Precast slab construction member

A technology of prefabricated panels and components, applied in building components, floor slabs, building structures, etc., can solve the problems of troublesome structural connection, poor integrity, and cumbersome components, saving materials and labor, easy transportation and installation, and high overall strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

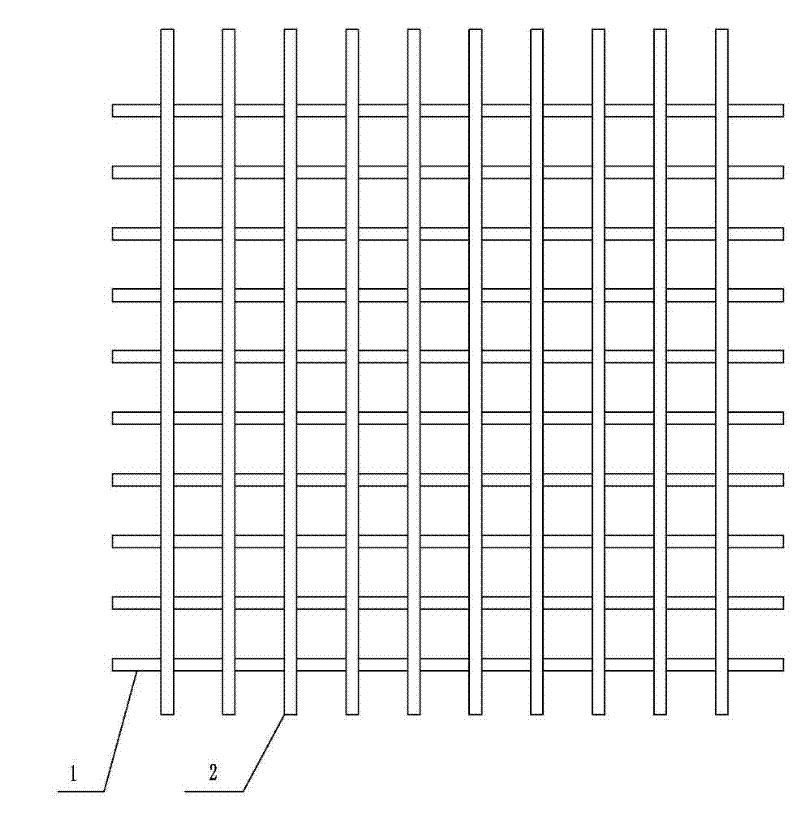

[0029] like figure 1 , figure 2 and image 3 As shown, a prefabricated slab construction component includes an upper layer of steel mesh and a lower layer of steel mesh. Both the upper and lower layers of steel mesh are composed of transverse bars 1 and longitudinal bars 2. Both the transverse bars 1 and the longitudinal bars 2 are HRB500 hot-rolled ribbed bars. The diameter 15mm, the yield strength is not less than 500Mpa, the horizontal reinforcement 1 is arranged in parallel first, and then the longitudinal reinforcement 2 is arranged in parallel, so that the horizontal reinforcement 1 and the longitudinal reinforcement 2 intersect, the angle at the intersection is 90 degrees, and the intersection is fixed by welding, or the longitudinal reinforcement 2 is arranged first , and then lay out the transverse bar 1, the upper and lower steel meshes are laid out in the same way to form the same mesh surface, and then the lower layer of steel mesh is selected as the bottom surfa...

Embodiment 2

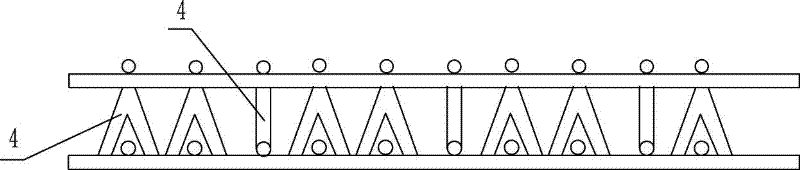

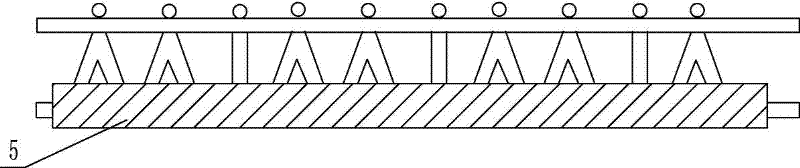

[0031] like Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, select steel bars of the same material as in Example 1, and use the same method to lay out transverse bars 1 and longitudinal bars 2, because the upper area of the floor is the compression area, and the lower area is the tension area, and the compression area is subject to greater pressure and less tension. , so the density of the upper layer of reinforcement mesh should be smaller than that of the lower layer of reinforcement mesh, and the spacing of the upper layer of reinforcement mesh is four times that of the lower layer of reinforcement mesh. The shear stud 3 is welded into a V-shape by two steel bars, and one end of the two steel bars is welded together to form the top of the shear stud 3, and the two points at the bottom are welded to a horizontal bar 1 or a longitudinal bar 2 of the lower steel mesh, The top of the shear stud 3 is welded and fixed to the upper layer of steel mesh. In order to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com