Double-draining chemical modifier and application thereof

A chemical modifier and modification technology, applied in chemical instruments and methods, production fluids, drilling compositions, etc., can solve the problems of chaotic flow resistance, low water-flooding recovery rate, and obstruction of crude oil flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

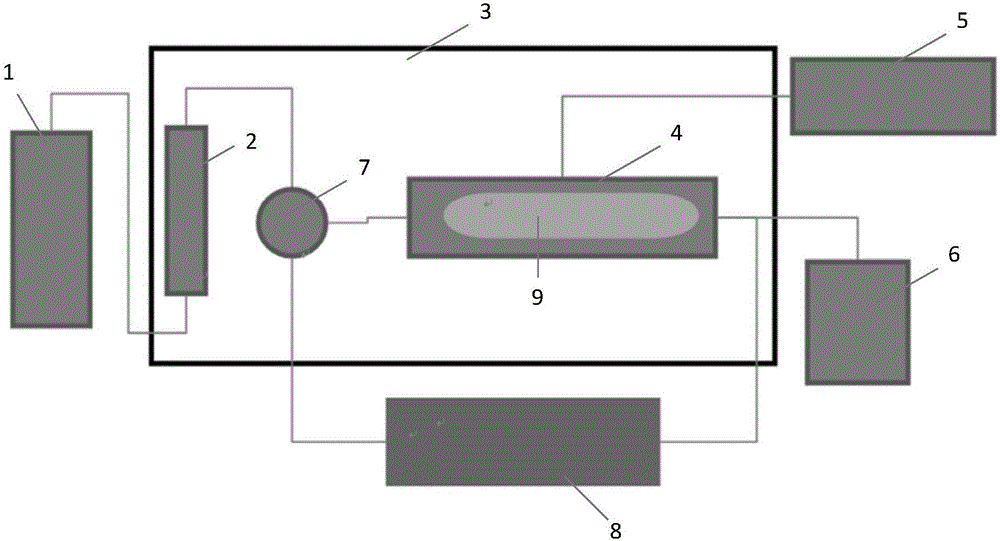

Method used

Image

Examples

preparation example Construction

[0023] According to the present invention, the modified nano-SiO 2 The preparation method preferably comprises the following steps:

[0024] γ-(methacryloyloxy)propyltrimethoxysilane, second organic solvent, nano-SiO 2 Mix well, filter and dry at high temperature.

[0025] Preferably, the concentration of the γ-(methacryloyloxy)propyltrimethoxysilane in the second organic solvent is 1-2mol / L; the γ-(methacryloyloxy)propyltrimethoxysilane Oxysilane and nano-SiO 2 The weight ratio is 2-5:1; the second organic solvent is at least one of acetone, butanone, pentanone and hexanone, more preferably acetone.

[0026] The uniform mixing conditions are, for example, stirring, ultrasonication, and the like.

[0027] The conditions for the high-temperature drying may include: the temperature is 180-200° C., and the time is 4-6 hours.

