Energy saving and environmental protection active lime roasting shaft kiln

An active lime, energy-saving and environment-friendly technology, which is applied in the field of energy-saving and environment-friendly active lime kiln to produce building materials active magnesite or refractory materials. Combustion air temperature is low and other problems, to achieve the effect of uniform and controllable temperature distribution, simple and reliable equipment, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

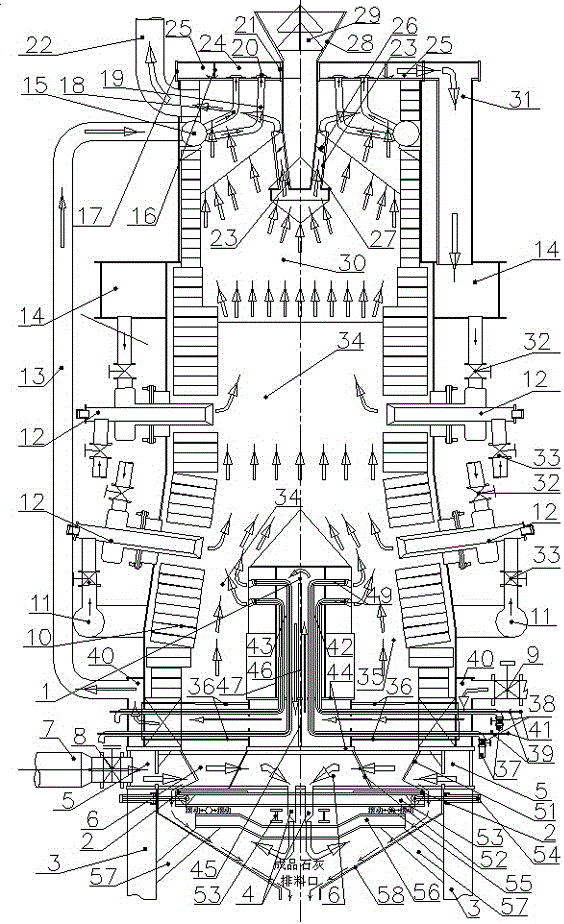

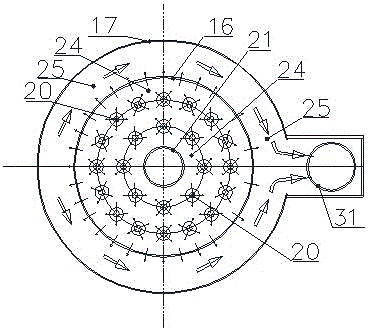

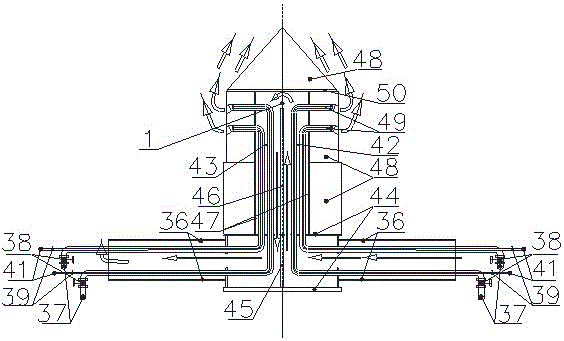

[0029] Combine below Figure 1 to Figure 3 The given examples further illustrate the present invention, but the examples do not constitute any limitation to the present invention.

[0030] An energy-saving and environment-friendly active lime roasting shaft kiln, which consists of a circular furnace body 10, a waste heat recovery device located on the furnace body 10, a kiln roof sealing and material distribution device, a preheating belt 30, a roasting belt 34, and multiple rows of side burners on the furnace wall 12. Large air-cooled central composite burner 1, cooling belt 35, push plate discharge device 2 and load-bearing device.

[0031] The waste heat recovery device is located above the material surface of the furnace body, the kiln roof sealing and material distribution device is located in the middle of the furnace roof, and at least two rows of furnace wall side burners 12 are located near the inflection point of the conical surface of the roasting zone 34 furnace wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com