Method for separating isoprene by combined rectification

A technology for the separation of isoprene and rectification, applied in the direction of distillation purification/separation, organic chemistry, etc., can solve the problems of reducing the use value of dicyclopentadiene, affecting the purity of dicyclopentadiene, and affecting the purity of isoprene , to achieve the effect of improving the use value, reducing the difficulty of design and operation, and preventing the loss of self-aggregation or copolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

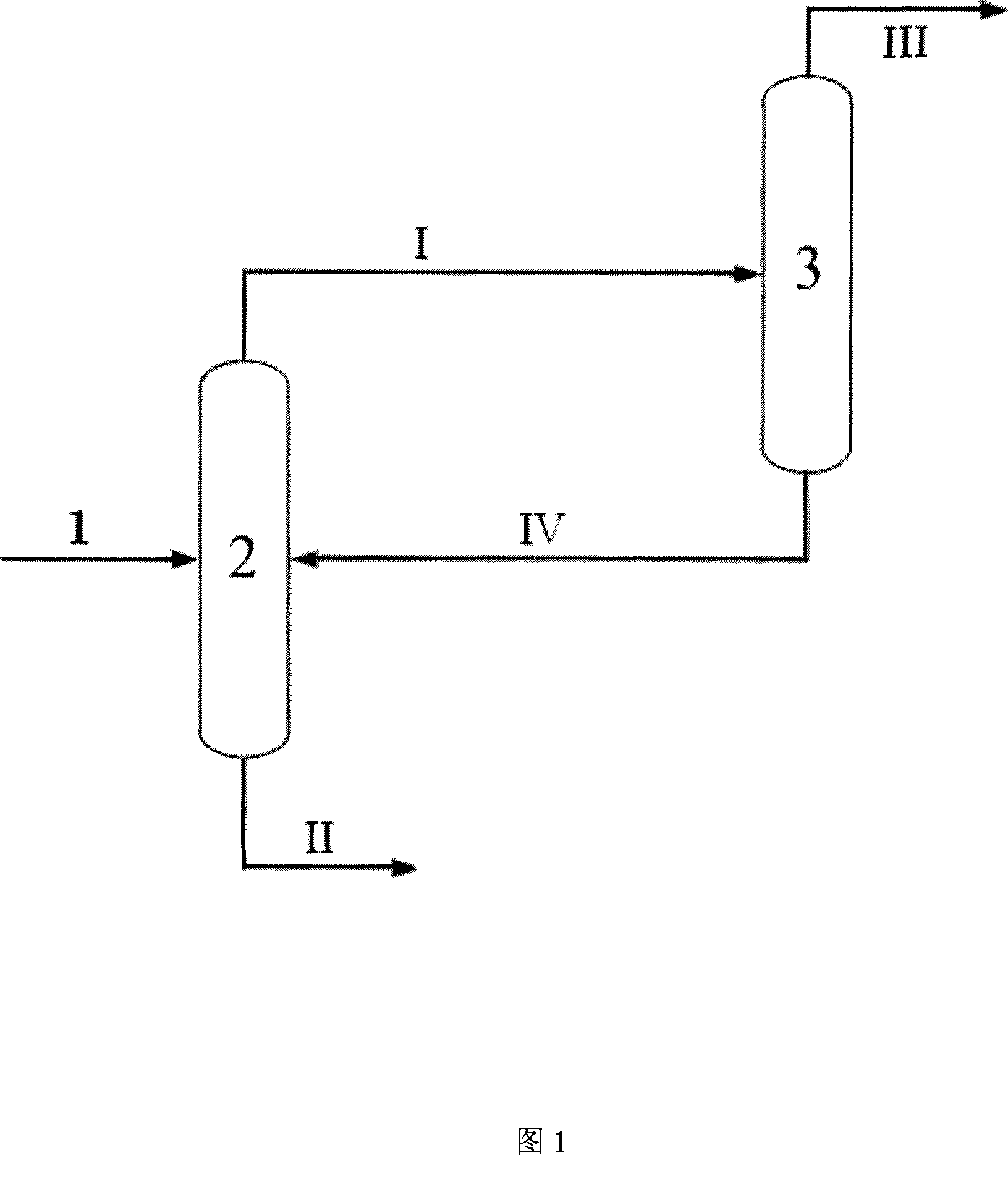

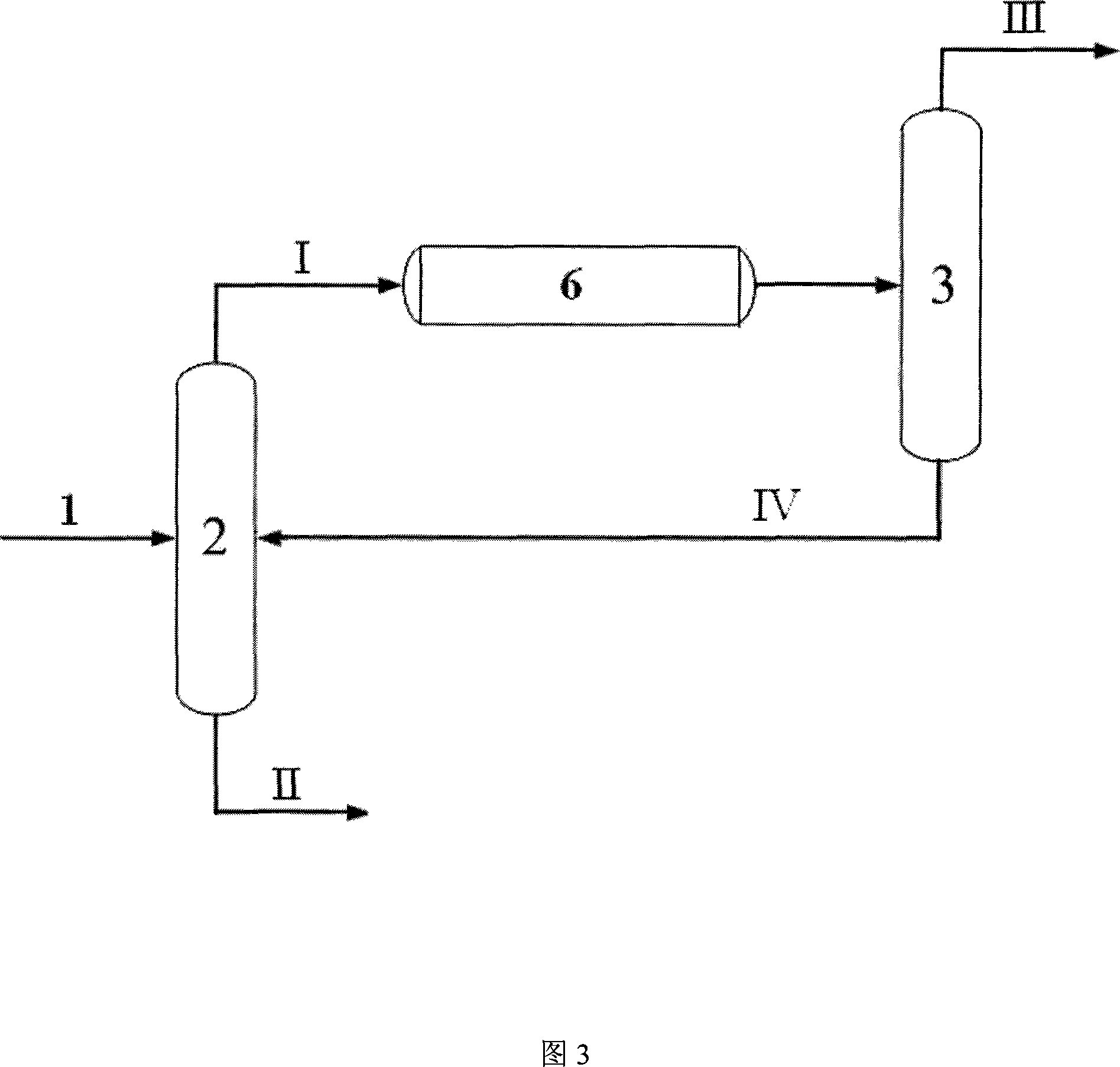

[0030] According to the process flow shown in Figure 1, the carbon five material 1 enters the isoprene separation tower 2 from the 52nd tray, and the separation at the top of the tower obtains the stream I rich in isoprene, and the separation at the bottom of the tower obtains the stream I rich in cyclopentadiene The logistics II enters the follow-up process. The feed temperature of the isoprene separation tower 2 is 76°C, the number of trays is 100, the temperature of the tower bottom is 70°C, the temperature of the top of the tower is 44°C, the pressure of the top of the tower is 0.04MPa, the pressure of the bottom of the tower is 0.11MPa, and the reflux The ratio is 15. The reboiler heat load per ton of C5 feed is 0.83MW.

[0031] The stream I enters the cyclopentadiene recovery tower 3 from the 49th tray, and a small amount of cyclopentadiene in the isoprene-rich stream is separated and recovered. The overhead stream III enters the subsequent isoprene refining process, a...