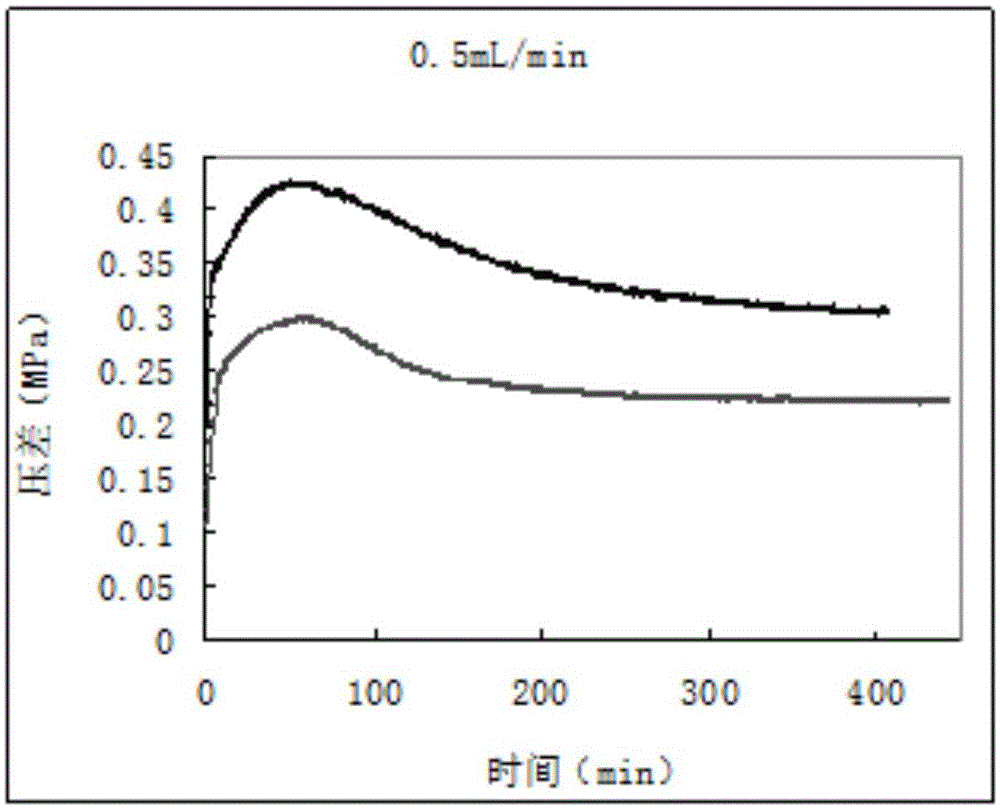

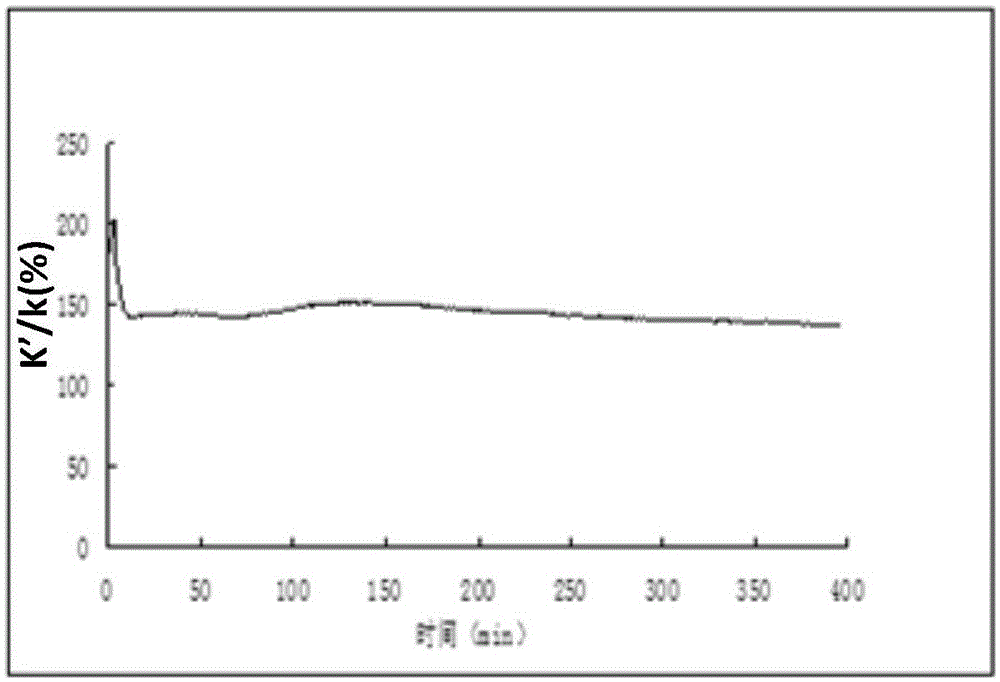

[0028] The amphiphobic chemical modifier of the invention can be used to improve the liquid-phase seepage capacity of rock cores, thereby increasing t...

Embodiment 1

[0034] Take 4.5g of γ-(methacryloyloxy)propyltrimethoxysilane (AH-570) and add it to the acetone solution, the concentration of AH-570 is 1.5mol / L, add 1.5g of nano-SiO 2 (particle size 30nm), stir well, ultrasonically disperse evenly, filter, dry in a high-temperature oven at 200°C for 4 hours, take it out and cool it for later use. in N 2 Under protection, take 3.6g of 4-perfluoro(2-isopropyl-1,3-dimethyl-1-butenyl)oxystyrene (FOSt) into a three-necked flask, add butanone, and then add 1.2 g modified nano-SiO 2 Carry out surface grafting, stir for 1 hour, heat up to 60°C, add azobisisobutyronitrile, and keep warm at 60°C for 36 hours to realize the purpose of introducing low surface energy substances and changing the surface microstructure, and obtain a chemically modified surface with hydrophobic and oleophobic properties. Agent A.

Embodiment 2

[0036] Take 3g of γ-(methacryloyloxy)propyltrimethoxysilane (AH-570) and add it to the acetone solution, the concentration of AH-570 is 1mol / L, add 1.5g of nano-SiO 2 (particle size 40nm), stir well, ultrasonically disperse evenly, filter, dry in a high-temperature oven at 180°C for 6 hours, take it out and cool it for later use. in N 2 Under protection, take 2.4g of 4-perfluoro(2-isopropyl-1,3-dimethyl-1-butenyl)oxystyrene (FOSt) into a three-necked flask, add butanone, and then add 1.2 g modified nano-SiO 2Carry out surface grafting, stir for 1.5h, heat up to 70°C, add azobisisobutyronitrile, and keep warm at 70°C for 42h to realize the purpose of introducing low surface energy substances and changing the surface microstructure, and obtain a hydrophobic and oleophobic Chemical Modifier B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com