Growth equipment for preparation of magnesium fluoride crystals with multi-crucible descending method and growth method of magnesium fluoride crystals

A technology for preparing magnesium fluoride and a growth method, which is applied in crystal growth, polycrystalline material growth, single crystal growth, etc., can solve the problems of low growth efficiency, achieve high production efficiency, easy control of shape and size, and excellent optical quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

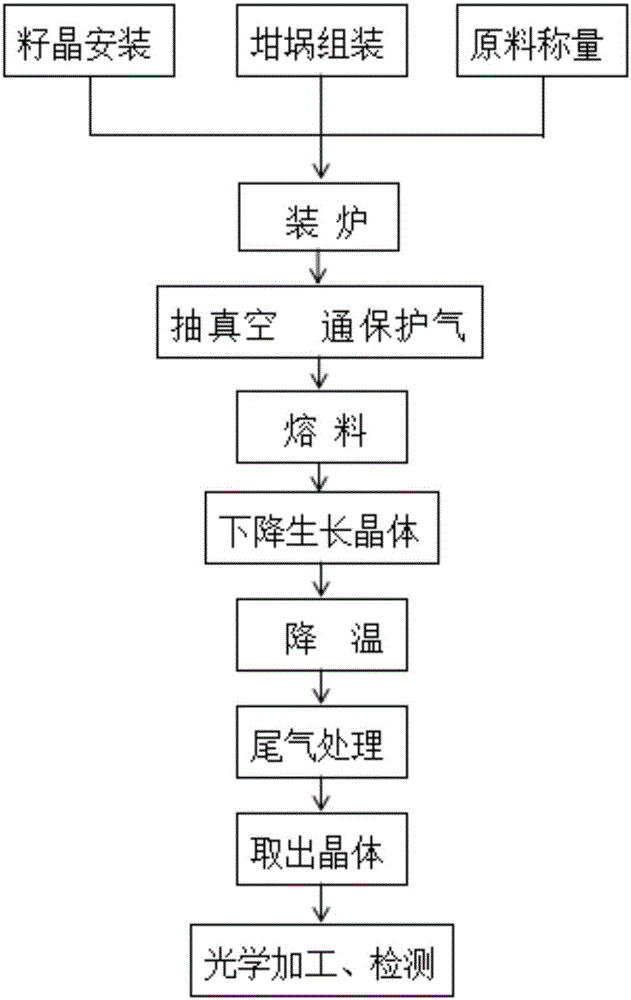

Method used

Image

Examples

Embodiment 1

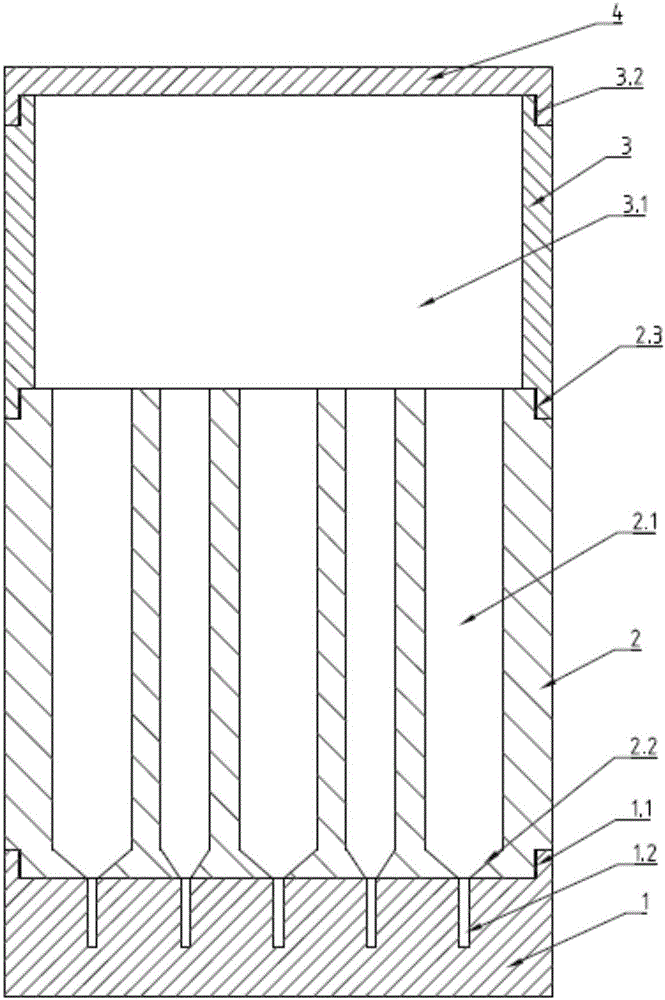

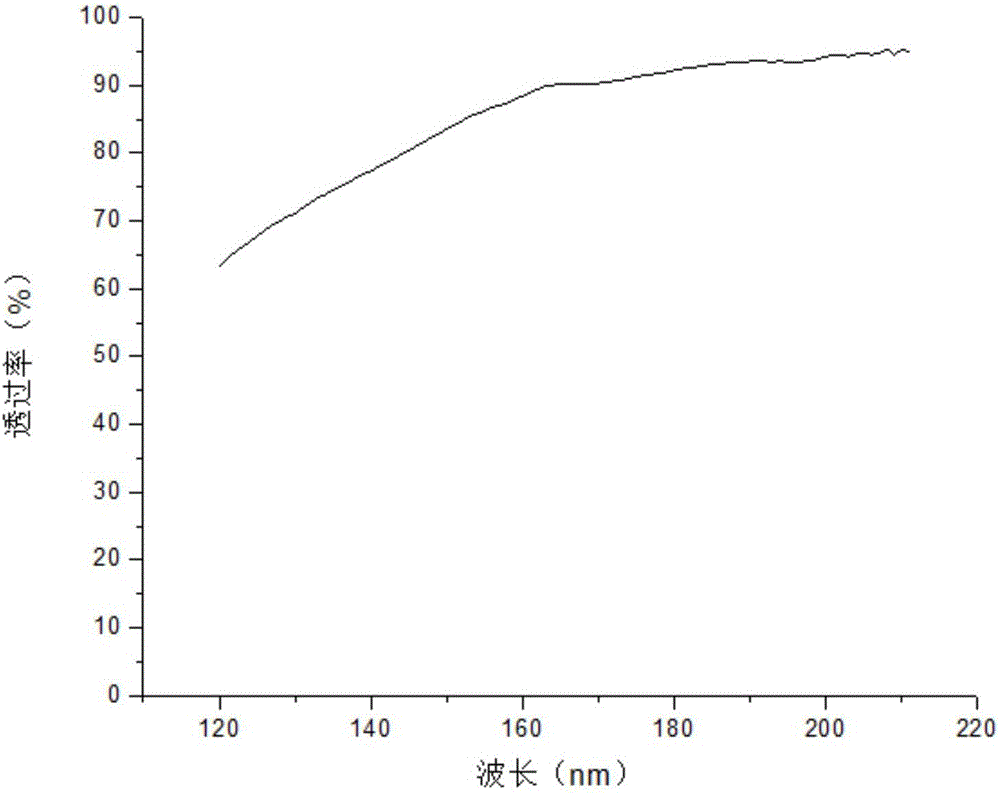

[0027] Embodiment 1: The selected crucible is a 15-hole graphite crucible, and the crystal growth area is all cylindrical, with a diameter of 33 mm and a length of 200 mm. Load the preferred magnesium fluoride crystal seed crystal into the seed crystal area, assemble the graphite crucible, load 8.2 kg of crystal raw material magnesium fluoride powder into the crystal growth area and the feed bin, and cover the crucible lid. Put the crucible into the crystal growth furnace, and evacuate until the vacuum degree reaches 1.0×10 -3 After Pa, filled with 60%:40% Ar and CF 4The mixed gas makes the pressure in the furnace reach 0.11MPa. Turn on the medium-frequency induction heating power supply, start to heat up the molten material at a heating rate of 10-100°C / h, and after the magnesium fluoride raw material is completely melted, perform a constant temperature overheating treatment for 10 hours, and then prepare magnesium fluoride crystals at a falling rate of 2.0mm / h. After falli...

Embodiment 2

