Supersonically reinforced yolk phospholipid extracting process

A technology of egg yolk lecithin and its extraction method, which is applied in the field of extracting egg yolk lecithin from egg yolk powder by means of ultrasonic enhanced extraction technology, can solve the problems of low lecithin extraction yield, large consumption of organic solvents, and limitations of industrial application, etc. Achieve the effects of easy industrial production, low extraction cost, and promotion of mass transfer and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

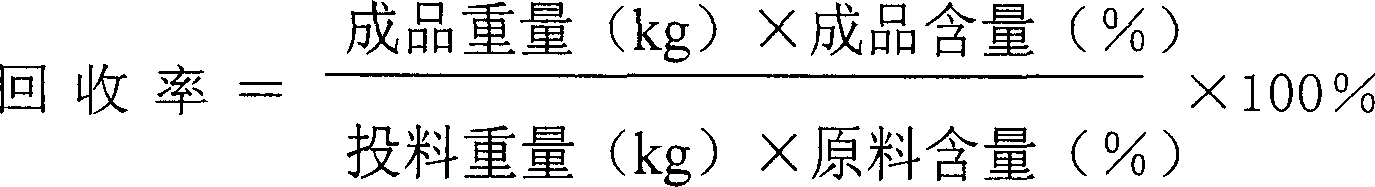

Method used

Image

Examples

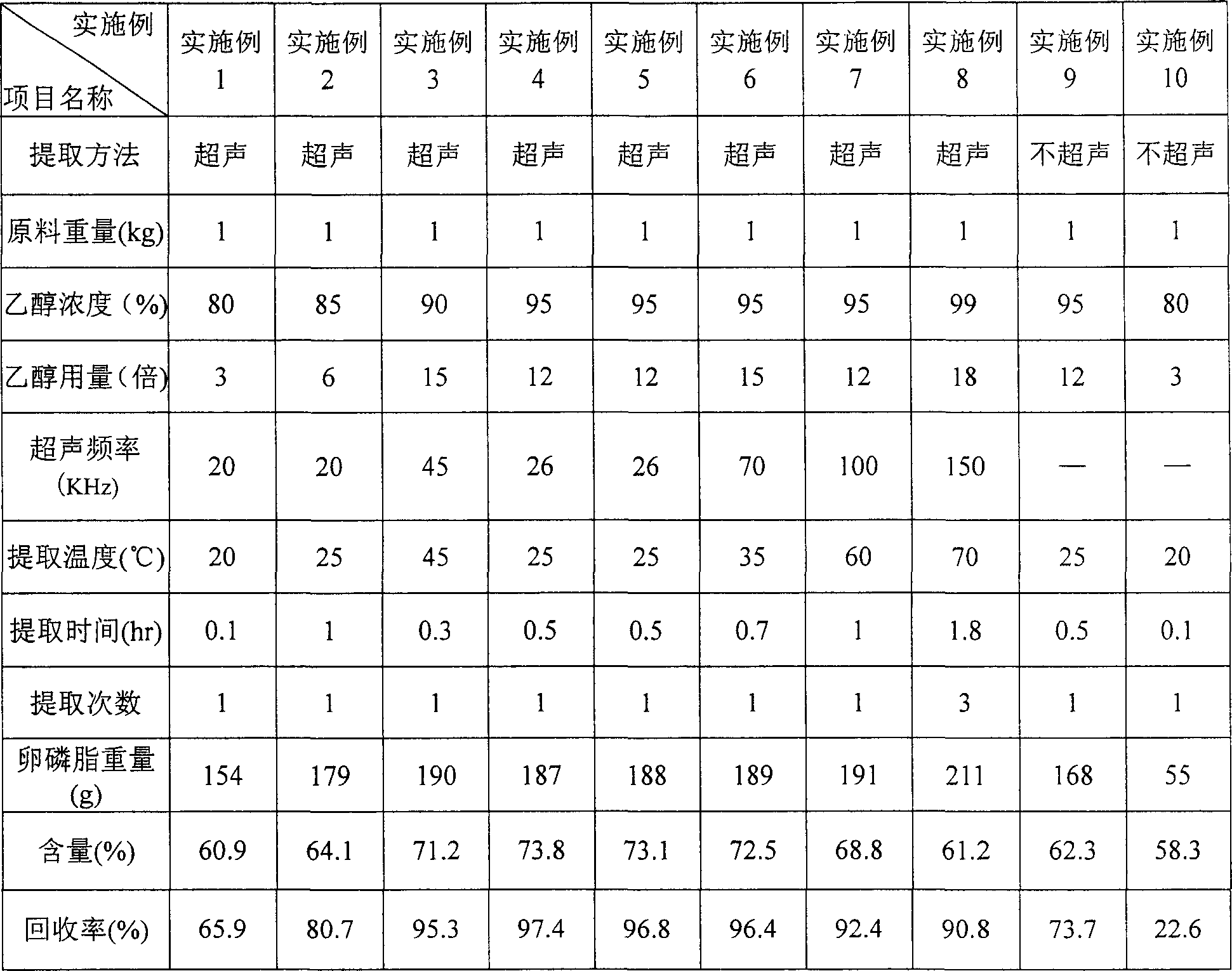

Embodiment 1

[0020] Weigh 1 kg of egg yolk powder, place it in a cleaning ultrasonic extraction container, add 3 L of 80% ethanol solution, set the ultrasonic frequency to 20KHz, ultrasonic time to 0.1 hr, and ultrasonic extraction temperature to 20°C. Ultrasonic extraction is performed once in a stirring state, and the material liquid extracted by ultrasonic is filtered to collect the clear liquid. Concentrate the supernatant liquid under reduced pressure at a temperature of 40°C to 45°C and a vacuum of -0.085MPa to -0.095MPa to a thick paste, recover the solvent, and place the obtained paste at a temperature of 45°C to 50°C and a vacuum of Dry under reduced pressure under the condition of -0.085MPa~-0.095MPa to obtain 154g of light yellow egg yolk lecithin, the content of lecithin determined by HPLC is 60.9%, and the recovery rate is 65.9%.

Embodiment 2

[0022] The ultrasonic equipment, raw materials and operation process used in Example 2 are the same as in Example 1, except that the ultrasonic extraction solvent is 6L of 85% ethanol solution, the ultrasonic extraction temperature is 25° C., and the ultrasonic extraction time is 1 hr. 179g of light yellow egg yolk lecithin was prepared under the process conditions, the content of lecithin was 64.1%, and the recovery rate was 80.7%.

Embodiment 3

[0024] The ultrasonic equipment used in the present embodiment, raw material and operating process are the same as embodiment 1, and the difference is that the relevant ultrasonic enhanced extraction process parameters are adjusted as follows: the added solvent is 15L of 90% ethanol solution, ultrasonic frequency 45KHz, ultrasonic extraction temperature The temperature is 45°C, and the extraction time is 0.3hr. The weight of the egg yolk lecithin product prepared by this method is 190g, the lecithin content is 71.2%, and the recovery rate is 95.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com