Medical porous polyether-ether-ketone with drug loading function and preparing method and application thereof

A polyether ether ketone, a technology for a manufacturing method, applied in the field of medical drug-carrying porous polyether ether ketone and the preparation thereof, can solve the problems of insufficient bonding, ineffective implants, easy detachment of coatings, etc. The effect of low manufacturing cost, excellent mechanical properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A titanium wire with a diameter of 0.05mm is used to wind and weave it into a set shape with a porosity of 10%. The molten polyether ether ketone is injected into the pores of porous titanium through die casting, and then hydrofluoric acid with a concentration of 10% is passed. Corroded for 12 hours, a porous polyether ether ketone with a pore size of 0.05mm and a porosity of 90% was formed. The laser cladding method was used to load tantalum powder in the pores. Tantalum has excellent biocompatibility and can effectively improve the osseointegration ability of the material . The compressive yield strength of the material is 1MPa, and the elastic modulus is 0.1GPa, which is suitable for bone repair and bone implantation under non-stressed conditions.

Embodiment 2

[0034] A titanium wire with a diameter of 0.2mm is used to wind and weave it into a set shape with a porosity of 30%. The molten polyether ether ketone is injected into the pores of porous titanium through die casting, and then hydrofluoric acid with a concentration of 10% is passed. Corrosion for 8 hours to form a porous polyetheretherketone with a pore size of 0.2 mm and a porosity of 70%. The hydroxyapatite slurry is loaded in the pores and then solidified. The hydroxyapatite has excellent biocompatibility and can promote implantation The body forms a firm bond with the bone. The compressive yield strength of the material is 10MPa, and the elastic modulus is 2GPa, which is suitable for bone repair and bone implantation under non-stressed conditions.

Embodiment 3

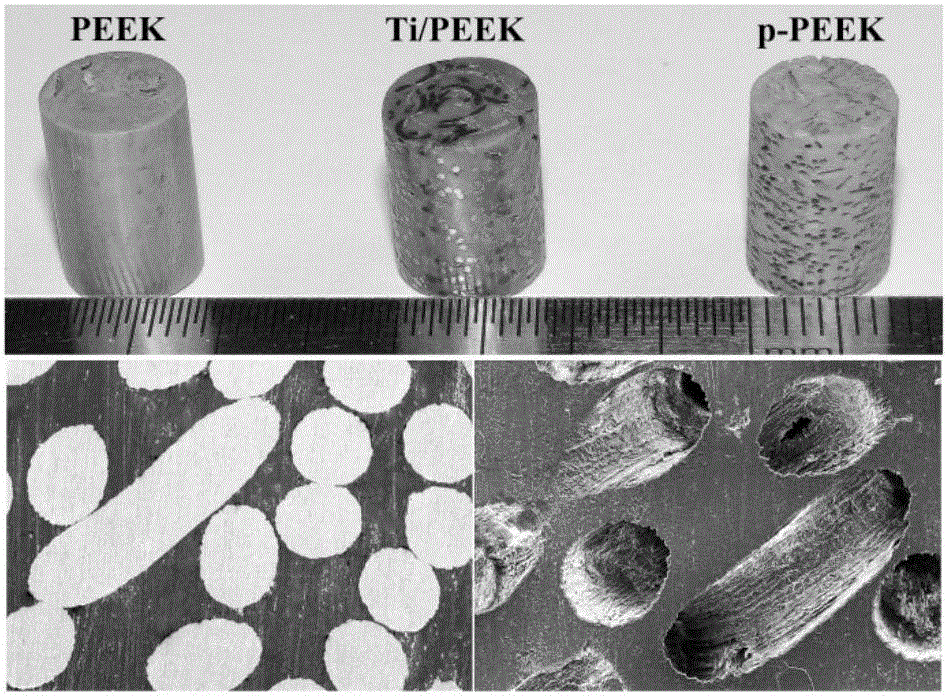

[0036] A titanium wire with a diameter of 0.4mm is used to wind and weave it into a set shape with a porosity of 50%. The molten polyether ether ketone is injected into the pores of porous titanium through die casting, and then hydrofluoric acid with a concentration of 10% is passed After being corroded for 8 hours, a porous polyetheretherketone with a pore size of 0.4mm and a porosity of 50% is formed, and its appearance is as follows: figure 1 As shown, the embedding method was used to load vancomycin in the wells. Vancomycin is a commonly used clinical antibiotic at present. The chance of implant surgery failing. The material has a compressive yield strength of 30MPa and an elastic modulus of 5GPa, making it suitable for bone repair and bone implantation under stress loading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com