Ultraviolet curing adhesive for insulation protection, preparation method and application thereof

A technology for insulating protection and curing adhesives, applied in the field of curing adhesives, can solve the problems of low viscosity, low surface energy, and easy sagging of curing adhesives, and achieve the effects of simple preparation process, good processing performance, and avoiding the risk of aluminum exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

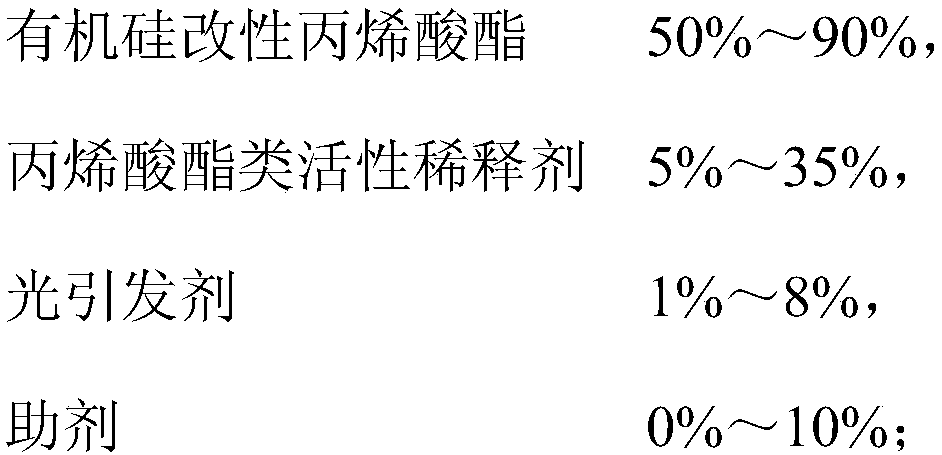

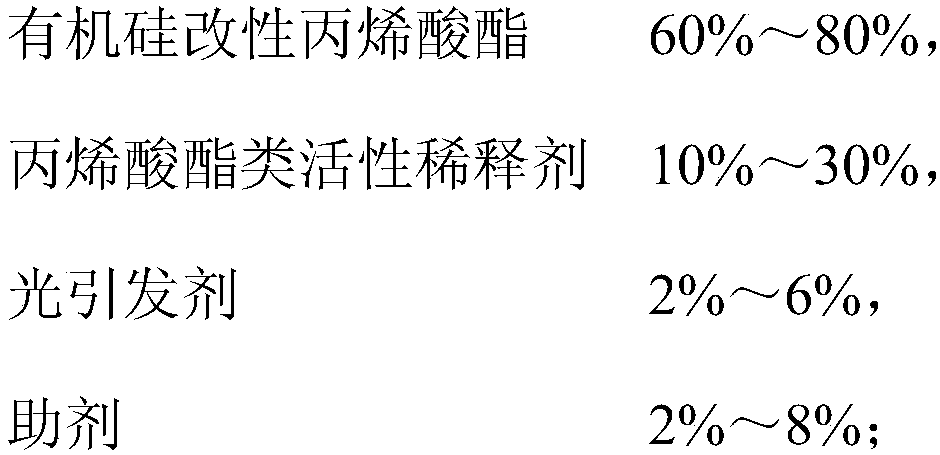

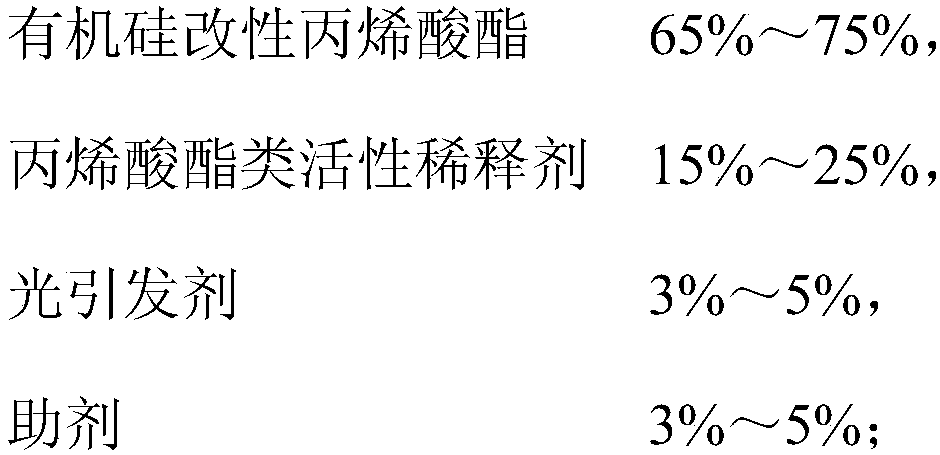

Method used

Image

Examples

Embodiment 1

[0029] In a 500 ml glass four-neck flask equipped with a stirrer and a condenser, first take 140 grams of hydroxyl-terminated polydimethylsiloxane with a molecular weight between 1000 and 1500 and an average functionality of 2, and pump it at 105 ° C. Remove water under vacuum for 3 hours, then cool it down to 45°C, stop vacuuming, add 16.4 grams of methane dicyclohexyl diisocyanate, and stir rapidly. After the temperature is stable, slowly raise the temperature and control the temperature at 80°C for 2.5 hours. After the reaction is complete, cool down to 45°C, add 5.3 grams of hydroxyethyl acrylate, and add 0.05 grams of hydroquinone as a polymerization inhibitor, slowly raise the temperature to 75°C and react for 2.5 hours, and vacuum degas for 0.5 hours after the reaction is complete. The obtained silicone modified acrylate is sealed and protected from light for future use.

[0030] Accurately weigh 78.6 grams of the above-mentioned silicone modified acrylate, 15 grams of ...

Embodiment 2

