Ground pumping and mining coal seam gas well reformation method based on recurrence frequency impact waves

A coalbed methane well, repetition frequency technology, applied in mining equipment, earthwork drilling, gas discharge, etc., can solve the problems of coalbed methane wells without gas production, no effect, coal seam damage, etc., to achieve the ability to inhibit resorption, accelerate desorption, release The effect of coal seam clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

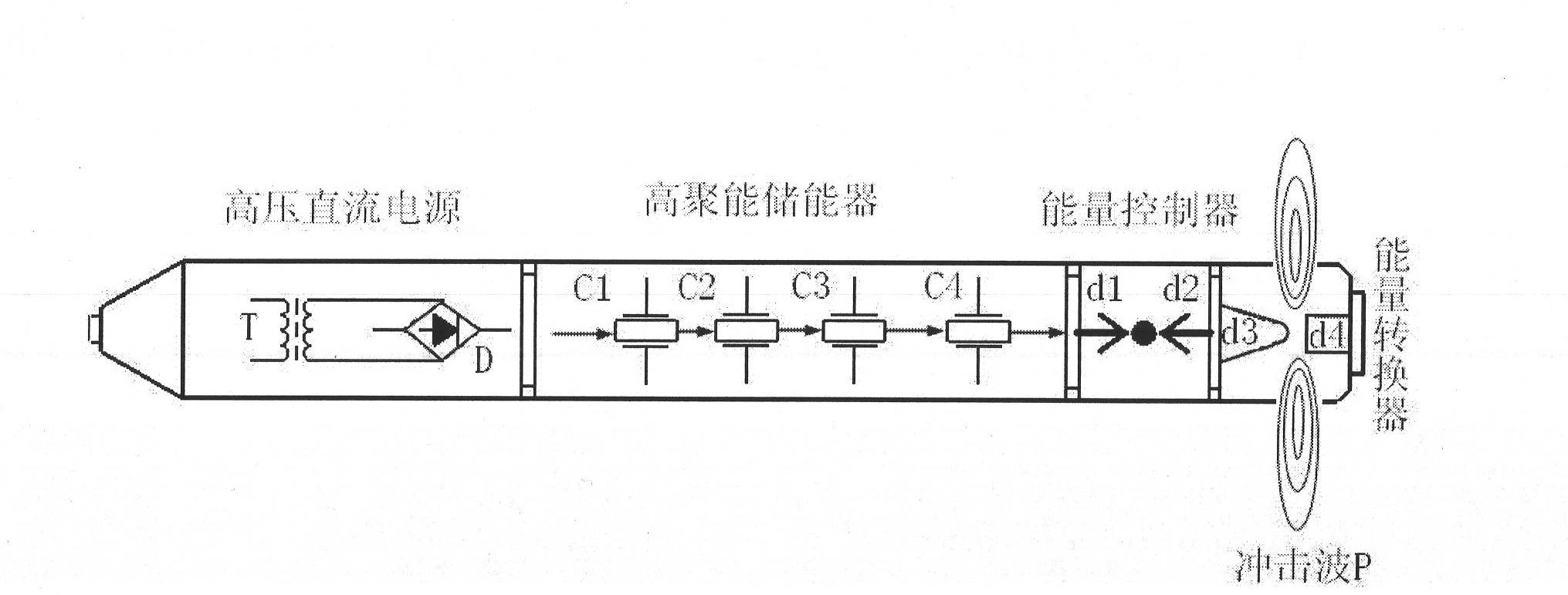

[0033] Before operation, it is first necessary to collect the relevant data of the coalbed methane wells to be operated, and analyze the reasons for production reduction based on the collected data such as coal and rock properties, coal seam physical properties, well formation methods, production and transformation history, and block production status; adjust high-energy and high-power The circuit parameters and working voltage of the electric pulse device, the amplitude, pulse width and repetition frequency of the design shock wave, and the underground equipment of the electric pulse device are used to perform repetition frequency operations on the coal seam.

