Method for mining coalbed methane through coalbed burning assisted fracture forming

A technology for coalbed methane and coalbed methane wells, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of easy sand plugging, difficult construction, reservoir damage, etc. Fracturing fluid contamination and the effect of avoiding compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

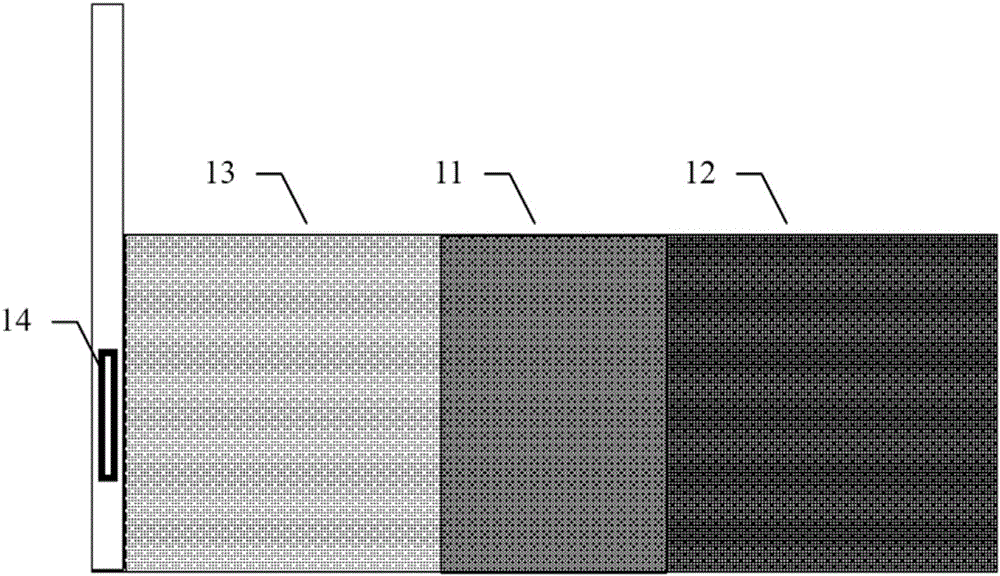

[0052] Example 1. Coalbed methane reservoir combustion reformation

[0053] 1) For selected CBM wells, the depth is 1128.4-1136.8m, the thickness is 5.6m, and the gas content is 15.31-19.36m 3 / t, the gas saturation is 71-89%, almost no gas is produced in the initial test, and nitrogen (N 2 ) (can also inject carbon dioxide (CO 2 )) gas pushes the coalbed methane near the wellbore to a depth of about 5m (equivalent to 25,000m under ground conditions) 3 ), for the purpose of isolating the injected air and the coalbed methane in the later stage, avoiding the risk of explosion caused by the direct contact between the injected air and the coalbed methane.

[0054] 2) Lower the electric heating igniter into the bottom of the well, inject air to ignite, the ignition temperature is guaranteed to be above 500℃, the maximum temperature is 525℃, and the initial injection speed is about 5000m 3 / d, the ignition time is 4 days, continue to inject air after turning off the igniter, and ...

