Polymerization inhibitor suitable for vinyl aromatic compound

A vinyl aromatic and polymerization inhibitor technology, applied in the field of polymerization inhibitors, can solve the problems of high requirements for polymerization inhibitors, and achieve the effects of high polymerization inhibition efficiency, low cost, and extended running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

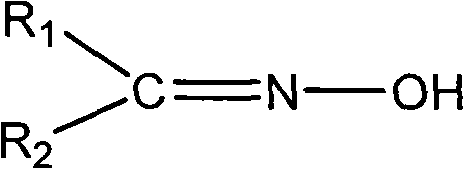

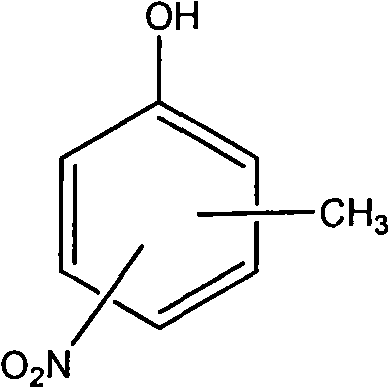

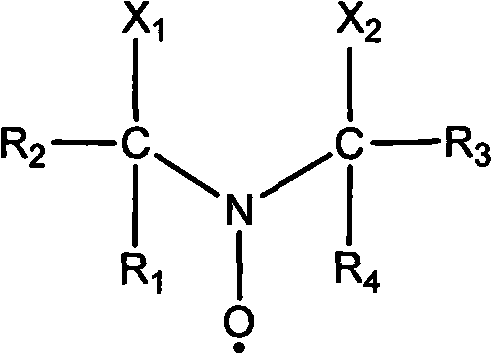

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the composite polymerization inhibitor of the present invention is: mix and dissolve the substances in the A component, the B component and the C component according to the mass ratio of 1:0.5~10:1~10 in the organic solvent, at room temperature After fully stirring and dissolving evenly, it can be added to the monomer.

[0030]In industrial applications, the polymerization inhibitor can be added to the monomer in any common way, for example, it can be added in a countercurrent (relatively newly added monomer) mode at an appropriate position, and each component can also be added with the newly added monomer. The monomers are fed together to ensure efficient distribution of the inhibitor component in the monomer. Since the polymerization inhibitor is gradually consumed in the monomer rectification process, the polymerization inhibitor is appropriately supplemented in the rectification process to ensure that there is enough polymerization inhibito...

Embodiment 1

[0033] Each polymerization inhibitor was dissolved in styrene according to the formula ratio of 0.012 part SA, 0.05 part DNBP and 0.015 part OH-TEMPO (based on 100 parts of St) to prepare a polymerization inhibitor solution, and then added to the purified styrene , carry out the reaction under normal pressure at 120°C, take an appropriate amount of the reaction solution at regular intervals to measure the amount of polymer generated by the refractive index method, and the results of the reaction for 7 hours are shown in Table 1.

Embodiment 2

[0035] Each polymerization inhibitor was tested for the polymerization inhibition effect according to the method in Example 1 according to 0.013 part of SA, 0.05 part of DNBP and 0.015 part of TEMPO (based on 100 parts of St).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com