Rectification polymerization inhibitor for aromatic olefin monomer, preparation method and application method thereof

A technology of aryl olefin and polymerization inhibitor, applied in the field of rectification polymerization inhibitor, can solve the problems of polymer blocking fillers and pipes, poor polymerization inhibition effect, and difficulty in precipitation, so as to reduce the polymerization rate, reduce the cost of auxiliary agents, and reduce toxicity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

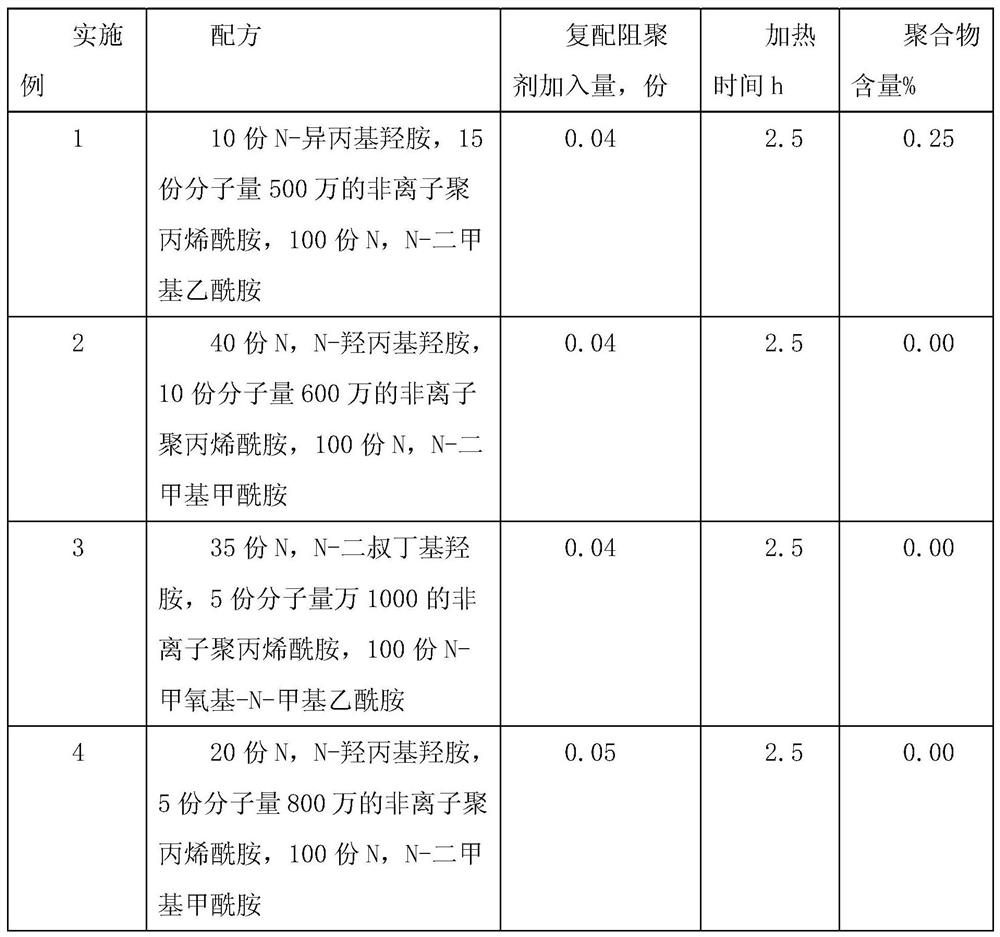

[0037] Weigh the three components of A, B and C of the present invention according to a certain proportion, add them together with styrene in the four-necked flask, add a condenser above the four-necked flask, and replace the air in the system with nitrogen for 10 Minutes to reduce the oxygen content in the flask, then seal the system, place the four-neck flask in a constant temperature heater to heat, keep the temperature at 125°C for a certain period of time, and take samples to analyze the polystyrene content in styrene.

[0038] Determination of the amount of polymer produced by gravimetric method: taking advantage of the property that the polymer is insoluble in methanol, add enough dry methanol to the sample to completely precipitate the polymer, then filter, dry, weigh, and keep the weight constant to obtain The mass of polymer produced. The experimental results are shown in Table 1. The distribution ratio of each component of the polymerization inhibitor in the table i...