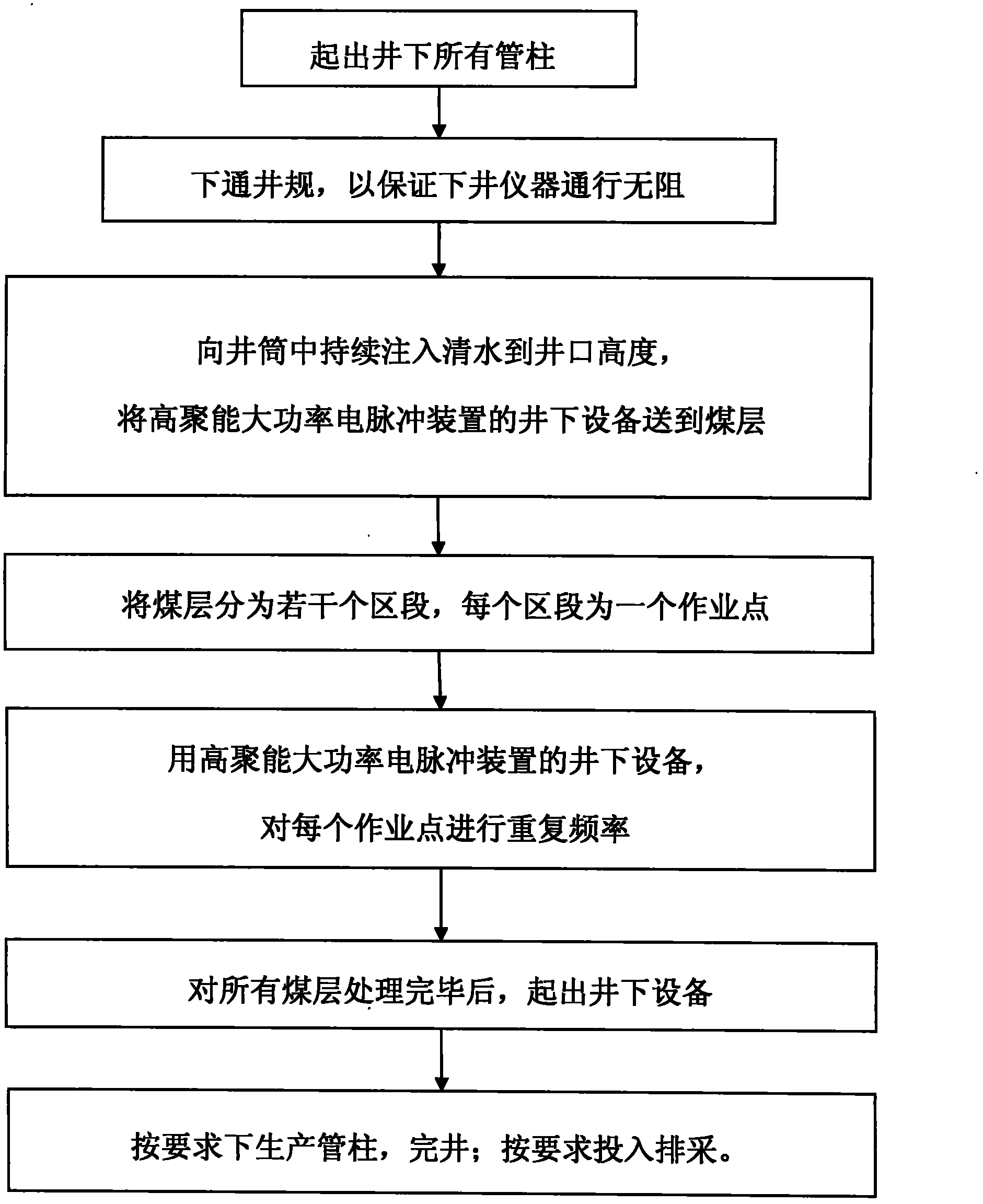

[0034] refer to figure 1 , the working process of the present invention is as follows

[0035] Step 1: Pull out all pipe strings downhole.

[0036] Before operation, lift out all the water pumps, water pipes, and suction rods in the wellbore, so that the downhole equipment of the electric pulse device can go downhole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com