[0032] In a 500 ml glass four-neck flask equipped with a stirrer and a condenser tube, first take 185 grams of hydroxyl-terminated polydimethylsiloxane with a molecular weight between 1500 and 1800 and an average functionality of 2.5, and pump it at 115 ° C. Remove water in vacuum for 2 hours, then cool it down to 40°C, stop vacuuming, add 21.1 grams of methane dicyclohexyl diisocyanate, stir rapidly, after the temperature is stable, slowly raise the temperature and control the temperature at 75°C for 3 hours, After the reaction is complete, the temperature is lowered to 40°C, 6.4 grams of hydroxyethyl methacrylate and 5.0 grams of hydroxypropyl acrylate are added, and 0.08 grams of polymerization inhibitor p-hydroxyanisole is added, and the temperature is slowly raised to 70°C for 3 hours. After the reaction was complete, vacuum degassed for 0.5 hours, and the material was obtained to obtain a silicone-modified acrylate, which was sealed and protected from light for future use...

Embodiment 3

[0035] In a 500 ml glass four-neck flask equipped with a stirrer and a condenser, first take 215 grams of hydroxyl-terminated polydimethylsiloxane with a molecular weight between 1500 and 1800 and an average functionality of 3, and pump it at 100 ° C. Remove water under vacuum for 4 hours, then cool it down to 50°C, stop vacuuming, add 23.7 grams of methane dicyclohexyl diisocyanate, and stir rapidly. After the temperature is stable, slowly raise the temperature and control the temperature at 85°C for 2 hours. After the reaction is complete, cool down to 50°C, add 4.3 grams of hydroxyethyl acrylate, 2.5 grams of hydroxypropyl methacrylate and 5.7 grams of hydroxypropyl acrylate, and add 0.09 grams of polymerization inhibitor p-hydroxyanisole, slowly Raise the temperature to 80°C and react for 2 hours. After the reaction is complete, vacuum degassing for 0.5 hours. The material is taken out to obtain the silicone-modified acrylate, which is sealed and protected from light for fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com