Preparation method for organosilicone acrylate

A technology of acrylate and silicone, which is applied in the field of silicone acrylate preparation, can solve the problems of product impurity, single acrylate group, difficulty in meeting the requirements of defoamer dispersibility and defoaming, etc. To achieve the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

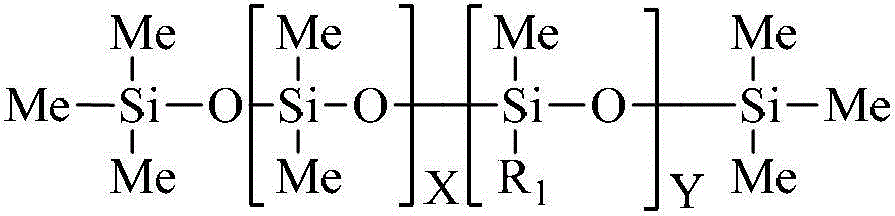

[0028] The embodiment of the present invention provides a method for preparing silicone acrylate, the preparation method comprising:

[0029] Step 1 Preparation of epoxy hydrocarbon-based silicone: In the presence of inert gas, catalyst, polymerization inhibitor and epoxy stabilizer, low-hydrogen silicone oil and unsaturated epoxy compound are reacted at 60-100°C for 0.5-2 hours, and then distilled to obtain Epoxy hydrocarbon-based silicone, wherein the molar ratio of the silicon-hydrogen bond of the low-hydrogen silicone oil to the carbon-carbon double bond of the unsaturated epoxy compound is 1:(1~2);

[0030] Step 2 Preparation of silicone acrylate: in the presence of air, esterification reaction catalyst, polymerization inhibitor and antioxidant, react the epoxy hydrocarbon-based silicone with unsaturated carboxylic acid at 60-100°C for 10-25 hours , to obtain silicone acrylate, wherein the molar ratio of the epoxy group of the epoxy alkyl silicone to the carboxyl group of...

Embodiment 1

[0050] The embodiment of the present invention provides a method for preparing silicone acrylate, the method comprising:

[0051] Add 12g of high hydrogen-containing silicone oil (hydrogen content 1.5%, viscosity 30cst), 2g of hexamethyldisiloxane (MM), 90g of octamethyldisiloxane (MM) into a 500ml three-necked reaction flask equipped with mechanical stirring, condenser and thermometer Tetrasiloxane (D4) and 2g concentrated sulfuric acid, control the temperature of the oil bath at 40°C, and stir for 6h. Pour the mixed solution into a separatory funnel, let it stand for half an hour, separate and remove the yellow acid solution at the bottom layer, pour the upper layer liquid into a reaction bottle, and neutralize it with 3.4 g of sodium bicarbonate powder. Distill at 110°C and 1.3kPa to remove low-boiling substances, and finally filter to obtain a colorless and transparent low-hydrogen silicone oil with a relative molecular weight of 12,000.

[0052] Weigh 55.87g of the above...

Embodiment 2

[0057] The embodiment of the present invention provides a method for preparing silicone acrylate, the method comprising:

[0058] Add 18g of high hydrogen-containing silicone oil (hydrogen content 1.0%, viscosity 50cst), 4.6gMM, 77.4gD4 and 10g of strongly acidic macroporous cationic resin to a 500ml three-necked reaction flask equipped with mechanical stirring, condenser, and thermometer, and control the oil bath The temperature was at 80°C and stirred for 8h. After filtration, take the filtrate, and distill off low boiling point substances at 110°C and 1.3kPa to obtain a colorless and transparent low-hydrogen silicone oil with a relative molecular weight of 8,000.

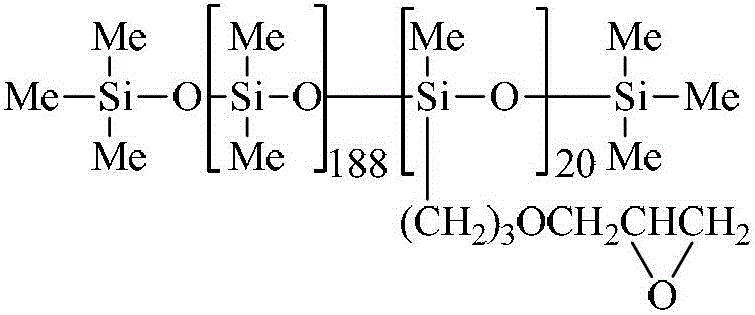

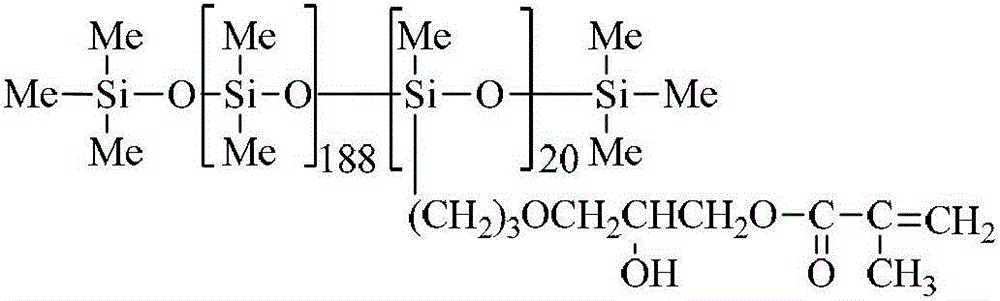

[0059] The preparation steps of epoxy hydrocarbon-based silicone and silicone acrylate are the same as in Example 1. The product is a brownish-yellow transparent liquid, and its infrared absorption spectrum confirms that it is silicone acrylate, and its molecular structure is as follows:

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com