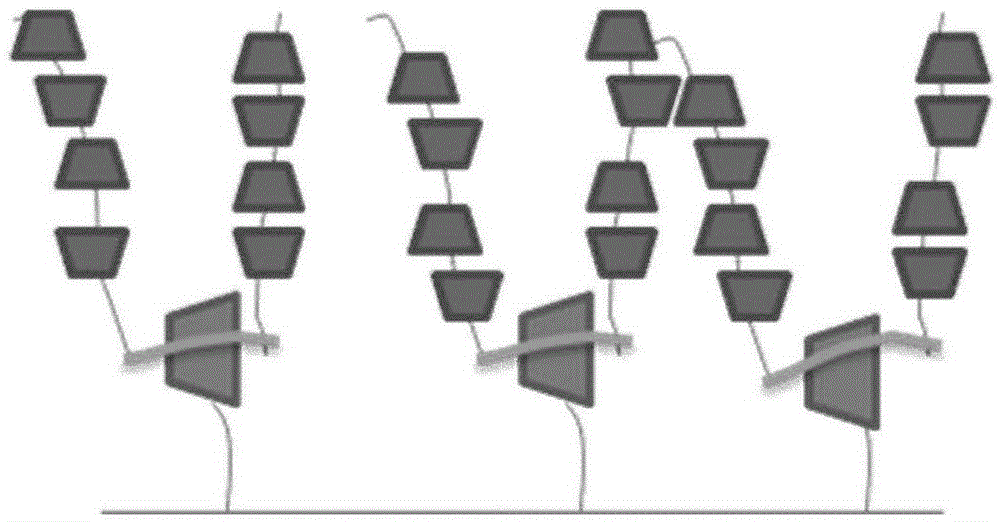

Preparation method of composite cyclodextrin hydrogel

A composite cyclodextrin and hydrogel technology, which is applied in the field of gel materials, can solve the problems of limited application and achieve the effect of wide adsorption range and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

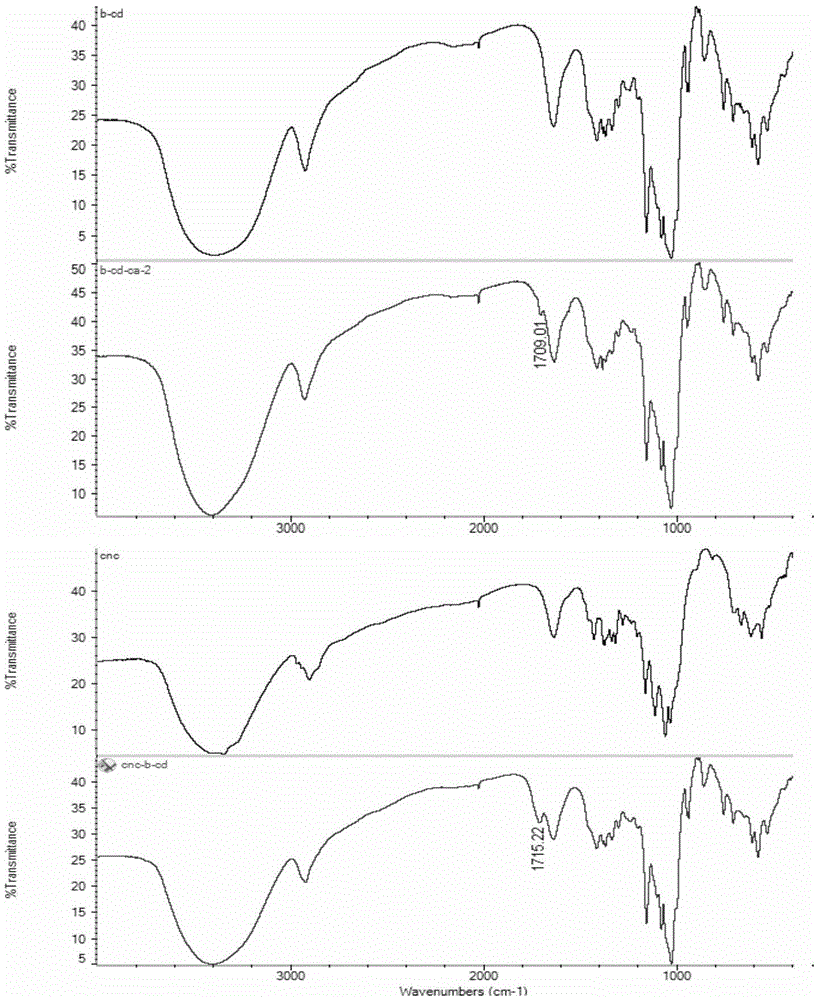

[0029] (1) Dissolve 11.35g of β-cyclodextrin, 4.2g of citric acid, and 1.06g of sodium hypophosphite in 6.81g of water, respectively, and put them in an oven at 100°C for 1.5h before taking them out. Extract with ethanol for 6h, add a small amount of water to dissolve, and then add acetone to make it precipitate. Filtration was repeated 3 times, and the obtained product was dried in an oven at 60°C. The product was characterized by a Fourier transform infrared spectrometer with 32 scans; the resolution was 4 cm-1; the scan range was 400-4000 cm-1.