Embodiment 10-14

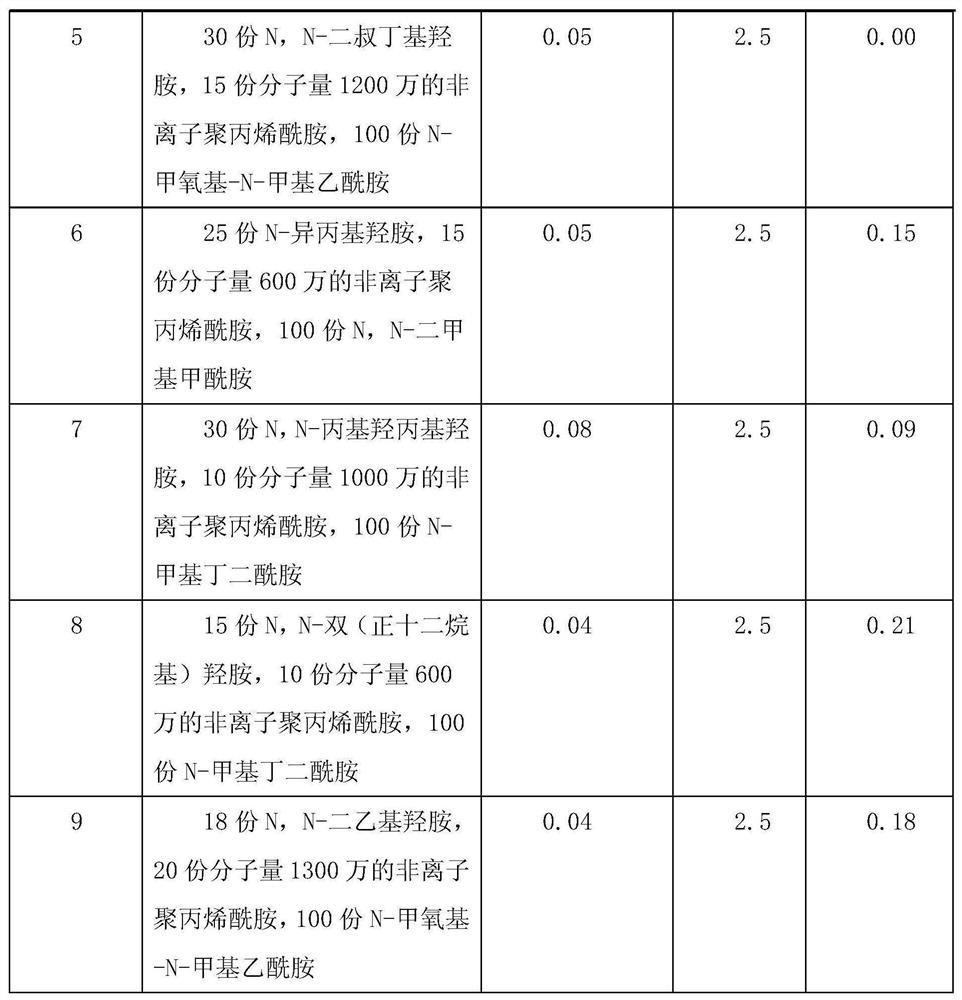

[0044] Prepare a polymerization inhibitor according to the process described in Example 1, and add it to styrene, keep the temperature at 125°C for 2.5 hours, sample and analyze the content of polystyrene in styrene, wherein the compounded polymerization inhibitor is: 27 parts N, N-di-tert-butylhydroxylamine, 9 parts of nonionic polyacrylamide with a molecular weight of 12 million, and 100 parts of N-methoxy-N-methylacetamide. Taking the mass of styrene as the basis of 100 parts, the polymerization inhibition effect varies with the amount of different polymerization inhibitors as shown in Table 2.

[0045] The polymerization inhibitor add-on of table 2 embodiment 10-14 and its polymerization inhibition effect

[0046]

[0047]

[0048] It can be seen that with the increase of the amount of polymerization inhibitor, the effect of polymerization inhibition is obviously improved. In practical application, it can be considered comprehensively from the amount of polymerizati...

Embodiment 15-16

[0050] The polymerization inhibitor was prepared according to the process described in Example 1, wherein the raw materials and their formulations are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com