A kind of sodium vanadium fluorophosphate and its preparation method and application

A technology of vanadium sodium salt of fluorophosphate and organic phosphoric acid, which is applied to structural parts, electrical components, battery electrodes, etc., can solve problems such as difficult operation and high energy consumption, and achieve resource and cost saving, high discharge specific capacity, and electrochemical The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

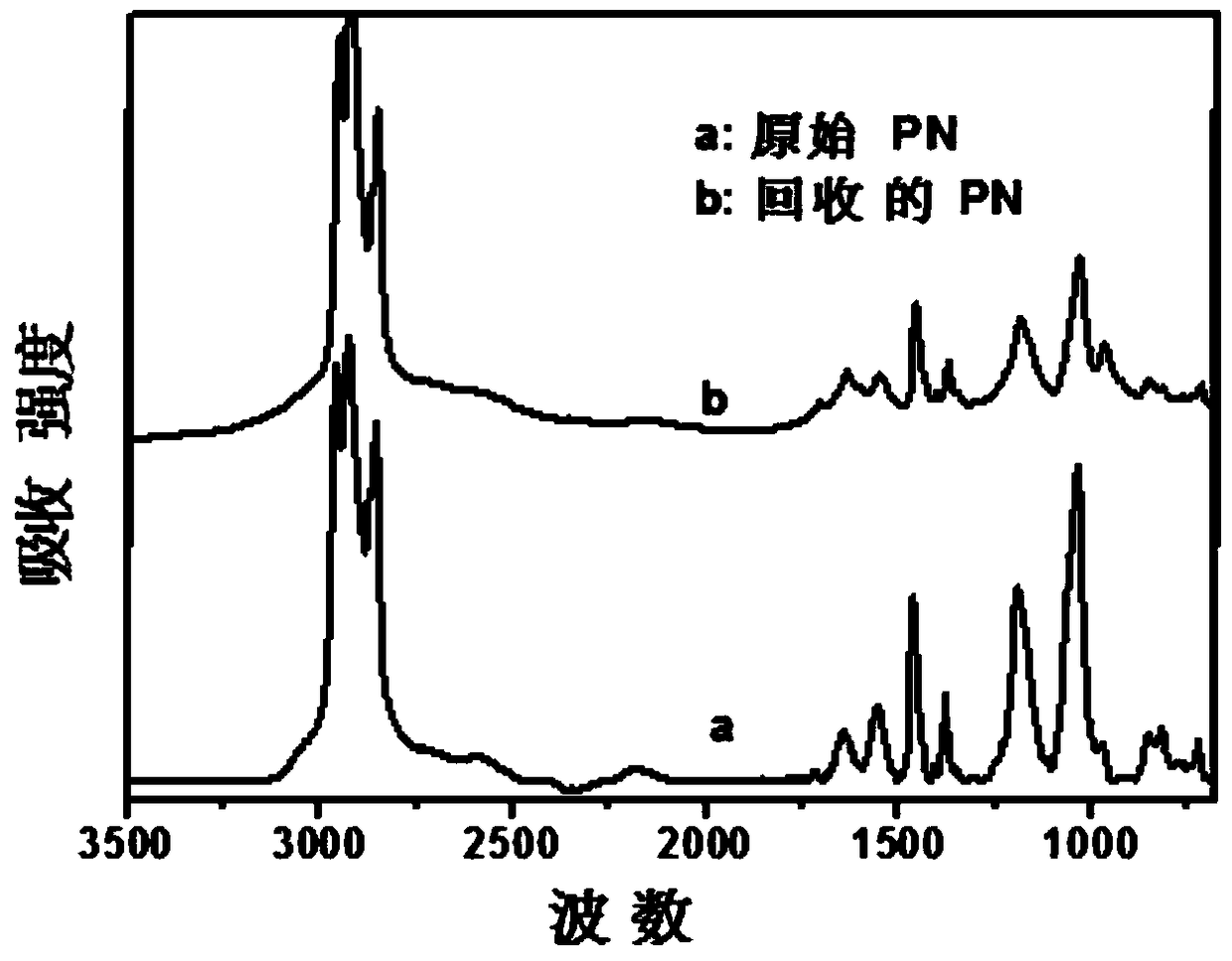

[0055] P507 and N1923 are mixed in molar ratio 1:1 to obtain mixed extractant PN; 10g mixed extractant is dissolved in 50ml n-heptane, and its mass volume percent concentration is 20%; 25ml above-mentioned PN-n-heptane solution is mixed with 2ml Commercial concentrated phosphoric acid is mixed into a homogeneous phase (the volume ratio of PN-n-heptane solution to commercial concentrated phosphoric acid is 12.5:1), and the concentration of phosphoric acid is 2mol / L to obtain 4 3- Microemulsion phase with a concentration of about 1.06mol / L; 0.180g vanadium acetylacetonate, 1.5mL containing PO4 3- The above-mentioned microemulsion phase, 0.035g sodium fluoride (Na:V:P:F is about 1.6:1:3:1.6) are ultrasonically dispersed in 1.5mL ethanol and 0.5mL acetone to obtain a uniformly mixed reaction material; Transfer the uniformly mixed material into a hydrothermal reaction kettle, raise the temperature to 120°C at a rate of 5°C per minute, and keep the temperature at this temperature f...

