Preparation method of magnetic lignosulfonate adsorbing material

A technology of lignosulfonate and adsorption material, which is applied in the field of preparation of magnetic lignosulfonate adsorption material, can solve the problems of uneven distribution of magnetic particles, easy agglomeration, etc., and achieves wide application, mild conditions and wide source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the magnetic lignosulfonate adsorption material proposed by the present invention comprises the following steps:

[0024] (1) dissolving lignosulfonate in water to form lignosulfonate aqueous solution, so that the mass volume concentration of lignosulfonate aqueous solution is 1~10g / L;

[0025] (2) Ferrous iron salt and ferric salt are added in the solution of above-mentioned step (1) successively and stirred, obtain the first solution that mixes uniformly, in the first solution, Fe 3+ The molar concentration of Fe is 0.01~0.04mol / L, Fe 2+ with Fe 3+ The molar ratio is 1:2~1:1;

[0026] (3) make the first solution of above-mentioned step (2) react under ultrasonic condition, ultrasonic frequency is 40kHz, and temperature is 20~40 ℃, in ultrasonic process, add alkaline precipitation agent drop by drop, make the pH value of solution greater than 10 , reacted for 40 to 90 minutes to obtain the reactant;

[0027] (4) After the reaction is over,...

Embodiment 1

[0034] 0.5g sodium lignosulfonate was dissolved in 100mL deionized water, 0.4865g FeSO 4 ·7H 2 O was added to the sodium lignosulfonate solution and stirred until completely dissolved, then 0.5406g FeCl 3 ·6H 2 O was added to the solution and stirred until completely dissolved. The solution was placed under ultrasonic conditions, and 4 mol / L sodium hydroxide aqueous solution was added dropwise to adjust the pH value to 13, and reacted at room temperature for 1 h. The reacted solution is subjected to solid-liquid separation under the action of a magnetic field, the upper liquid is poured off, the solid phase is washed with deionized water until neutral, and finally the solid phase is freeze-dried to obtain a magnetic lignosulfonate adsorption material.

