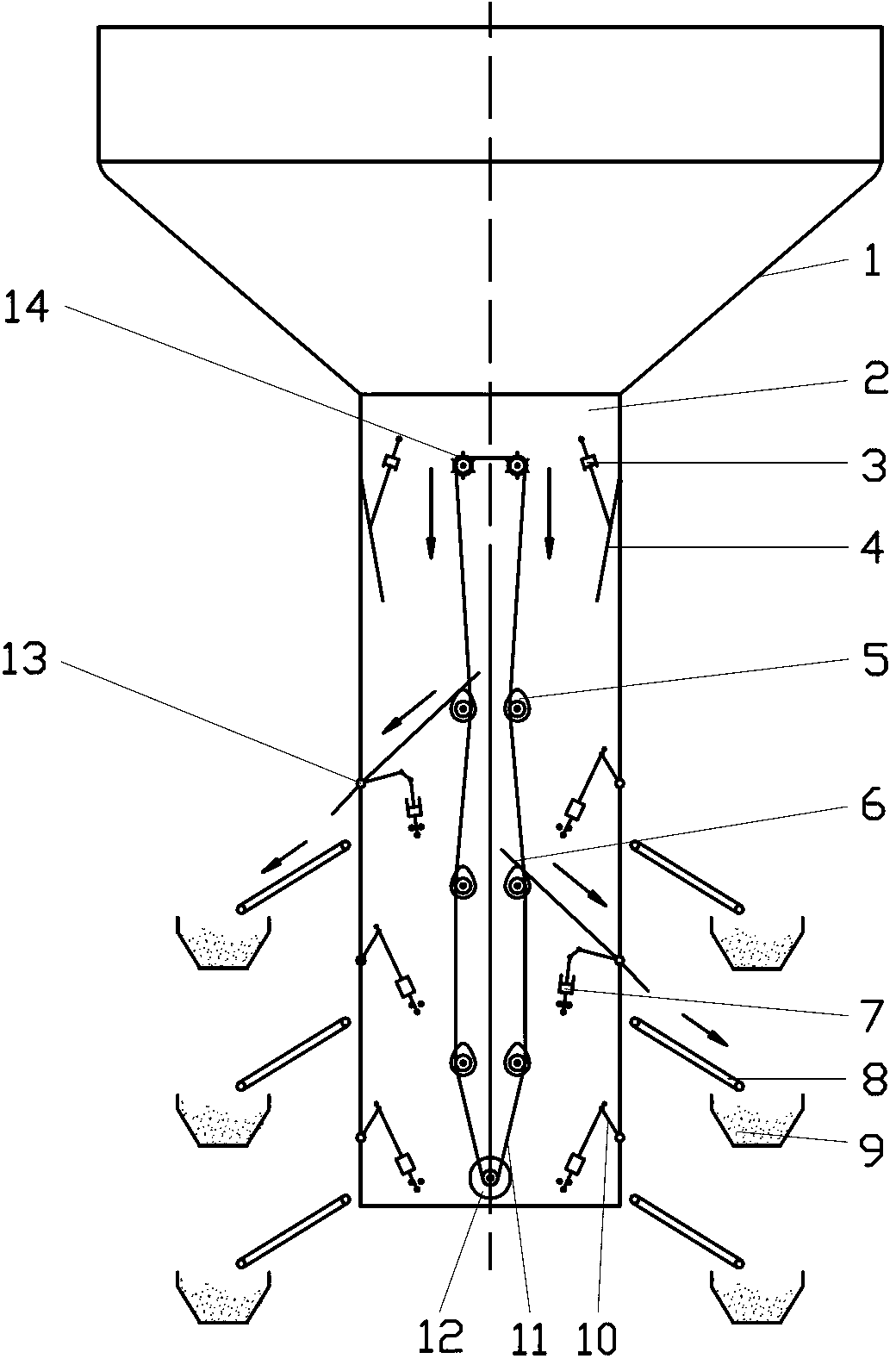

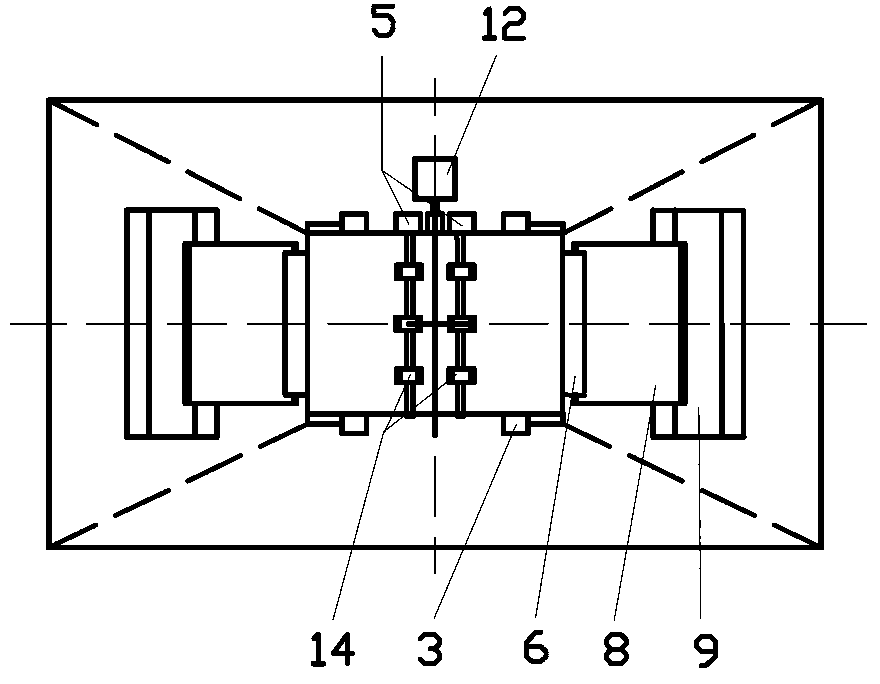

[0026] figure 1 It is a structural schematic diagram of double-side feeding in Embodiment 1 of the automatic material distributing device with anti-blocking function of the present invention.

[0027] In this embodiment, there are 6 distributing units, 3 distributing wheels, and the distance between the distributing wheels and the symmetrical center of the distributing box is 1.5 d, and the distributing units and distributing wheels are arranged symmetrically on both sides of the distributing box . After the required feeding equipment is determined, the driving device of the material distribution plate (in this embodiment, the driving device is a cylinder) 7 respectively opens the corresponding material distribution plate 6 (both sides feed, one material distribution plate is opened on each side, and the rest are closed) After the action of the material distribution plate is completed, the driving device of the material baffle (in this embodiment, the driving device is a cyli...

Embodiment 2

[0031] Figure 4 It is a structural schematic diagram of double-side feeding in Embodiment 2 of the automatic material distributing device with anti-blocking function of the present invention.

[0032]In this embodiment, there are 4 distributing units, 2 distributing wheels, and the distance between the distributing wheels and the symmetrical center of the distributing box is 1.7 d, and the distributing units and distributing wheels are arranged symmetrically on both sides of the distributing box . After the required feeding equipment is determined, the driving device of the material distribution plate (in this embodiment, the driving device is a cylinder) 7 respectively opens the corresponding material distribution plate 6 (both sides feed, one material distribution plate is opened on each side, and the rest are closed) After the action of the material distribution plate is completed, the driving device of the material baffle (in this embodiment, the driving device is a cyli...