Embodiment 2

[0057] Mix Cyanex272 and N1923 at a molar ratio of 1:1 to obtain a mixed extractant; dissolve 10 g of the mixed extractant in 100 ml of n-heptane, and its mass volume percentage concentration is 10%; mix 25 ml of the above PN-n-heptane solution with 4 ml of commercial Concentrated phosphoric acid is mixed into a homogeneous phase, (the volume ratio of PN-n-heptane solution to commercial concentrated phosphoric acid is 6.25:1), and the concentration of phosphoric acid is 3mol / L to obtain 4 3- Microemulsion phase with a concentration of about 2.0mol / L; 0.137g vanadyl acetylacetonate, 0.75mL containing PO 4 3-The above-mentioned microemulsion phase, 0.035g sodium fluoride (Na:V:P:F is about 1.6:1:3:1.6) are ultrasonically dispersed in 1.5mL ethanol and 0.5mL acetone to obtain a uniformly mixed reaction material; Transfer the uniformly mixed material into a hydrothermal reaction kettle, raise the temperature to 120°C at a rate of 5°C per minute, and keep the temperature at this ...

Embodiment 3

[0059] Except that 20g mixed extractant is dissolved in 100ml n-hexane, and its mass volume percent concentration is 20%; the volume ratio of PN-n-heptane solution to commercial concentrated phosphoric acid is 3.85:1, and wherein the phosphoric acid concentration is 1mol / L, to obtain PO-containing 4 3- Microemulsion phase; according to Na:V:P:F about 1:1:1:1, vanadium tribromide, containing PO 4 3- The above microemulsion phase, hydrofluoric acid and sodium dihydrogen phosphate were ultrasonically dispersed in 1.5mL ethanol and 0.5mL acetone; the temperature was raised to 140°C at a heating rate of 4°C per minute, and kept at this temperature for 5h; Dry in the air for 2 hours, and the rest of the steps are the same as in Example 1.