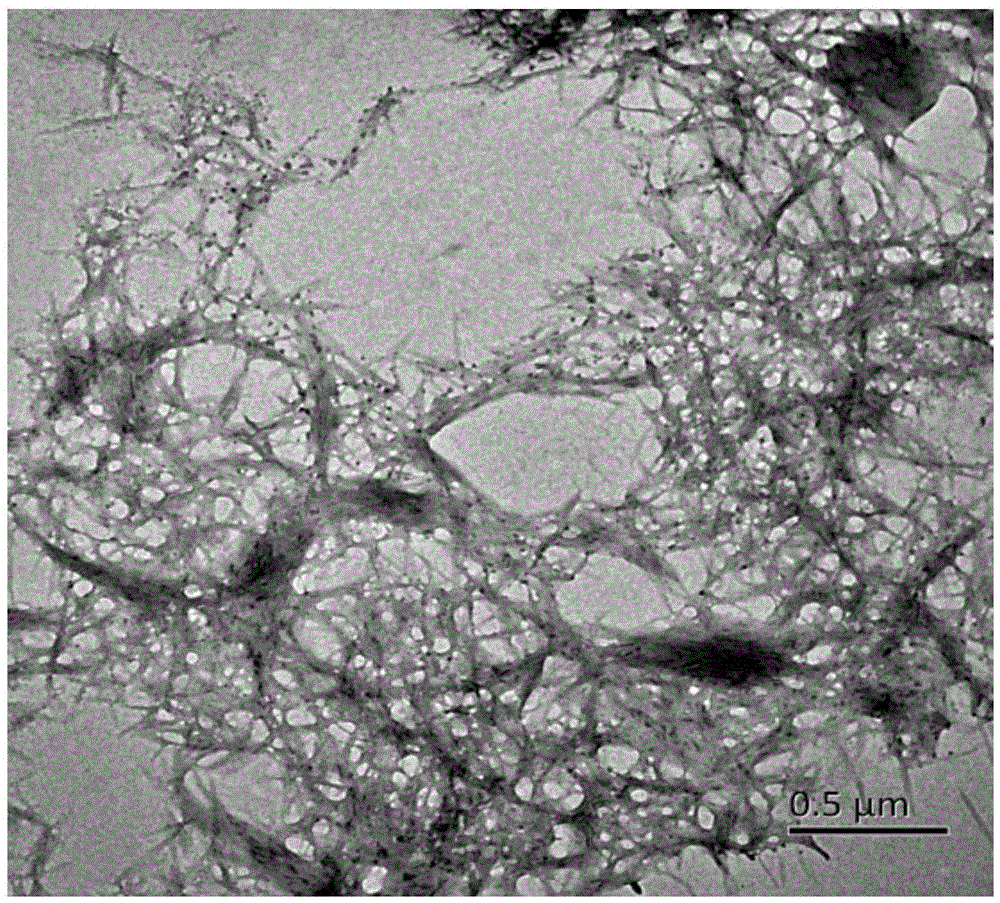

[0030] (2) Weigh 12.5g of absorbent cotton and add it to 250mL of 65% sulfuric acid solution to soak at room temperature for 30min, stir in a water bath at 45°C for 1h, add water to terminate the reaction, and centrifuge at 10,000rpm for 20min until the supernatant appears milky white, then transfer the product to a dialysis bag Dialyzed in medium for 5 days, freeze-dried, and the product was characterized by transmission electron ...

Embodiment 2

[0040] (1) Dissolve 11.35g of β-cyclodextrin, 4.2g of citric acid, and 1.06g of sodium hypophosphite in 6.81g of water, respectively, and put them in an oven at 100°C for 1.5h before taking them out. Extract with ethanol for 6h, add a small amount of water to dissolve, and then add acetone to make it precipitate. Dry in an oven at 60°C, and characterize the product with a Fourier transform infrared spectrometer, with 32 scans; a resolution of 4 cm-1; and a scan range of 400-4000 cm-1.

[0041] (2) Weigh 12.5g of absorbent cotton and add it to 250mL of 65% sulfuric acid solution to soak at room temperature for 30min, stir in a water bath at 45°C for 1h, add water to terminate the reaction, and centrifuge at 10,000rpm for 20min until the supernatant appears milky white, then transfer the product to a dialysis bag Dialyzed in medium for 5 days, freeze-dried, and the product was characterized by transmission electron microscope.

[0042](3) Dissolve 3 g of the product obtained in...

Embodiment 3

[0046] (1) Dissolve 11.35g of β-cyclodextrin, 4.2g of citric acid, and 1.06g of sodium hypophosphite in 6.81g of water, respectively, and put them in an oven at 100°C for 1.5h before taking them out. Extract with ethanol for 6h, add a small amount of water to dissolve, and then add acetone to make it precipitate. Filtration was repeated 3 times, and the obtained product was dried in an oven at 60°C. The product was characterized by a Fourier transform infrared spectrometer with 32 scans; the resolution was 4 cm-1; the scan range was 400-4000 cm-1.

[0047] (2) Weigh 12.5g of absorbent cotton and add it to 250mL of 65% sulfuric acid solution to soak at room temperature for 30min, stir in a water bath at 45°C for 1h, add water to terminate the reaction, and centrifuge at 10,000rpm for 20min until the supernatant appears milky white, then transfer the product to a dialysis bag Dialyzed in medium for 5 days, freeze-dried, and the product was characterized by transmission electron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com