Plug assembly for beverage container

A beverage and container technology, applied in the field of plugs, can solve problems such as loud clicks of plugs, hinder miniaturization, and unsanitary, and achieve the effects of easy operation, suppressing clicks, and stable injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

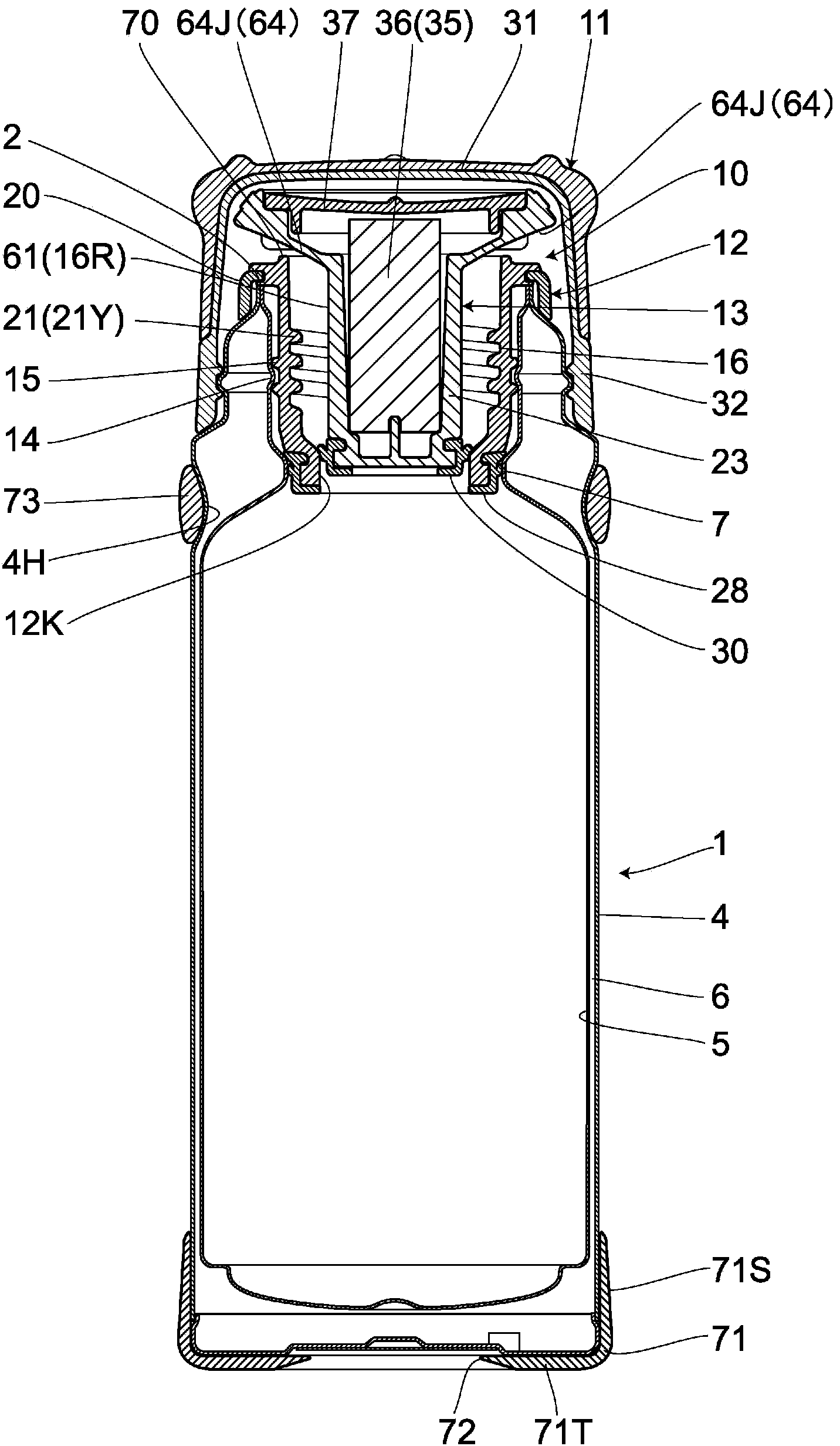

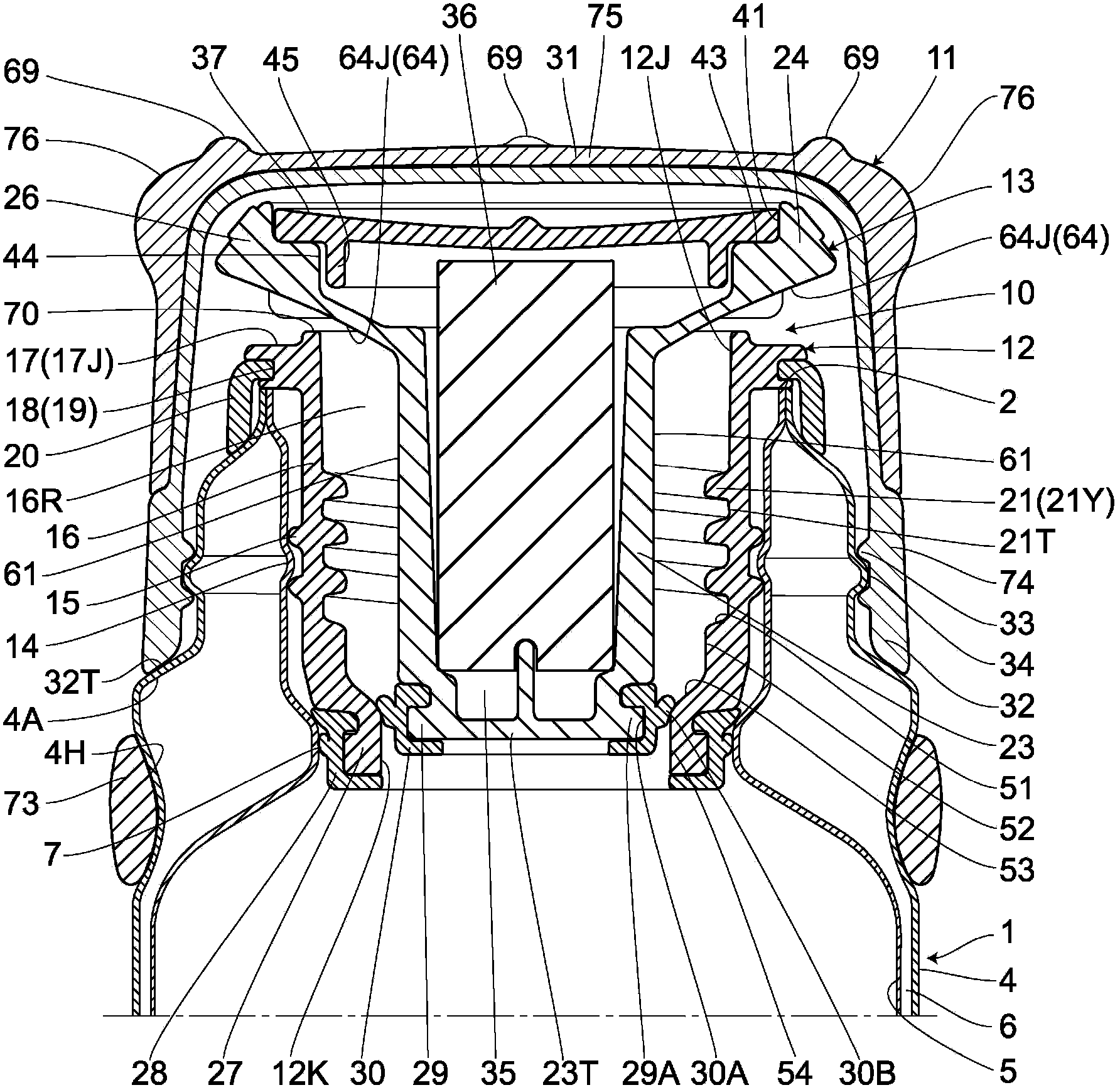

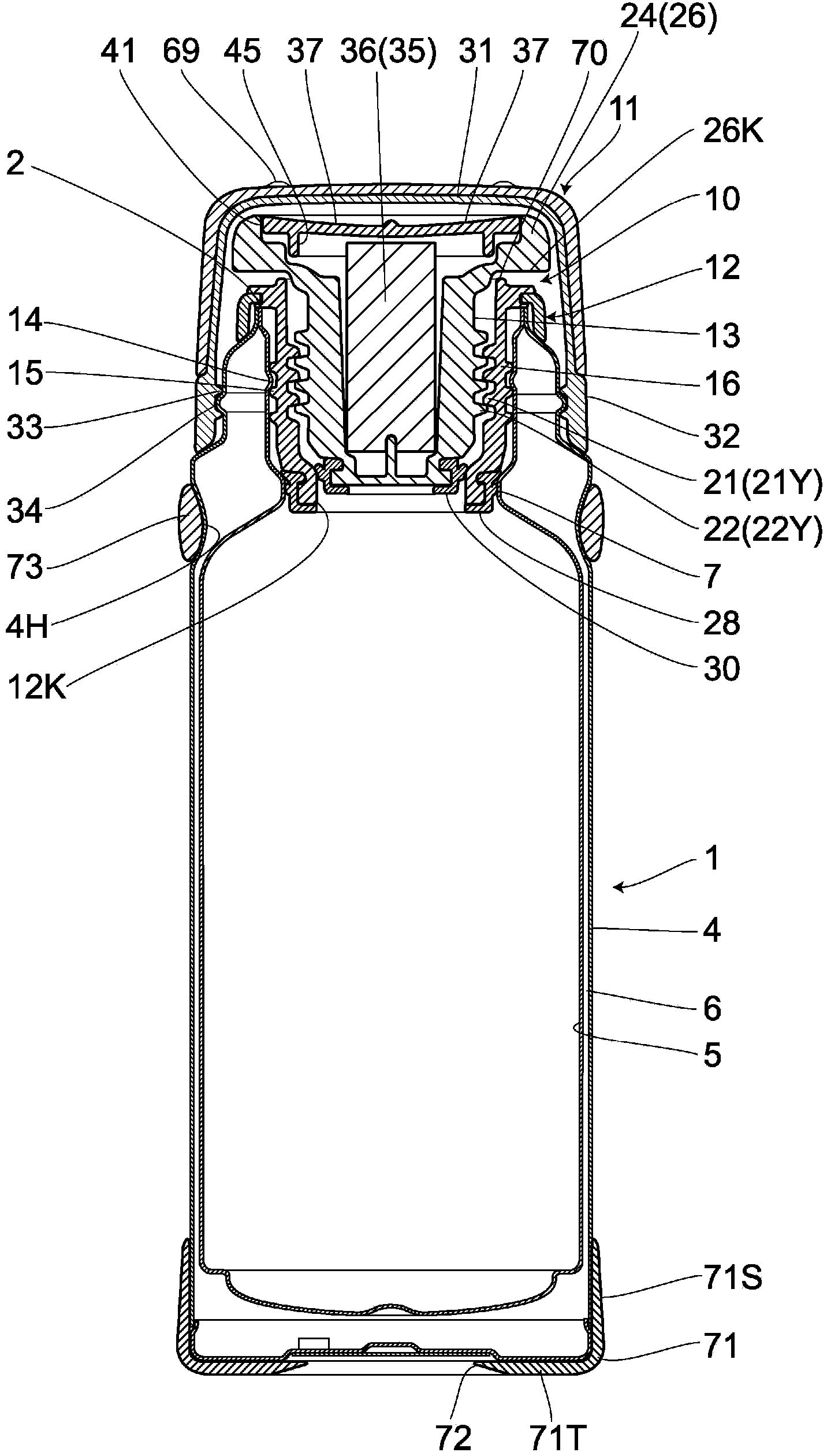

[0034] Figure 1 to Figure 9 Example 1 is shown, in which a plug body 10 is detachably provided in the upper opening portion 2 of a beverage container body 1 made of metal or resin, which is a container. The beverage container body 1 has a bottomed inner cylinder 5 of stainless steel inside a bottomed outer cylinder 4 of stainless steel, and the outer cylinder 4 and inner cylinder 5 are joined together to form a wide-mouthed upper opening 2 . Furthermore, a heat-insulating double container is formed by using the vacuum layer 6 as a heat-insulating layer between the outer cylinder 4 and the inner cylinder 5 . In addition, the protrusion 7 is provided inwardly in a stepwise manner substantially below the upper opening 2 in the inner cylinder 5 .

[0035] A plug 10 made of synthetic resin is detachably covered on the upper opening 2 of the metal beverage container body 1, and a lid 11 is detachably provided to cover the upper opening 2. Body 11 becomes a water cup.

[0036] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com