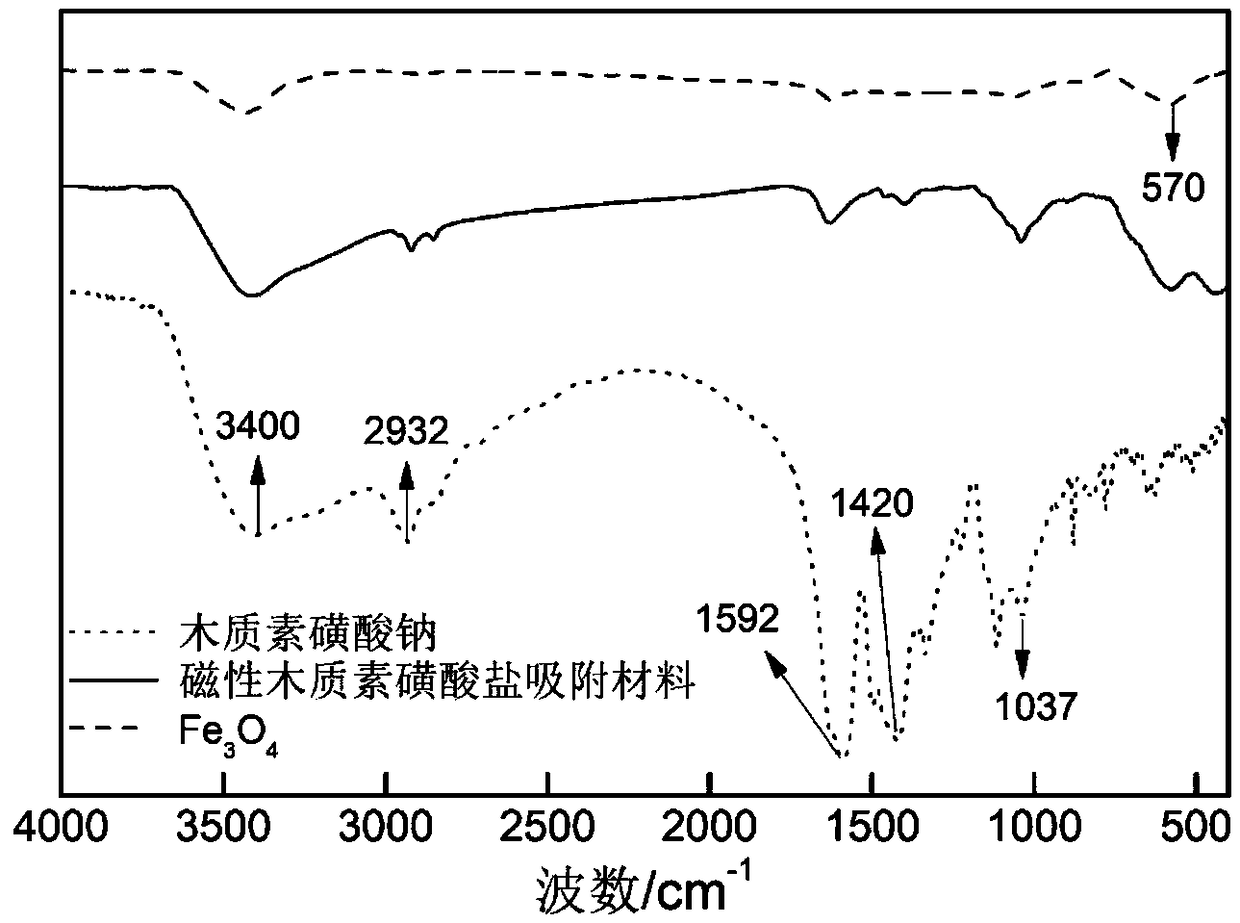

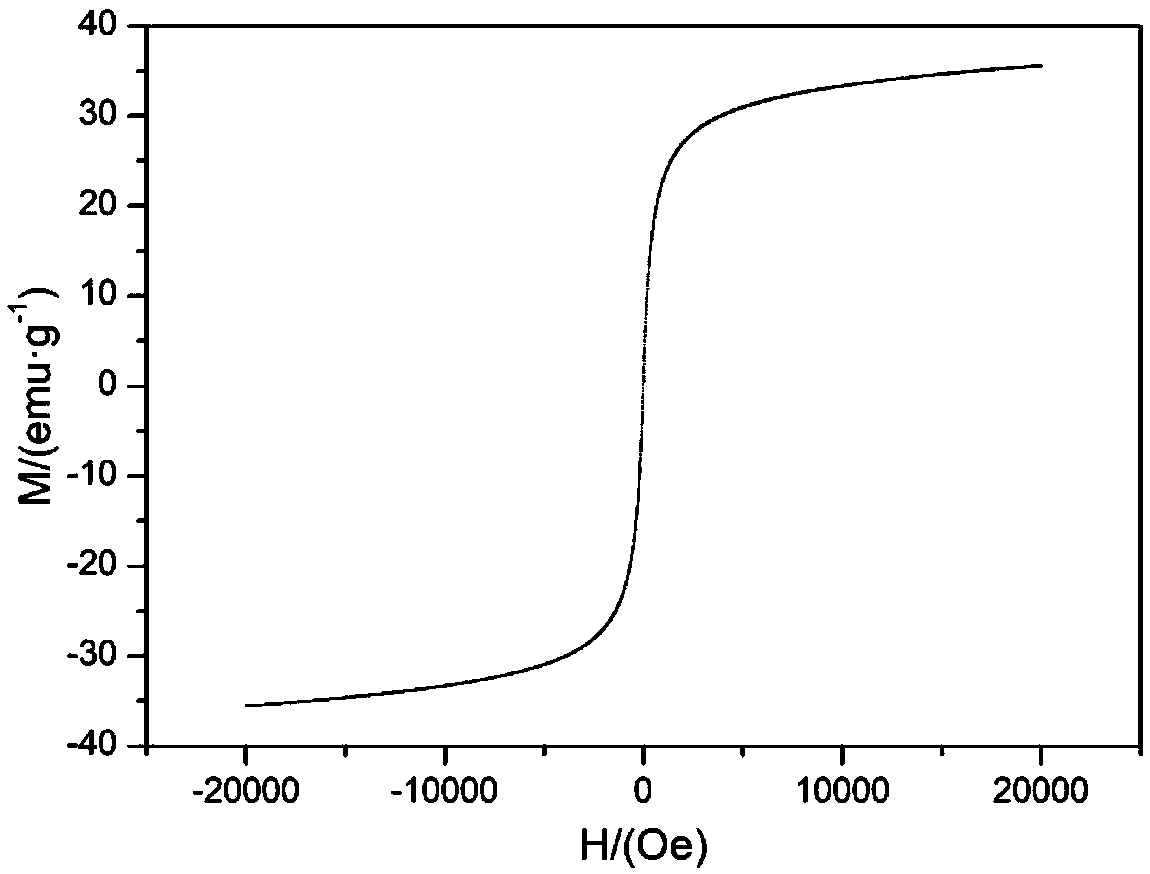

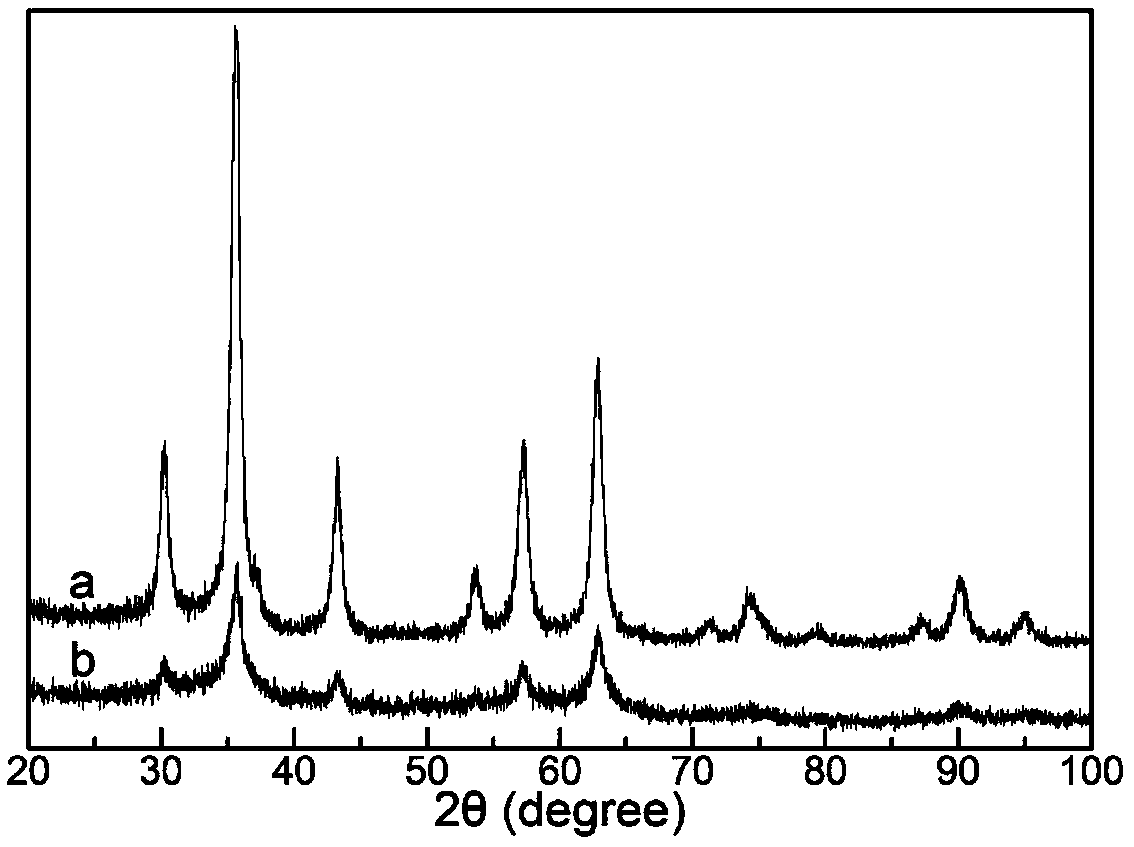

[0035] Structural characterization of magnetic lignosulfonate adsorption materials: FT-IR, VSM and XRD were used to analyze the prepared magnetic lignosulfonate adsorption materials.

[0036] Such as figure 1 Shown are sod...

Embodiment 2

[0038]0.5g sodium lignosulfonate was dissolved in 100mL deionized water, 0.4170g FeSO 4 ·7H 2 O was added to the sodium lignosulfonate solution and stirred until completely dissolved, then 0.5406g FeCl 3 ·6H 2 O was added to the solution and stirred until completely dissolved. The solution was placed under ultrasonic conditions, and 4 mol / L sodium hydroxide aqueous solution was added dropwise to adjust the pH value to 13, and reacted at room temperature for 1 h. The reacted solution is subjected to solid-liquid separation under the action of a magnetic field, the upper liquid is poured off, the solid phase is washed with deionized water until neutral, and finally the solid phase is freeze-dried to obtain a magnetic lignosulfonate adsorption material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com