[0029] Embodiment 2: The selected crucible is a 3-hole graphite crucible, and the crystal growth area is all cylindrical, with a diameter of 76 mm and a length of 200 mm. Load the preferred magnesium fluoride crystal seed crystal into the seed crystal area, assemble the graphite crucible, load 8.3 kg of crystal raw material magnesium fluoride powder into the crystal growth area and the feed bin, and cover the crucible lid. Put the crucible into the crystal growth furnace, and evacuate until the vacuum degree reaches 1.0×10 -3 After Pa, fill with 60%:40% Ar and CF 4 The mixed gas makes the pressure in the furnace reach 0.11MPa. Turn on the medium-frequency induction heating power supply, start to heat up the molten material at a heating rate of 10-100°C / h, and after the magnesium fluoride raw material is completely melted, perform a constant temperature overheating treatment for 10 hours, and then prepare magnesium fluoride crystals at a falling rate of 1.5mm / h. After falling...

Embodiment 3

[0031] Embodiment 3: The selected crucible is an 8-hole graphite crucible, and the crystal growth area is all cylindrical, with a diameter of 40 mm and a length of 200 mm. Load the preferred magnesium fluoride crystal seed crystal into the seed crystal area, assemble the graphite crucible, load the crystal raw material magnesium fluoride powder 6.4kg into the crystal growth area and the feed bin, and cover the crucible lid. Put the crucible into the crystal growth furnace, and evacuate until the vacuum degree reaches 1.0×10 -3 After Pa, fill with 70%:30% Ar and CF 4 The mixed gas makes the pressure in the furnace reach 0.11MPa. Turn on the medium-frequency induction heating power supply, start to heat up the molten material at a heating rate of 10-100°C / h, and after the magnesium fluoride raw material is completely melted, perform a constant temperature overheating treatment for 10 hours, and then prepare magnesium fluoride crystals at a falling rate of 2.0mm / h. After fallin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com