PZT-base anti-ferroelectric material based on rolling membrane process and preparation method of PZT-base anti-ferroelectric material

An antiferroelectric and rolling film technology, which is applied in the field of PZT-based antiferroelectric materials and its preparation, can solve the problems of low breakdown field strength, poor internal uniformity, and poor compactness, so as to improve the breakdown field strength, The steps are simple and easy to improve the effect of energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

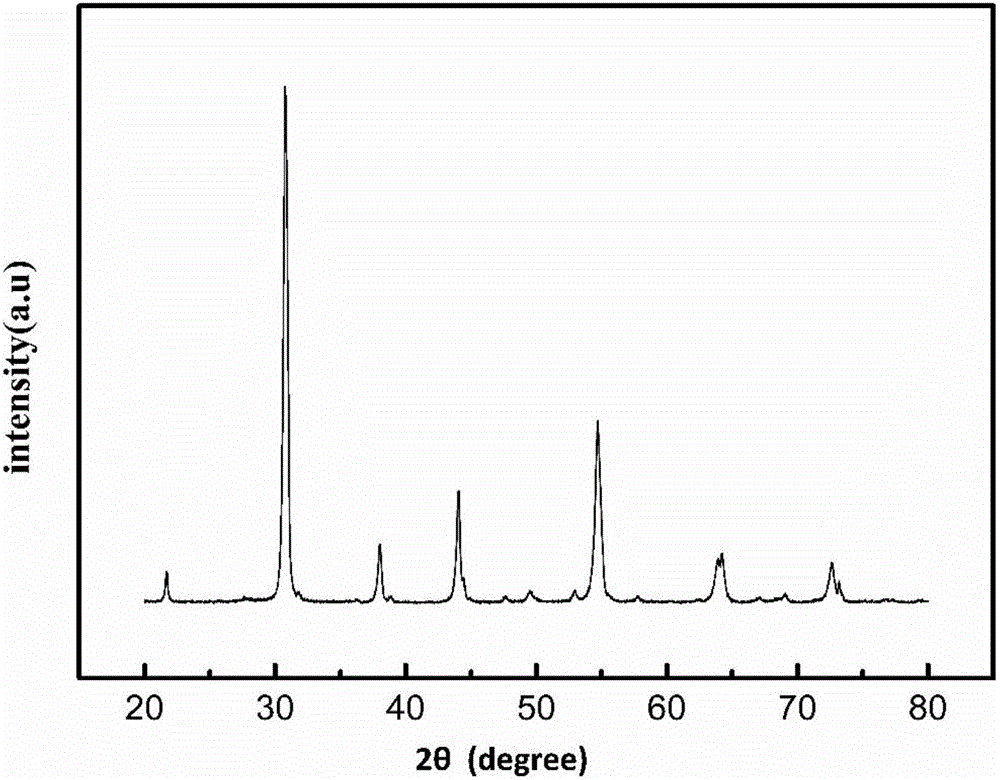

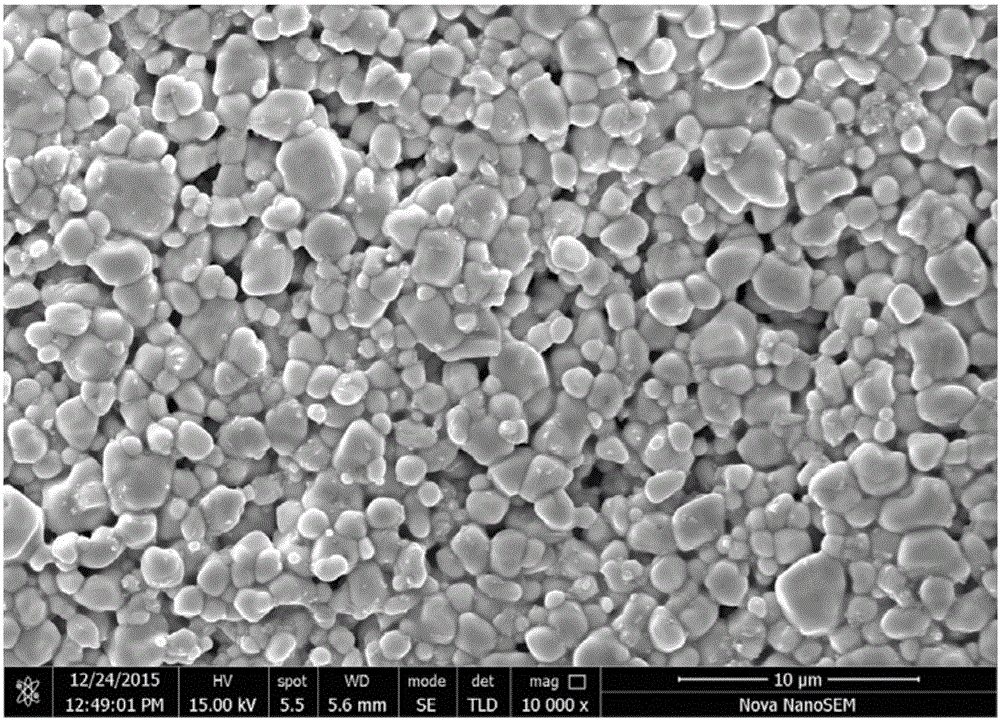

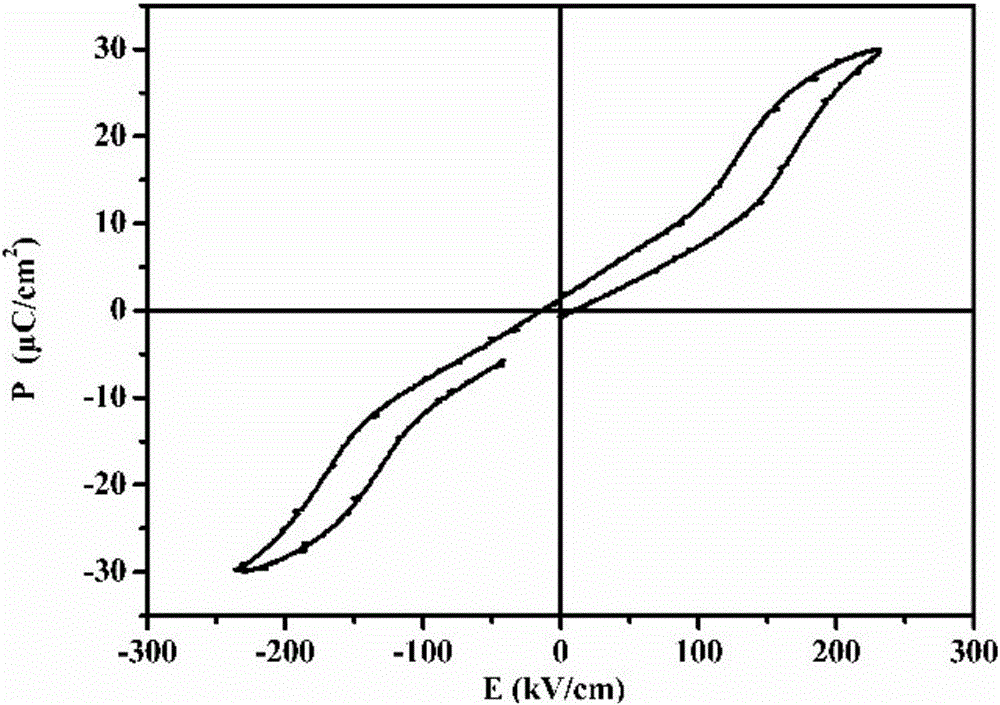

[0033]The purity is analytically pure lead oxide, lanthanum oxide, zirconium oxide, tin oxide and titanium oxide, according to the stoichiometric ratio (Pb 0.97 La 0.02 )(Zr 0.29 sn 0.65 Ti 0.06 )O 3 Weigh the ingredients, put the prepared ingredients into the ball mill tank, the ball to material ratio is 3:1, add deionized water to about 2 / 3 of the ball mill tank volume. The ball milling time is 12 hours. After the ball milling, take it out and dry it, pre-burn it at 900°C for 2 hours, then ball mill it again for 12 hours, and sieve. Add 30% binder, first repeat rough rolling on the rolling machine for 1 hour, and finally finish rolling to 0.1mm, cut into square pieces of 10mm*10mm, put in the furnace at 600°C for 4h, and the heating rate is 1°C per minute . Finally, put the biscuit sheet after degumming into the airtight aluminum oxide dry pot, and add an appropriate amount of (Pb 0.97 La 0.02 )(Zr 0.29 sn 0.65 Ti 0.06 )O 3 powder to avoid the loss of lead. Then...

Embodiment 2