Embodiment 2

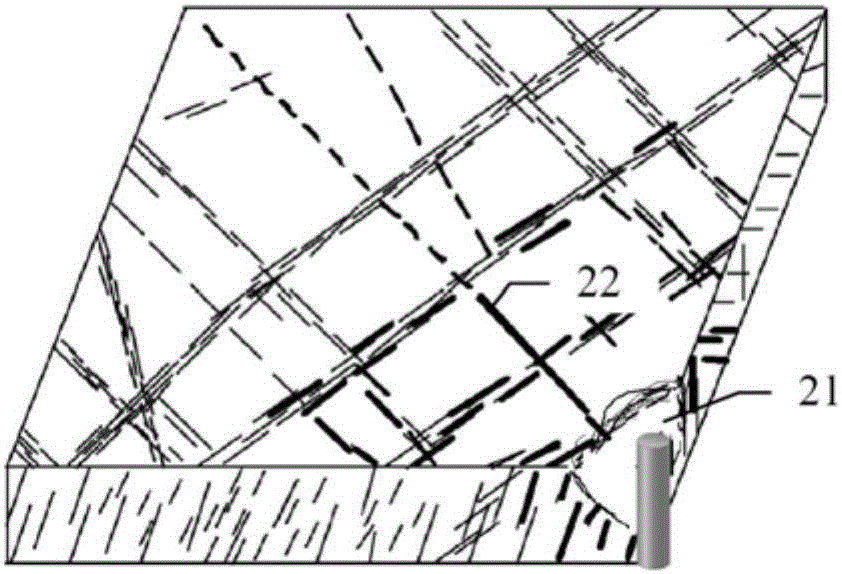

[0059] Example 2. Fracturing + Coalbed Gas Reservoir Fire Combination Reform

[0060] 1) For the selected CBM well, the depth is 606.6-609.6m, the thickness is 3m, and the gas content is 16-20m 3 / t, the gas saturation is 73%-93%. First, high-energy gas fracturing is used to generate multiple fractures.

[0061] 2) Run the electric heating igniter into the bottom of the well, inject air to ignite, the ignition temperature is guaranteed to be above 500℃, the highest temperature is 543℃, and the initial injection speed is about 8000m 3 / d, the ignition time is 5 days, turn off the igniter, continue to inject air, in order to generate more micro-cracks, increase the ventilation volume by 20000m in the later stage 3 / d air injection, accumulative air injection 40×10 4 m 3 , ignite the coal seam in the near wellbore area, and finally form the cave completion effect in the near wellbore area, relieve the pollution in the near wellbore area, and improve the seepage capacity in the...

Embodiment 3

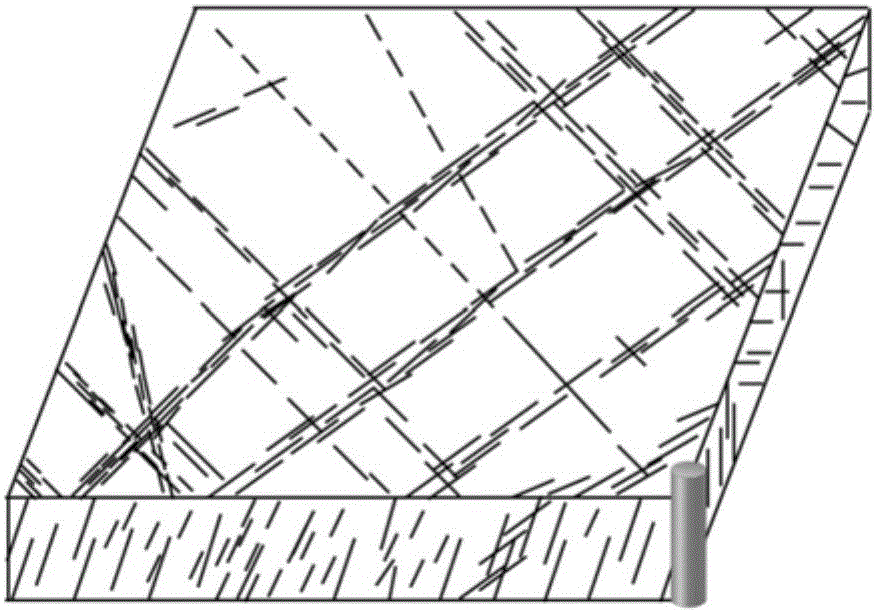

[0066] Example 3. Horizontal well in coalbed methane reservoir + combustion reformation

[0067] 1) For the selected CBM horizontal wells, the length of the horizontal well section is 500m 3 , the depth of the coalbed methane reservoir is 514.2-520.6m, the thickness is 5.4m, and the gas content is 16-26m 3 / t, gas saturation 90-98.9%, first inject a certain amount of nitrogen (N 2 ) gas pushes the coalbed methane near the wellbore to a depth of about 5m (equivalent to 60,000m under ground conditions) 3 ), for the purpose of isolating the injected air and the coalbed methane in the later stage, avoiding the risk of explosion caused by the direct contact between the injected air and the coalbed methane.

[0068] 2) Run the electric heating igniter into the bottom of the well, inject air to ignite, the ignition time is 40 days, the ignition temperature is guaranteed to be above 500℃, the maximum temperature is 532℃, and the initial injection speed is about 12000m 3 / d, the ign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com