Induction heating upsetting device for aluminum alloy cylinder

An induction heating and aluminum alloy technology, applied in metal processing equipment, forging/pressing/hammer devices, heating/cooling equipment, etc., can solve problems such as difficult operation, welding deformation, large heat input, etc., to achieve simple operation and convenience Automated, easy-to-control pier size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

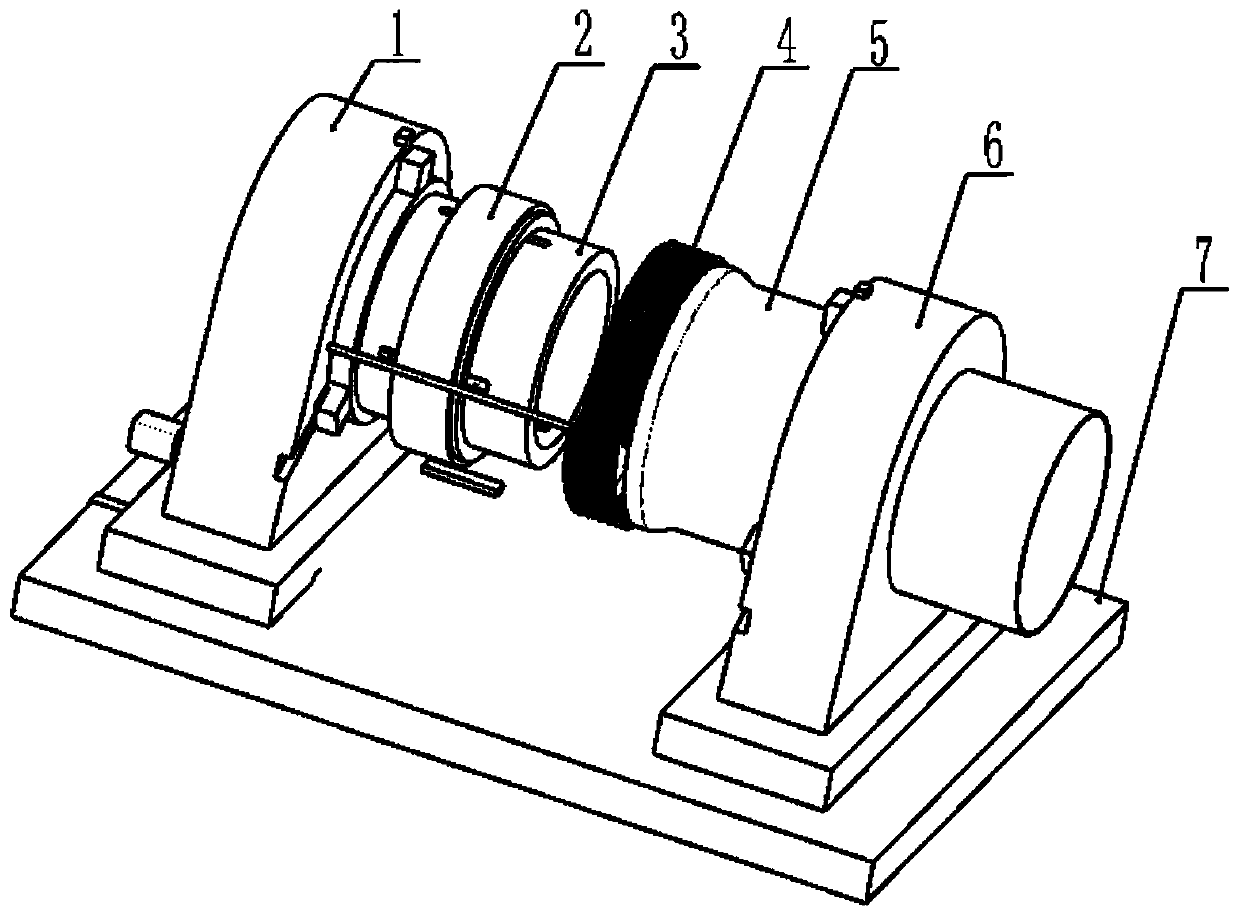

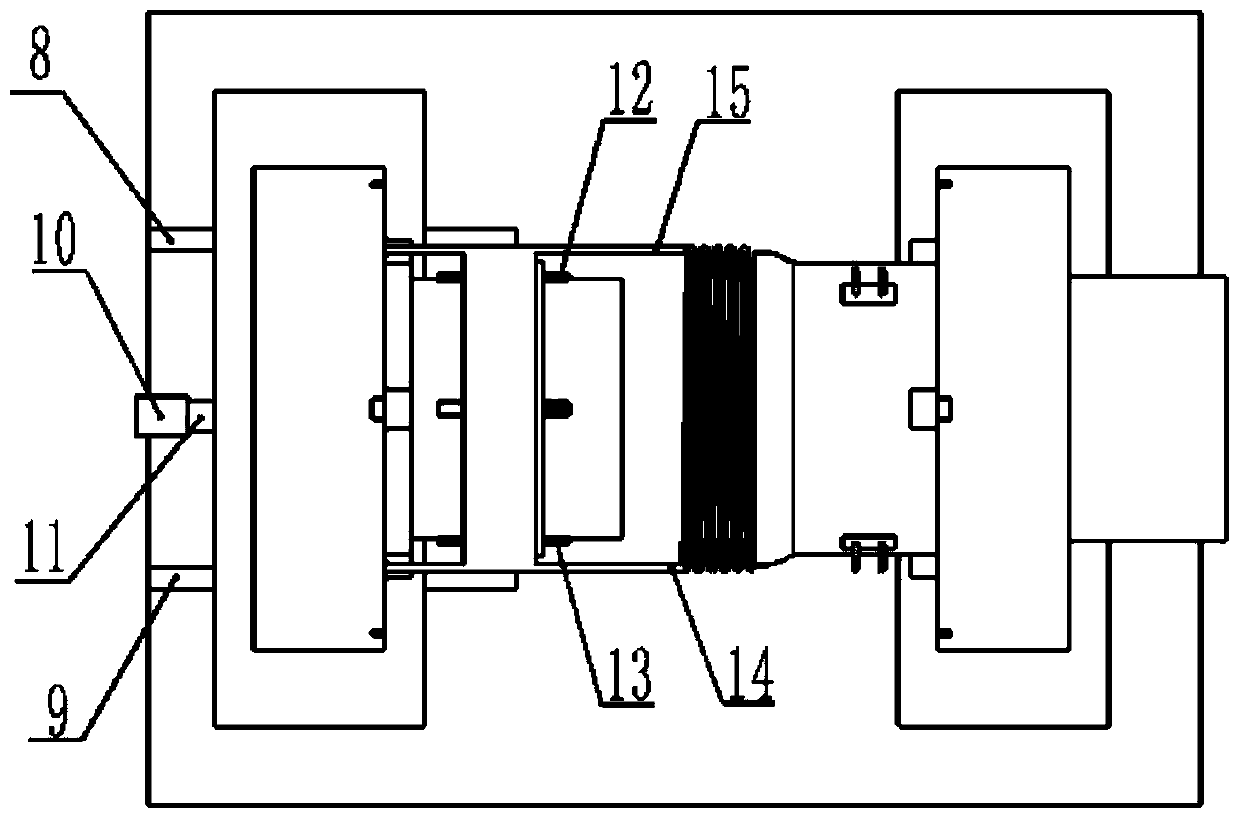

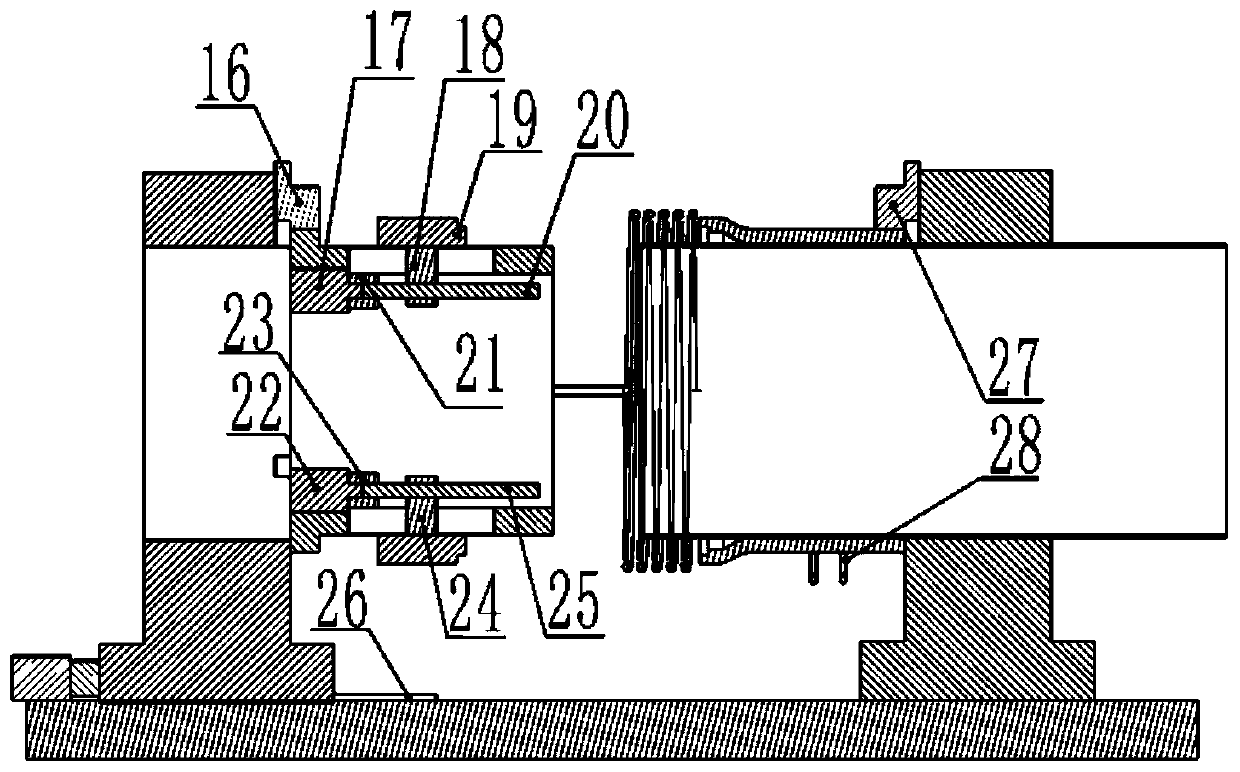

[0020] Such as Figure 1 to Figure 3 An aluminum alloy cylinder induction heating pier thickening device shown includes a headstock 1, a pier thickening mechanism 2, a pier thickening support ring 3, an induction coil 4, a forming die 5, and a tailstock 6; the pier thick support ring 3 The front end of the pier is installed on the head seat 1, the pier thick support ring 3 is set with the pier thick mechanism 2, the rear end of the pier thick support ring 3 has an induction coil 4 fixed on the front end of the forming mold 5, and the rear end of the forming mold 5 is fixed on the On the tailstock 6; the central axis of the pier thick support ring 3, the induction coil 4, and the forming die 5 are on the same straight line; the pier thick support ring 3 can move axially relative to the induction coil 4; the pier thick support ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com