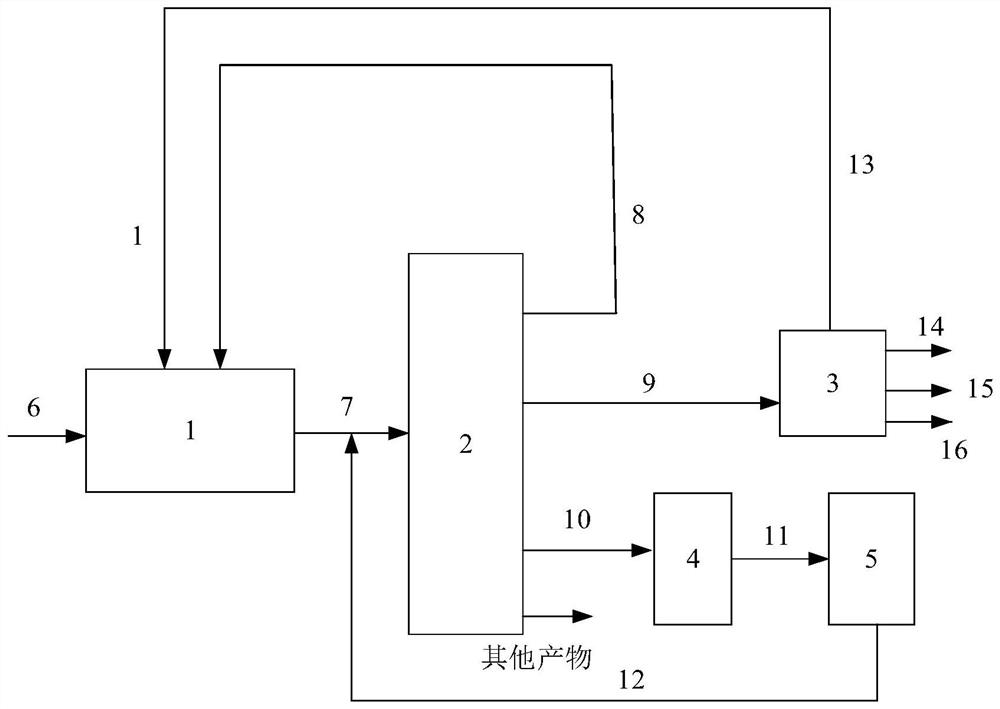

Method and system for treating catalytic cracking gasoline and catalytic cracking process and device for increasing yield of xylene

A catalytic cracking and catalytic cracking technology, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, hydrocarbon oil treatment products, etc., can solve the problems of high catalyst requirements, harsh reaction conditions, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

