Black talcum powder-shaped suspension calcining and whitening device and process

A technology for suspension calcination and black talc, applied in the field of black talc whitening, can solve the problems of difficult to guarantee product quality uniformity, low thermal efficiency of process equipment, high calcination heat consumption, and achieve uniform and controllable temperature distribution and high heat exchange efficiency. , The effect of low system heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

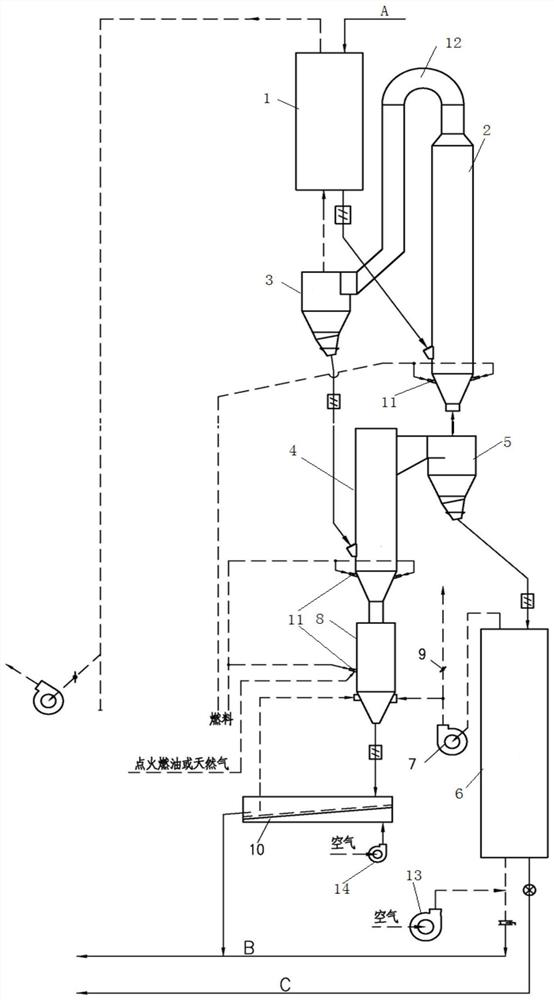

[0032] Such as figure 1 As shown, the invention discloses a black talc powder suspension calcined whitening process, comprising the following steps:

[0033] First, black talc is used as raw material, and black talc powder A is obtained by grinding after ore dressing and crushing;

[0034] Then the black talc powder is preheated by multi-stage series suspension preheater 1, and the preheated black talc powder enters the two-stage series suspension calciner system for calcining and releases the organic matter therein;

[0035] Finally, the calcined talc powder exiting the suspension calciner system enters the multi-stage series suspension cooler 6 for cooling.

[0036]The invention also discloses a device for realizing the above-mentioned process, including a multi-stage series suspension preheater 1, a primary cyclone separator 3, a primary suspension calciner 2, a secondary cyclone separator 5, and a secondary suspension calciner 4 , Multi-stage series suspension cooler 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com