Process for producing calcined gypsum and gypsum board

一种制造方法、熟石膏的技术,应用在钙/锶/钡硫酸盐等方向,能够解决凝固时间延长、石膏板物理性质下降、制造熟石膏成本增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

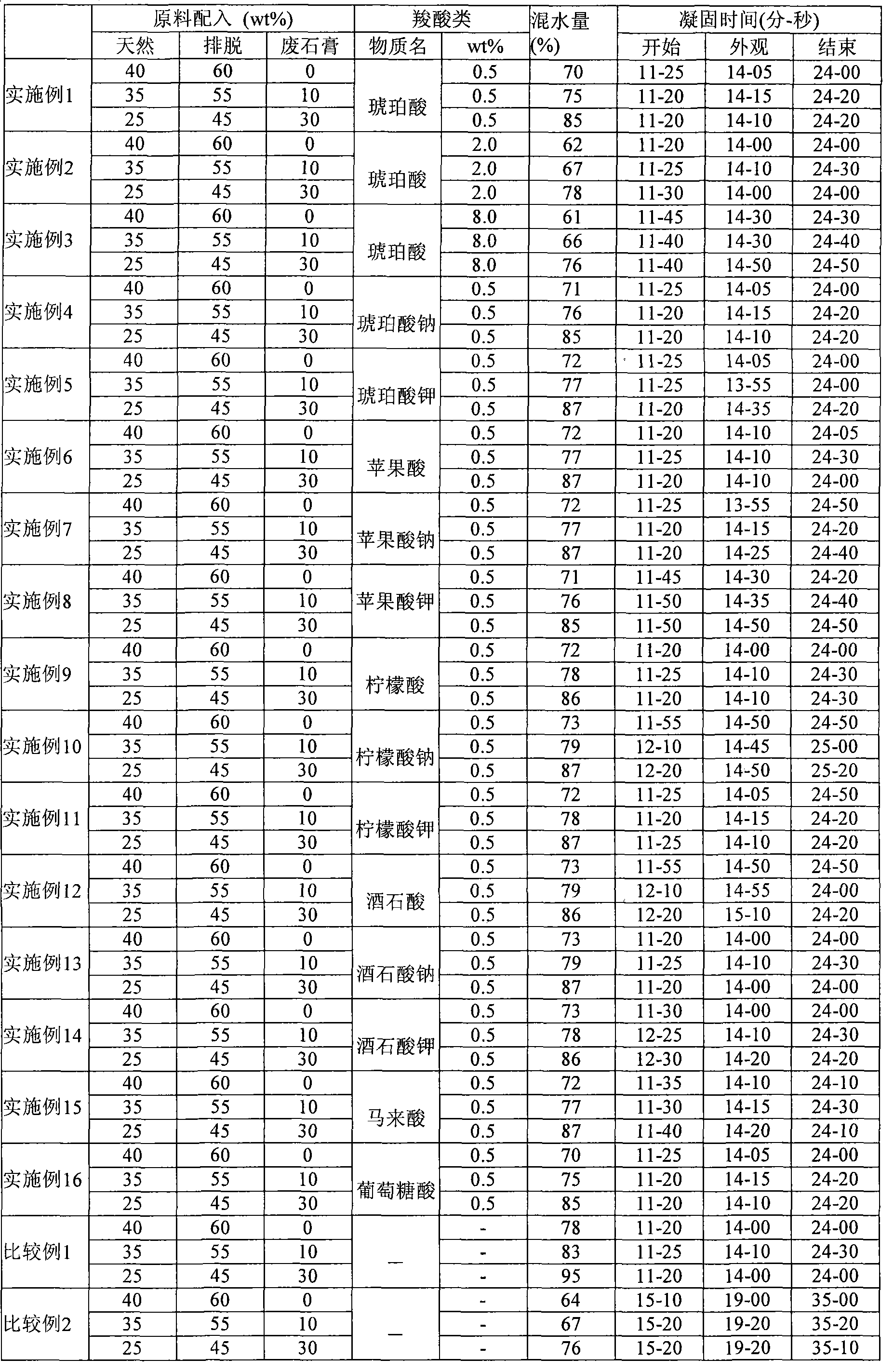

Embodiment 1

[0032] A mixture in which 0.50 wt% of succinic acid was blended with respect to the raw gypsum to 3 kg of the raw gypsum was obtained. The mixture was charged into a small pot, and the firing temperature was set at 165° C. to obtain plaster of paris. Let the plaster of paris cool down to room temperature, then use a small ball mill to pulverize it, and adjust the specific surface area of the plaster of paris to about 8000cm 2 / g.

Embodiment 2

[0034] A mixture in which 2.0 wt% of succinic acid was blended with respect to the raw gypsum was obtained in 3 kg of raw gypsum. The mixture was charged into a small pot, and the firing temperature was set at 165° C. to obtain plaster of paris. Let the plaster of paris cool down to room temperature, then use a small ball mill to pulverize it, and adjust the specific surface area of the plaster of paris to about 8000cm 2 / g.

Embodiment 3

[0036] A mixture in which 8.0 wt % of succinic acid was blended with 3 kg of raw gypsum was obtained. The mixture was charged into a small pot, and the firing temperature was set at 165° C. to obtain plaster of paris. Let the plaster of paris cool down to room temperature, then use a small ball mill to pulverize it, and adjust the specific surface area of the plaster of paris to about 8000cm 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com