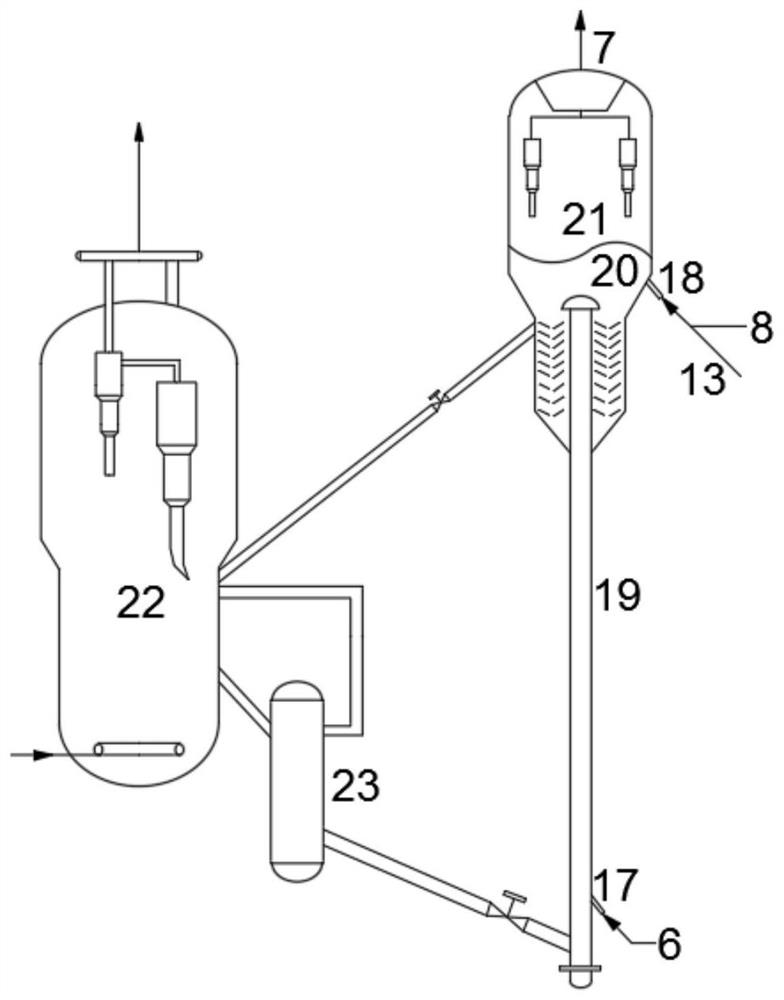

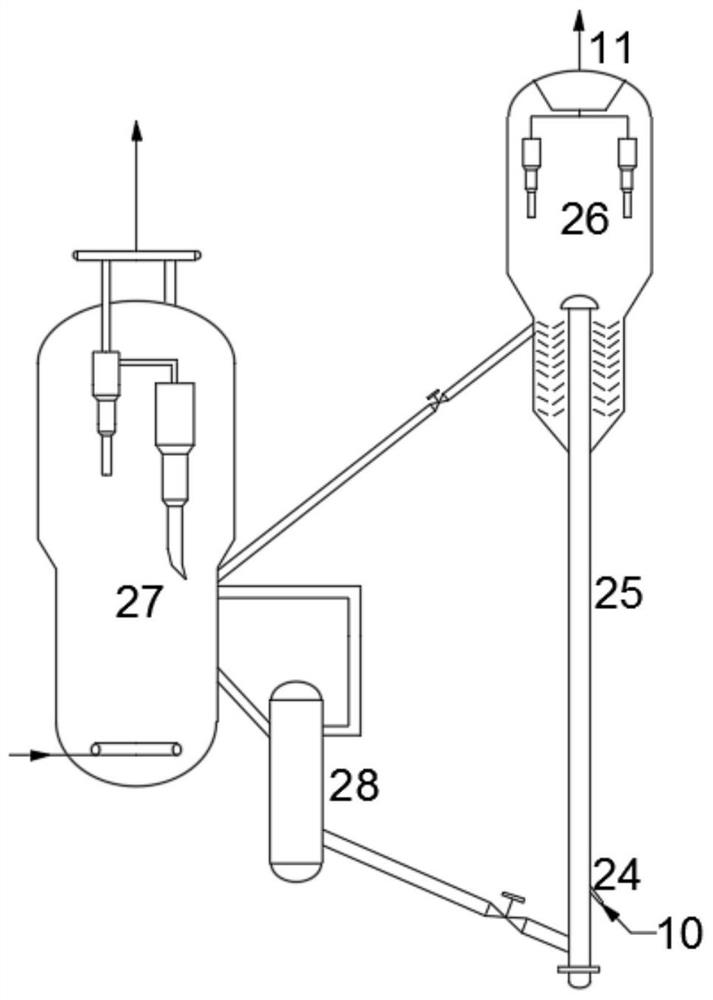

Method used

Image

Examples

preparation Embodiment 1

[0088] The preparation method of C4: mix aluminum sol with kaolin, and use decationized water to prepare it into a slurry with a solid content of 10-50% by weight, stir evenly, and use inorganic salts such as hydrochloric acid, nitric acid, phosphoric acid or sulfuric acid. 1 to 4, keep the pH value, stand and age at 20 to 80°C for 0 to 2 hours, then add aluminum sol, stir for 0.5 to 1.5 hours to form a colloid, add Y-type molecular sieve (produced by Changling Catalyst Factory) to form a catalyst slurry (solid content is 35% by weight), continue to stir and then spray dry to make a microsphere catalyst, wherein Y: kaolin: aluminum sol = 40:39:21. Then the microsphere catalyst was calcined at 500° C. for 1 hour, and washed with ammonium sulfate at 60° C. (wherein, ammonium sulfate: microsphere catalyst: water=0.5:1:10) to a sodium oxide content of less than 0.25% by weight, followed by Rinse with deionized water and filter, and then dry at 110° C., which is the carrier C4 of t...

preparation Embodiment 2

[0091] Using C4 as a carrier, a presulfided catalyst H2 was prepared by a pore saturation impregnation method, wherein the weight ratio of NiS was 10% (based on the total weight of the catalyst).

preparation Embodiment 3

[0093] The preparation method of C3: mix aluminum sol with kaolin, and prepare it into a slurry with a solid content of 10-50% by weight with decationized water, stir evenly, and adjust the pH of the slurry to 1 to 4, keep the pH value, put aluminum sol at 20-80°C for 0-2 hours, then add aluminum sol, stir for 0.5-1.5 hours to form a colloid, add ZSM-5 molecular sieve and Y-type molecular sieve (produced by Changling Catalyst Factory ) to form a catalyst slurry (solid content is 35% by weight), continue to stir and spray dry to make a microsphere catalyst, wherein ZSM-5: Y: kaolin: aluminum sol=20:20:39:21. Then the microsphere catalyst was calcined at 500° C. for 1 hour, and washed with ammonium sulfate at 60° C. (wherein, ammonium sulfate: microsphere catalyst: water=0.5:1:10) to a sodium oxide content of less than 0.25% by weight, followed by Rinse with deionized water and filter, and then dry at 110° C., which is the carrier C3 of this embodiment.

[0094] Catalyst H3 was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com