Preparation method of viscosity-reducing type polycarboxylate water reducer

A technology of viscous polycarboxylic acid and water reducing agent, applied in the field of preparation of viscosity reducing polycarboxylate water reducing agent, can solve the problems of slow flow speed, long construction period, high viscosity, etc., to increase early strength, increase The effect of hydrophilic-lipophilic balance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

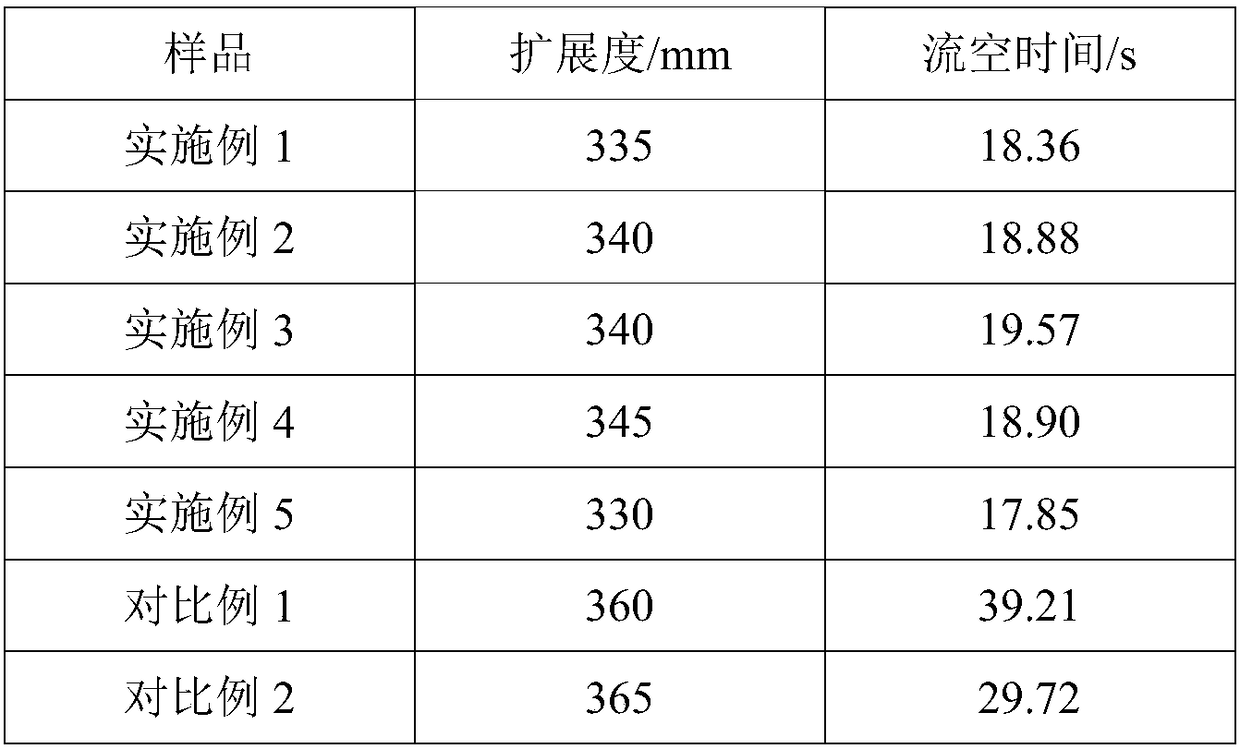

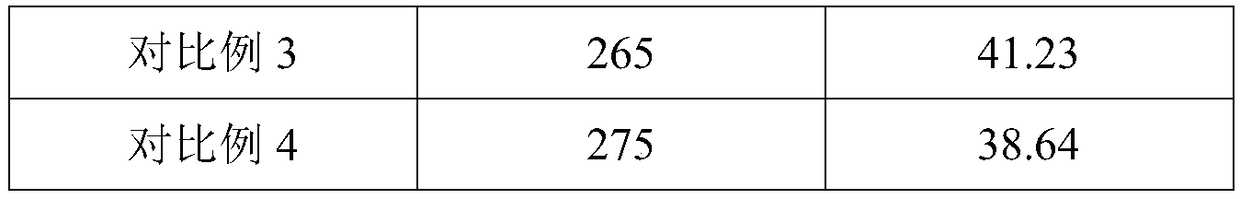

Examples

Embodiment 1

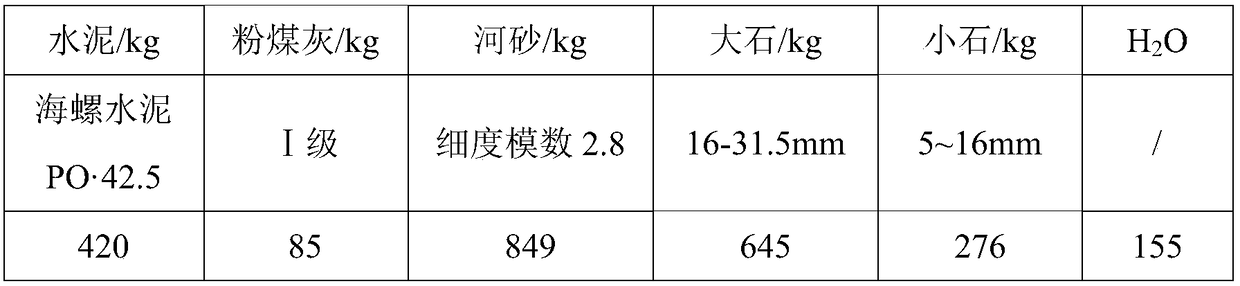

[0045] Example 1: Take 300g of isopentenol polyoxyethylene ether with a molecular weight of 2400 and 360g of tap water into the bottom of the tank, turn on the stirring, stir and dissolve at 20°C, continue to add 27g of fumaric acid diethanolamide phosphate to the bottom of the tank , After the bottom material is dissolved into mixed solution A, add 1.2g of 30% hydrogen peroxide solution and stir and mix. After 5 minutes, add dropwise mixed solution B consisting of 36.77g maleic anhydride, 1.5g mercaptopropionic acid and 50g water. , And mixed solution C composed of 0.3g ascorbic acid and 100g water, mixed solution B dripping time 2.5h, mixed solution C dripping time 3h, after all the solutions are dripped, warm up to 25℃ and keep for 1.5h, react After finishing, slowly add 32% sodium hydroxide solution to neutralize the product pH to 7.

Embodiment 2