[0035] The purity is analytically pure lead oxide, lanthanum oxide, zirconium oxide, tin oxide and titanium oxide, according to the stoichiometric ratio (Pb 0.97 La 0.02 )(Zr 0.26 sn 0.68 Ti 0.06 )O 3 Weigh the ingredients, put the prepared ingredients into the ball mill tank, the ratio of ball to material is 3:1, add deionized water to 2 / 3 of the volume of the ball mill tank. The ball milling time is 12 hours. After the ball milling, take it out and dry it, pre-burn it at 920°C for 2 hours, then ball mill it again for 12 hours, and sieve it. Add 30% binder, first repeat the rough rolling on the film rolling machine for 1.5h, and finally finish rolling to 0.1mm, cut into square pieces of 10mm*10mm, put it in the furnace at 600°C for 4h, the heating rate is 1°C per minute. Finally, put the biscuit sheet after degumming into the airtight aluminum oxide dry pot, and add an appropriate amount of (Pb 0.97 La 0.02 )(Zr 0.26 sn 0.68 Ti 0.06 )O 3 powder to avoid the loss o...

Embodiment 3

[0038] The purity is analytically pure lead oxide, lanthanum oxide, zirconium oxide, tin oxide and titanium oxide, according to the stoichiometric ratio (Pb 0.97 La 0.02 )(Zr 0.5 sn 0.44 Ti 0.06 )O 3 Weigh the ingredients, put the prepared ingredients into the ball mill tank, the ratio of ball to material is 3:1, add absolute ethanol to about 2 / 3 of the volume of the ball mill tank. The ball milling time is 12 hours. After the ball milling, take it out and dry it, pre-burn it at 920°C for 2 hours, then ball mill it again for 12 hours, and sieve it. Add 30% binder, first repeat rough rolling on the rolling machine for 1 hour, and finally finish rolling to 0.1mm, cut into square pieces of 10mm*10mm, put in the furnace at 600°C for 4h, and the heating rate is 1°C per minute . Finally, put the biscuit sheet after degumming into the airtight aluminum oxide dry pot, and add an appropriate amount of (Pb 0.97 La 0.02 )(Zr 0.5 sn 0.44 Ti 0.06 )O 3 powder to avoid the loss o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com