Method for slagging steelmaking by side blowing of powder particle limestone in top-bottom combined blown converter

A top-bottom combined blowing and limestone technology, applied in the field of metallurgy, can solve the problems of slow decomposition of limestone blocks, limestone is easily taken away by airflow, and low utilization rate of limestone, so as to reduce lime production scale, shorten homogenization time, and The effect of increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

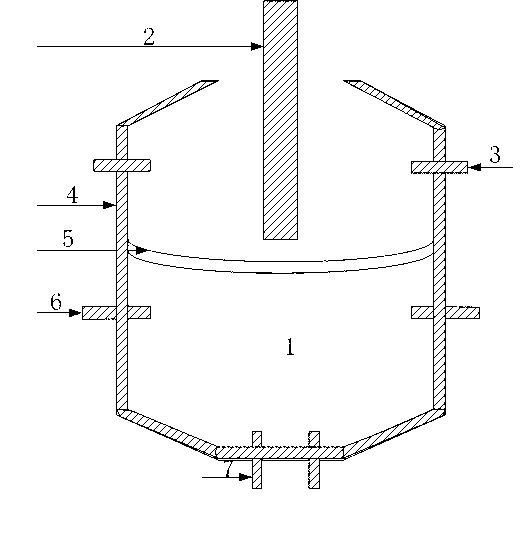

[0024] Four side blowing lances are installed on one side of the trunnion center line of the 100t top-blown converter. The installation point of the side blowing lances is located below the liquid level of the molten pool. The side blowing direction is the angle between the center line of the side blowing lance and the horizontal line of 10°, pointing to the bottom of the molten pool, and the insertion depth of the side blowing lance is 0.1 times the radius of the molten pool.

[0025] Add 100t of molten iron into the converter, shake the furnace body, and lower the top blowing oxygen lance while adding the first batch of slagging agent from the chute above the furnace mouth. The lime content in the slag forming agent is 3000kg. Start the blowing with oxygen supply, after 0.5min of top-blown oxygen lance injection, use side-blown lance with N 2 As the carrier gas, powder limestone is injected, calculated based on the CaO content in the limestone, the injection volume is 10% of...

Embodiment 2

[0027] Two side-blowing spray guns are installed on one side of the trunnion center line of the 100t top-blown converter. The direction of the side blowing is the angle between the center line of the side blowing lance and the horizontal line of 30°, pointing to the bottom of the molten pool, and the insertion depth of the side blowing lance is 0.1 times the radius of the molten pool.

[0028] Add 100t of molten iron into the converter, shake the furnace body, lower the top blowing oxygen lance, and add the first batch of slagging agent from the chute above the furnace mouth. The lime content in the slagging agent is 1300kg. When the oxygen lance is lowered to the specified lance position, oxygen blowing is started. After 0.5 min of blowing with the top-blown oxygen lance, the side-blown lance is used as the carrier gas to inject powdery limestone, calculated based on the CaO content in the limestone. The blowing volume is 60% of the total weight of lime required for converter...

Embodiment 3

[0030] Two side-blowing spray guns are installed on one side of the centerline of the trunnion of the 100t top-blown converter. The direction of the side blowing is 60° between the center line of the side blowing lance and the horizontal line, pointing to the bottom of the molten pool, and the insertion depth of the side blowing lance is 0.3 times the radius of the molten pool.

[0031] Add 100t of molten iron into the converter, shake the furnace body, and lower the top blowing oxygen lance while adding the first batch of slagging agent from the chute above the furnace mouth. The lime content in the slag forming agent is 2400kg. Start the blowing with oxygen supply, after 0.5min of top-blown oxygen lance injection, use side-blown lance with O 2 As the carrier gas, powdery limestone is injected, calculated based on the CaO content in the limestone, the injection volume is 30% of the total weight of lime required for converter steelmaking, the carrier gas pressure of each side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com