Spodumene powdery suspension preheating calcination crystal form transformation process

A technology for spodumene powder and crystal transformation, which is applied in the field of lithium extraction from spodumene, can solve the problems of increased power consumption of the grinding section system, long calcination time, difficult temperature control, etc., and achieves uniform and controllable temperature distribution. The effect of comprehensive energy consumption and low cost, and fast heat exchange speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

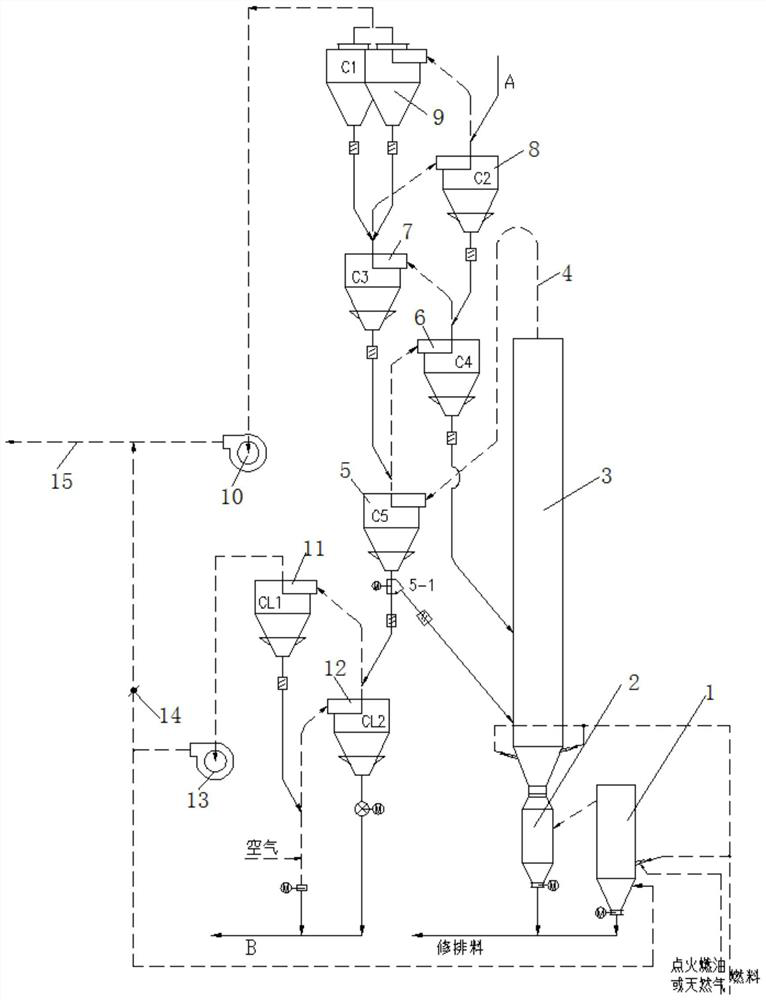

[0034] Such as figure 1 As shown, the present invention discloses a spodumene powder suspension preheating calcining crystal transformation process, comprising the following steps:

[0035] Crush the massive α-spodumene with a water content of less than 8% (the particle size is generally less than 40mm), and grind it to obtain a fine powder of α-spodumene with a water content of less than 1% (fineness R0.08 sieve 5~ 25%), the α-type spodumene fine powder is collected by the cyclone dust collector, and sent to the powder homogenization warehouse by bucket elevator and other conveying equipment, and the homogenized α-type spodumene powder is measured by the steady flow The bucket elevator feeds into the suspension preheater.

[0036] The raw material α-type spodumene powder A is fed into the inlet pipe of preheater C1 cyclone 9, preheated step by step by preheater C2~C4 cyclone 8, 7, 6, collected by preheater C4 cyclone 6, and then enters the suspension Calciner 3.

[0037] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com