Tetrabutyl tin preparation method

A technology of tetrabutyltin and anhydrous tin tetrachloride, applied in chemical instruments and methods, tin organic compounds, compounds of elements of Group 4/14 of the periodic table, etc., can solve problems such as spraying fire and eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

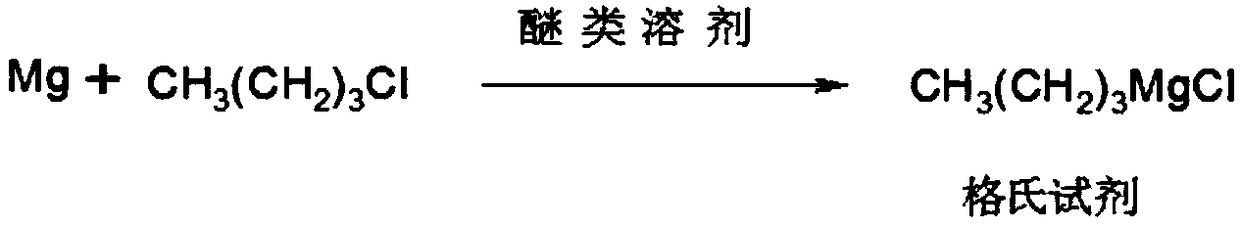

Method used

Image

Examples

Embodiment 1

[0014] Drop into 12.2 grams of magnesium powder (0.50mol) and 150 grams of 2-methyltetrahydrofuran in the flask of 500 milliliters, open and stir and be heated to reflux, add 7.5 grams of n-chlorobutane (0.08mol) and 0.5 grams of YF-017 catalyst The mixture, and then a mixture of 38.8 g of n-chlorobutane (0.42 mol) and 34.2 g of anhydrous tin tetrachloride (0.13 mol) was slowly added dropwise, and refluxed for 5 hours after the dropwise addition was completed. After cooling, 100 g of 10% hydrochloric acid was added, and the layers were allowed to stand. Emit the lower floor water phase, carry out atmospheric distillation to the organic phase, change the reduced pressure distillation after all solvents are evaporated, collect 148~150 ℃ of cuts (vacuum tightness is-650Pa), obtain 33.8 grams of products, tetrabutyltin content 96.5% ( GC), the yield was 77.87% (calculated as n-chlorobutane).

Embodiment 2

[0016] Drop into 12.2 gram magnesium powders (0.50mol) and 100 gram isopropyl ethers in the flask of 500 milliliters, open and stir and be heated to reflux, add the mixture of 7.5 gram n-chlorobutanes (0.08mol) and 0.5 gram YF-017 catalysts, Then, a mixed solution of 38.8 grams of n-chlorobutane (0.42 mol) and 34.2 grams of anhydrous tin tetrachloride (0.13 mol) was slowly added dropwise, and refluxed for 5 hours after the dropwise addition was completed. After cooling, 100 g of 10% hydrochloric acid was added, and the layers were allowed to stand. Emit the lower floor water phase, carry out atmospheric distillation to the organic phase, change the reduced pressure distillation after all solvents are steamed, collect 148~150 ℃ of cuts (vacuum tightness is-650Pa), obtain 32.5 grams of products, tetrabutyltin content 96.8% ( GC), the yield was 74.49% (calculated as n-butane chloride).

Embodiment 3

[0018] Drop into 12.2 gram of magnesium powders (0.53mol) and 150 gram of isopropyl ethers in the flask of 500 milliliters, open stirring and be heated to reflux, add the mixture of 7.5 gram of chlorobutane (0.08mol) and 1 gram of YF-017 catalyst, Then, a mixed solution of 38.8 grams of n-chlorobutane (0.42 mol) and 34.2 grams of anhydrous tin tetrachloride (0.13 mol) was slowly added dropwise, and refluxed for 5 hours after the dropwise addition was completed. After cooling, 100 g of 10% hydrochloric acid was added, and the layers were allowed to stand. Release the lower floor water phase, carry out normal pressure distillation to the organic phase, change the reduced pressure distillation after all solvents are evaporated, collect 148~150 ℃ of cuts (vacuum degree is-650Pa), obtain 33.1 grams of products, tetrabutyltin content 97.1% ( GC), the yield was 76.28% (calculated as n-chlorobutane).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com