Purification method of propionaldehyde

A purification method and technology of propionaldehyde, applied in the separation/purification of carbonyl compounds, organic chemistry and other directions, can solve the problems of harsh conditions, reduced content of propionaldehyde, cumbersome operation process, etc., and achieve the effect of high polymerization inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

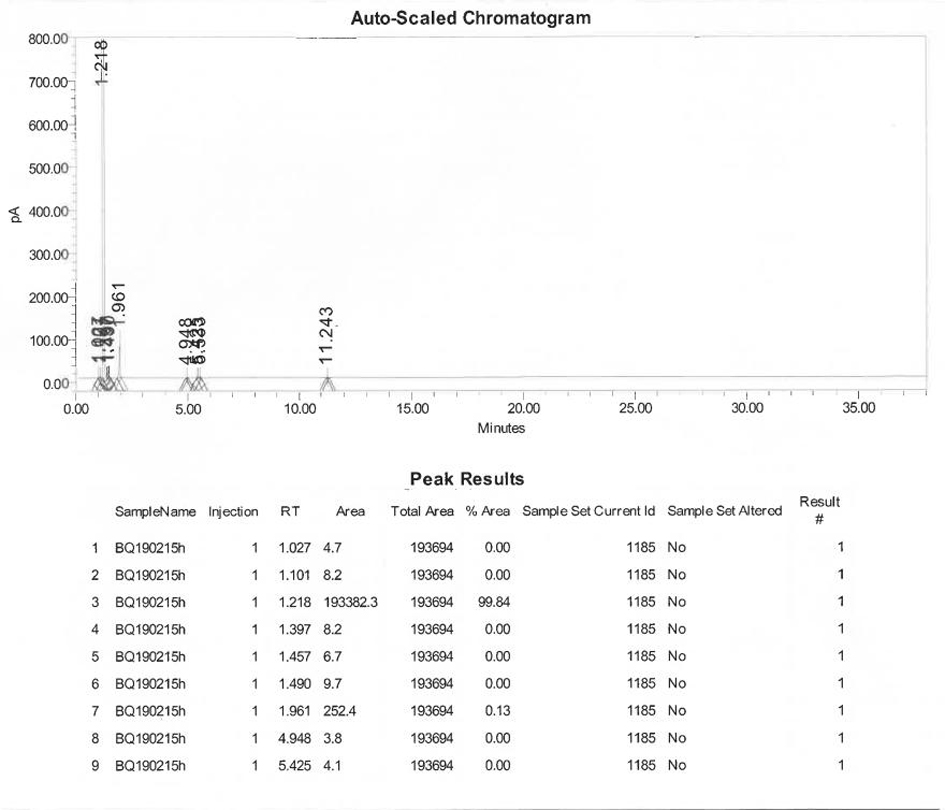

[0026] Weigh 500g of 88% low-content propionaldehyde, add 2g of ammonium acetate, turn on the heating and raise the external temperature to 90°C, collect the effluent, control the top temperature at 47-50°C, stop collecting when about 350g is collected, and pour into the effluent Add 10g of potassium carbonate to the mixture, stir for 30 minutes, filter, collect the filtrate, and collect 342g of high-content propionaldehyde. Gas chromatography content is 99.84%, see GC spectrum figure 1 .

Embodiment 2

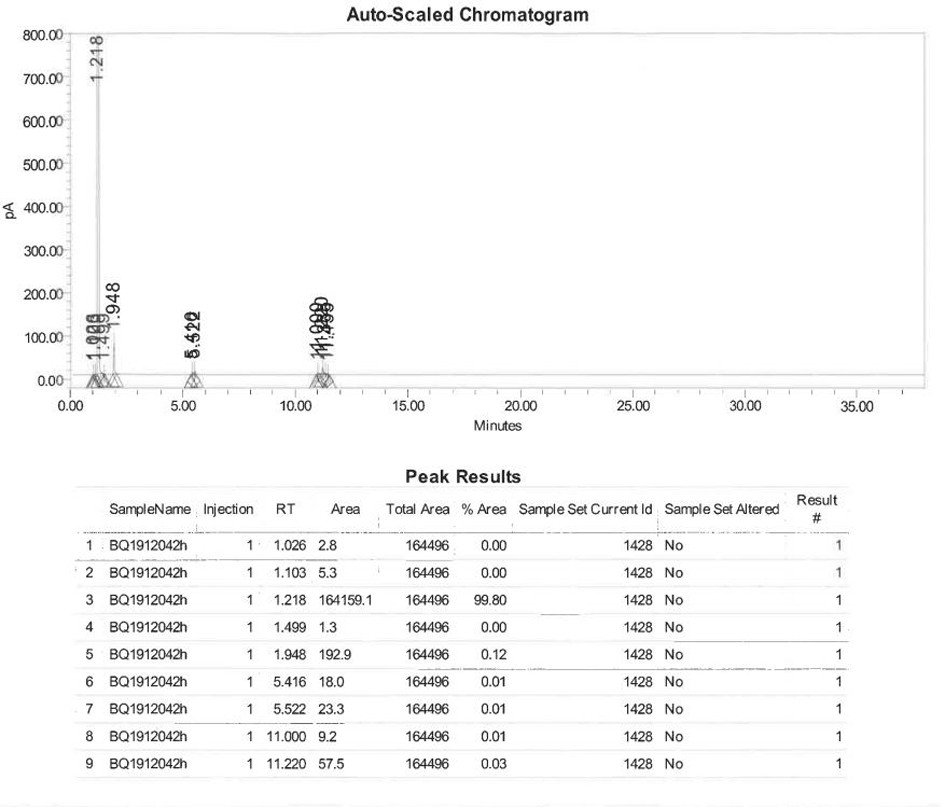

[0028] Weigh 5kg of propionaldehyde with 92% low content, add 10g of triamine citrate, turn on the heating and raise the external temperature to 120°C, collect the effluent, control the top temperature at 47-53°C, stop collecting when about 4.7kg is collected, and pour to Add 100 g of sodium carbonate to the effluent, stir for 1 hour, filter, collect the filtrate, and collect 4.6 kg of high-content propionaldehyde. Gas chromatography content is 99.80%, see GC spectrum figure 2 .

Embodiment 3

[0030] Weigh 5kg of 95% low-content propionaldehyde, add 10g of triamine citrate, turn on the heating and raise the external temperature to 120°C, collect the effluent, control the top temperature at 47-53°C, stop collecting when about 4.7kg is collected, and pour to Add 100 g of sodium carbonate to the effluent, stir for 1 hour, filter, collect the filtrate, and collect 4.7 kg of high-content propionaldehyde. The gas chromatography content is 99.82%.

[0031] The content and moisture of embodiment 1-3 gained high-content propionaldehyde are shown in Table 1

[0032] Table 1

[0033] project Example 1 Example 2 Example 3 Propionaldehyde content 99.84% 99.80% 99.82% moisture 0.04% 0.07% 0.05%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com