Embodiment 3

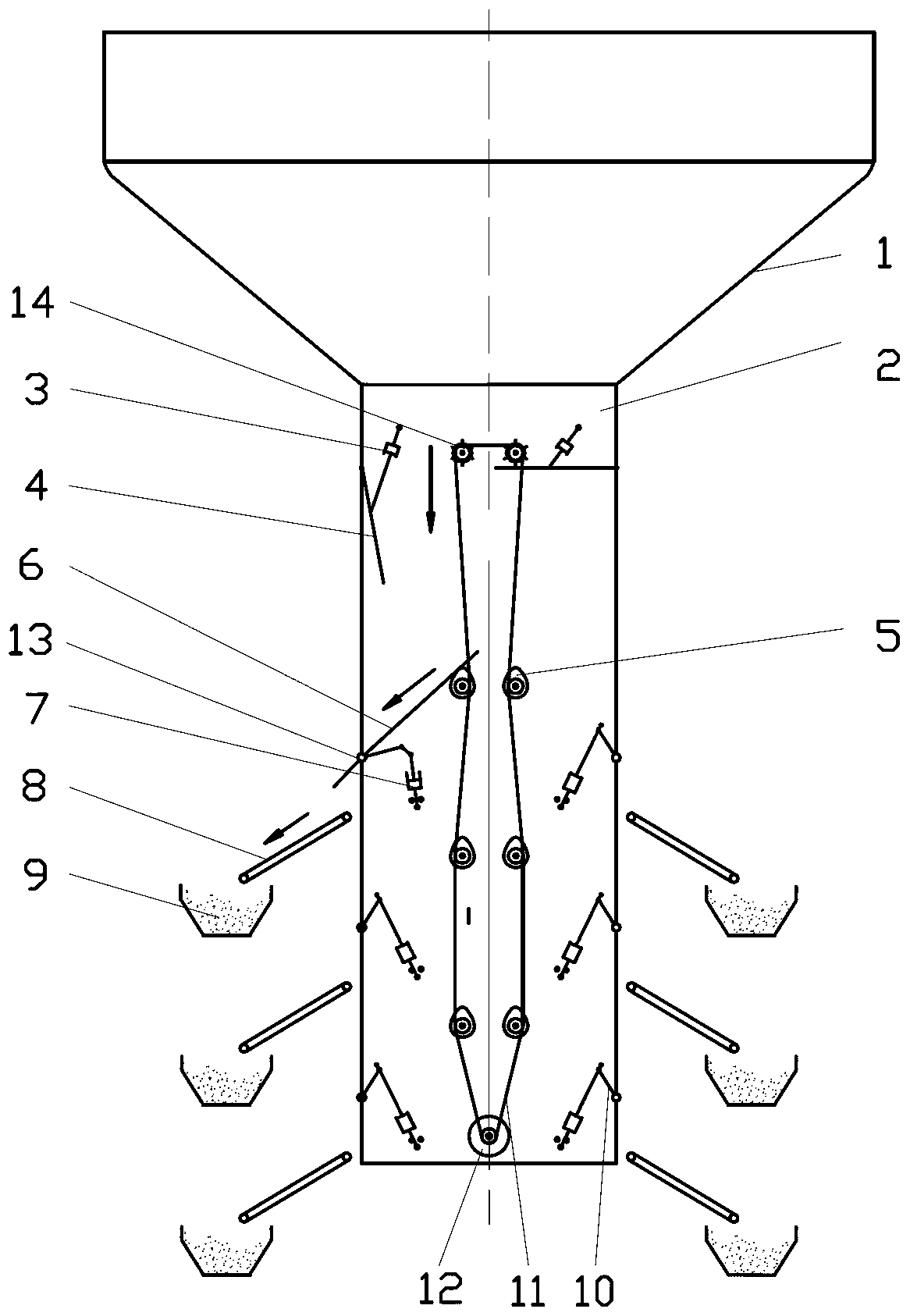

[0034] Figure 7 It is a structural schematic diagram of double-side feeding in Embodiment 3 of the automatic material distributing device with anti-blocking function of the present invention.

[0035] In this embodiment, there are 8 distributing units, 4 distributing wheels, and the distance between the distributing wheels and the symmetrical center of the distributing box is 2 d, and the distributing units and distributing wheels are arranged symmetrically on both sides of the distributing box . After the required feeding equipment is determined, the driving device of the material distribution plate (in this embodiment, the driving device is a cylinder) 7 respectively opens the corresponding material distribution plate 6 (both sides feed, one material distribution plate is opened on each side, and the rest are closed) After the action of the material distribution plate is completed, the driving device of the material baffle (in this embodiment, the driving device is a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com