Embodiment 2

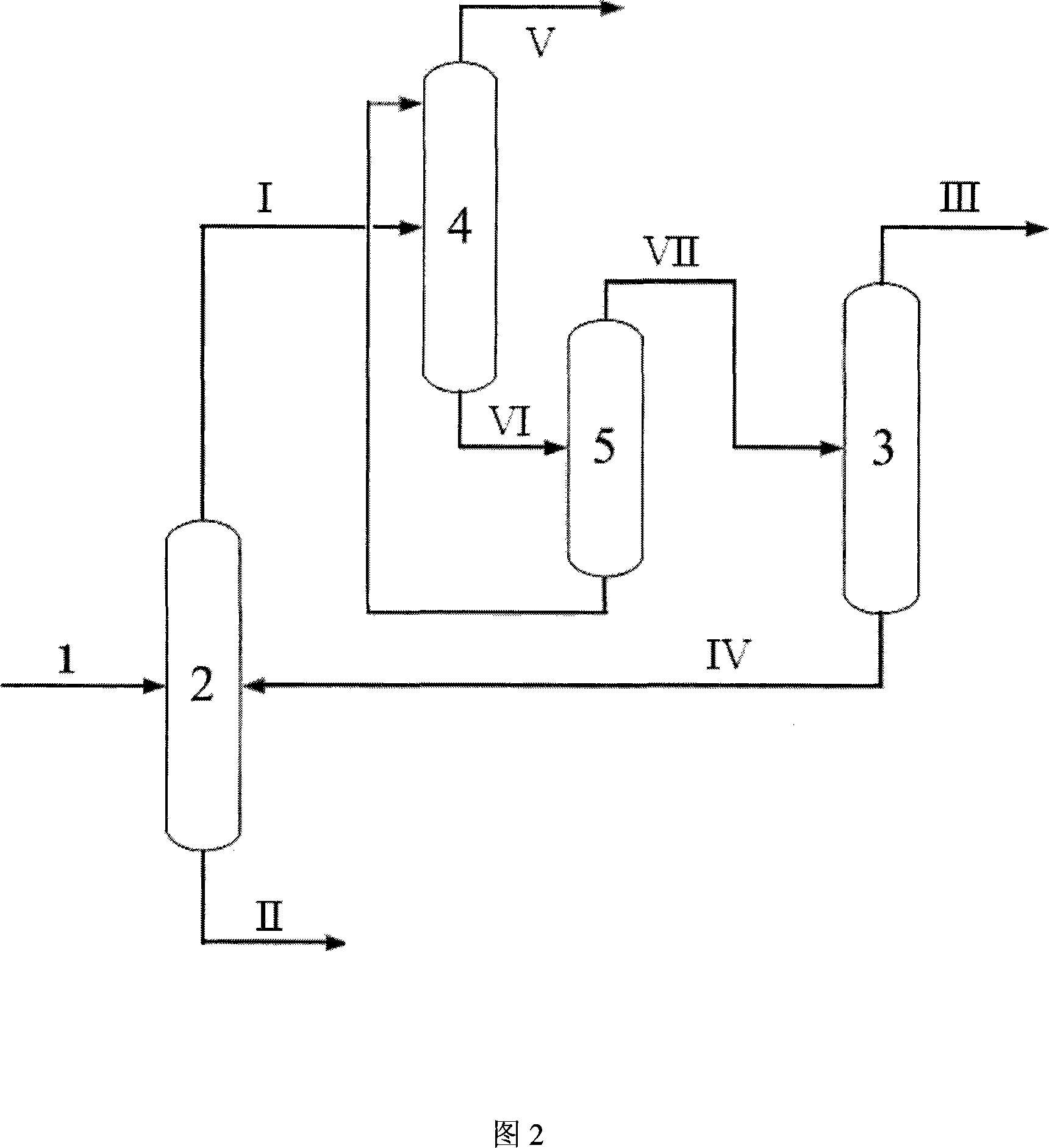

[0036] According to the process flow shown in Figure 2, the carbon five material 1 enters the isoprene separation tower 2 from the 55th tray, and the polymerization inhibitor o-nitrophenol is added from the 10th tray, and the isoprene-rich Diene stream I is separated in the tower to obtain stream II rich in cyclopentadiene, which enters the subsequent process. The feed temperature of the isoprene separation tower 2 is 76°C, the number of trays is 110, the temperature of the tower bottom is 79°C, the temperature of the top of the tower is 55°C, the pressure of the top of the tower is 0.09MPa, the pressure of the bottom of the tower is 0.17MPa, and the reflux The ratio is 11. The reboiler heat load per ton of C5 feed is 0.63MW.

[0037] Stream I enters the extractive distillation tower 4 from the 73rd tray, and contacts with the dimethylformamide solvent that enters from the 6th tray at the top of the tower to carry out extractive distillation, and the column reactor obtains a ...

Embodiment 3

[0044] Press the technological process of [embodiment 2], only the solvent of extracting and rectifying is acetonitrile, the polymerization inhibitor of extracting and rectifying is nitrogen methyl pyrrolidone, and the polymerization inhibitor and cyclopentadiene in the isoprene separating tower 2 reclaim The polymerization inhibitor in the tower is diethylhydroxylamine.

[0045] The operating conditions of each unit are shown in Table 3, and the weight percentage composition of raw materials and components of each unit is shown in Table 4.

[0046] table 3

[0047] operating conditions

Isoprene separation tower 2

Extractive distillation column 4

Stripper 5

Cyclopentadiene recovery tower 3

Feed temperature (°C)

75

-

-

-

The number of trays at the feed (blocks)

66

46

30

52

Total number of plates (blocks)

130

90

56

80

Tower kettle temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com