[0046] Example 2: Take 300g of isopentenol polyoxyethylene ether with a molecular weight of 2400 and 360g of tap water into the bottom of the tank, turn on the stirring, stir and dissolve at 25°C, continue to add 6.23g of fumaric acid diethanolamide phosphoric acid to the bottom of the tank After the bottom material is dissolved into mixed solution A, add 9g of sodium hypophosphite and stir to mix, then add 3.84g of ammonium persulfate and stir to mix, 10 minutes later, 14g of maleic anhydride and 75g of maleic anhydride are simultaneously added dropwise Mixed solution B composed of monomethyl ester and 50g water, and mixed solution C composed of 3.63g sodium formaldehyde sulfoxylate and 100g water, mixed solution B dripping time 3h, mixed solution C dripping time 3.5h, wait until all After all the solution was dripped, the temperature was raised to 30° C. and kept for 1 hour. After the reaction, 32% sodium hydroxide solution was slowly added to neutralize the pH of the product ...

Embodiment 3

[0047] Example 3: Take 300 g of isopentenol polyoxyethylene ether with a molecular weight of 2900 and 360 g of tap water into the bottom of the tank, turn on the stirring, stir and dissolve at 25°C, continue to add 15 g of fumaric acid diethanolamide phosphate to the bottom of the tank , After the bottom materials are dissolved into mixed solution A, add 3g ammonium persulfate and stir and mix. After 8 minutes, add dropwise a mixed solution consisting of 30g itaconic acid, 25g dimethyl itaconic acid, 2.5g thioglycolic acid and 50g water. B. And mixed solution C composed of 1.1g sodium formaldehyde sulfoxylate and 100g water, mixed solution B dripping time 3h, mixed solution C dripping time 3.5h, after all the solutions are dripped, the temperature is raised to 30 Keep the temperature at ℃ for 1h. After the reaction is over, slowly add 32% sodium hydroxide solution to neutralize the pH of the product to 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com