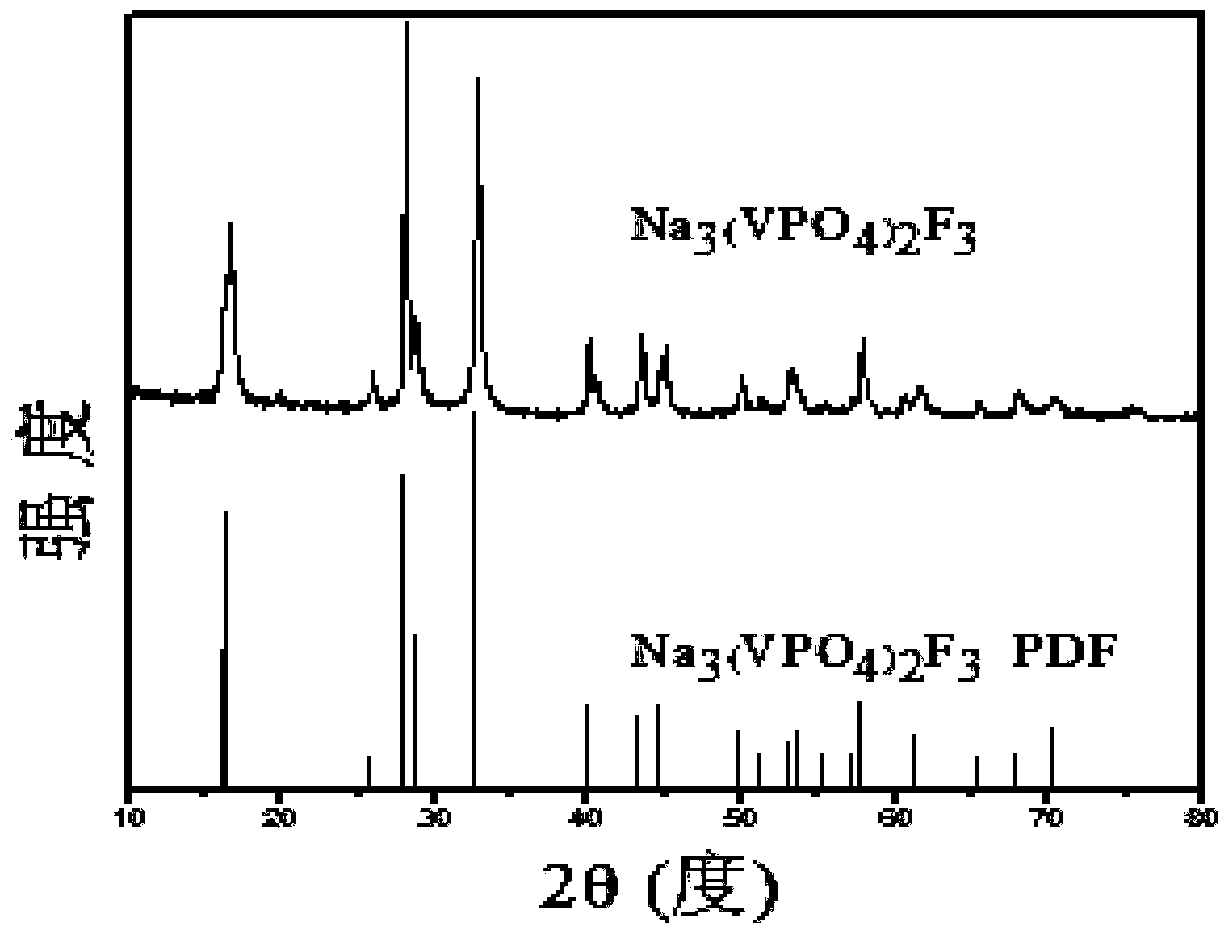

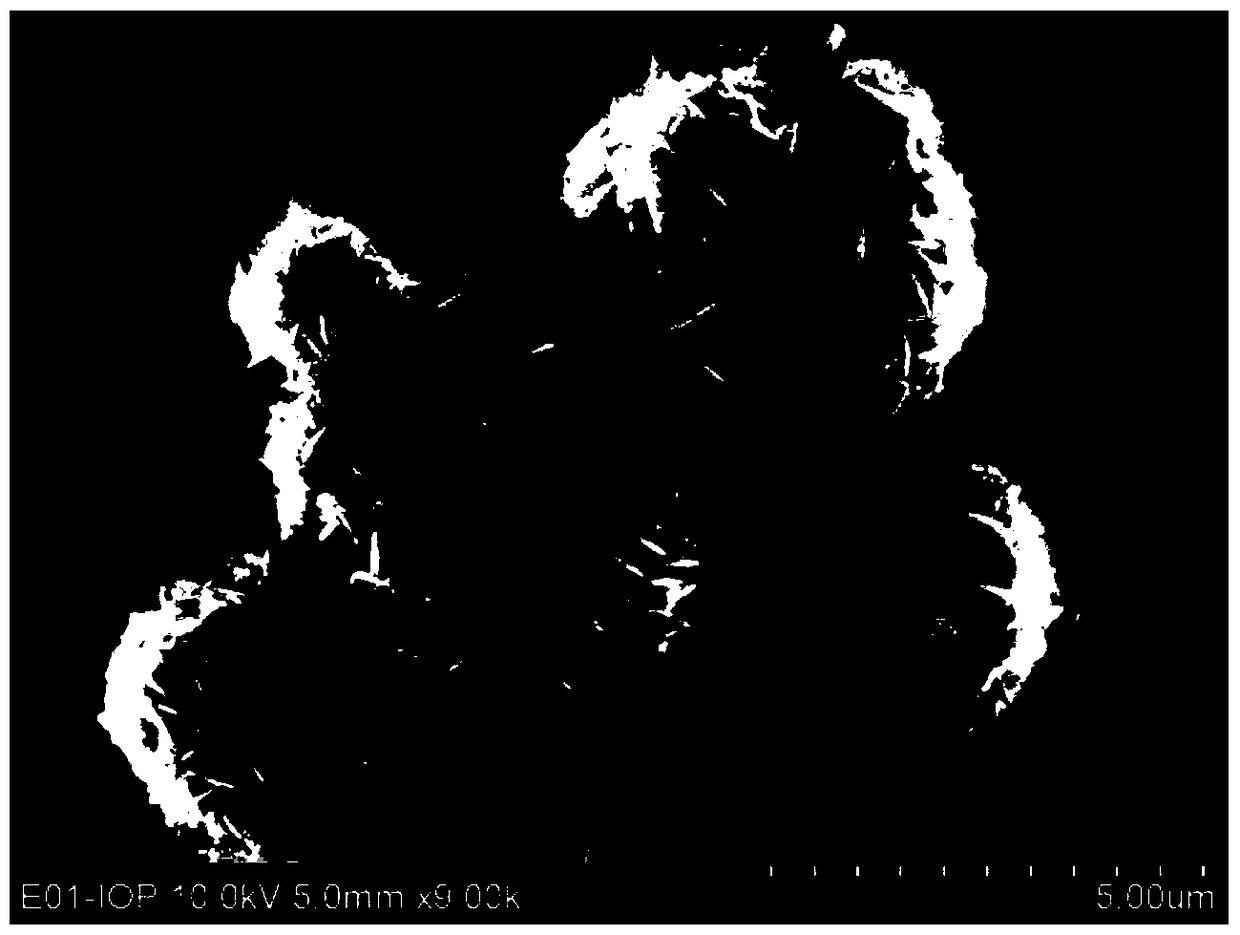

[0060] Product 0.092 is weighed, and productive rate is close to 90%, and XRD shows that product is Na 3 (VPO 4 ) 2 f 3 , has the characteristics of good crystallinity and high purity; the upper organic phase is volatilized to remove the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com