Patents

Literature

133results about How to "Play the role of insulation protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary battery

ActiveCN111326699AReduced risk of short circuitsImprove safety performanceCell electrodesSmall-sized cells cases/jacketsPhysicsElectrical battery

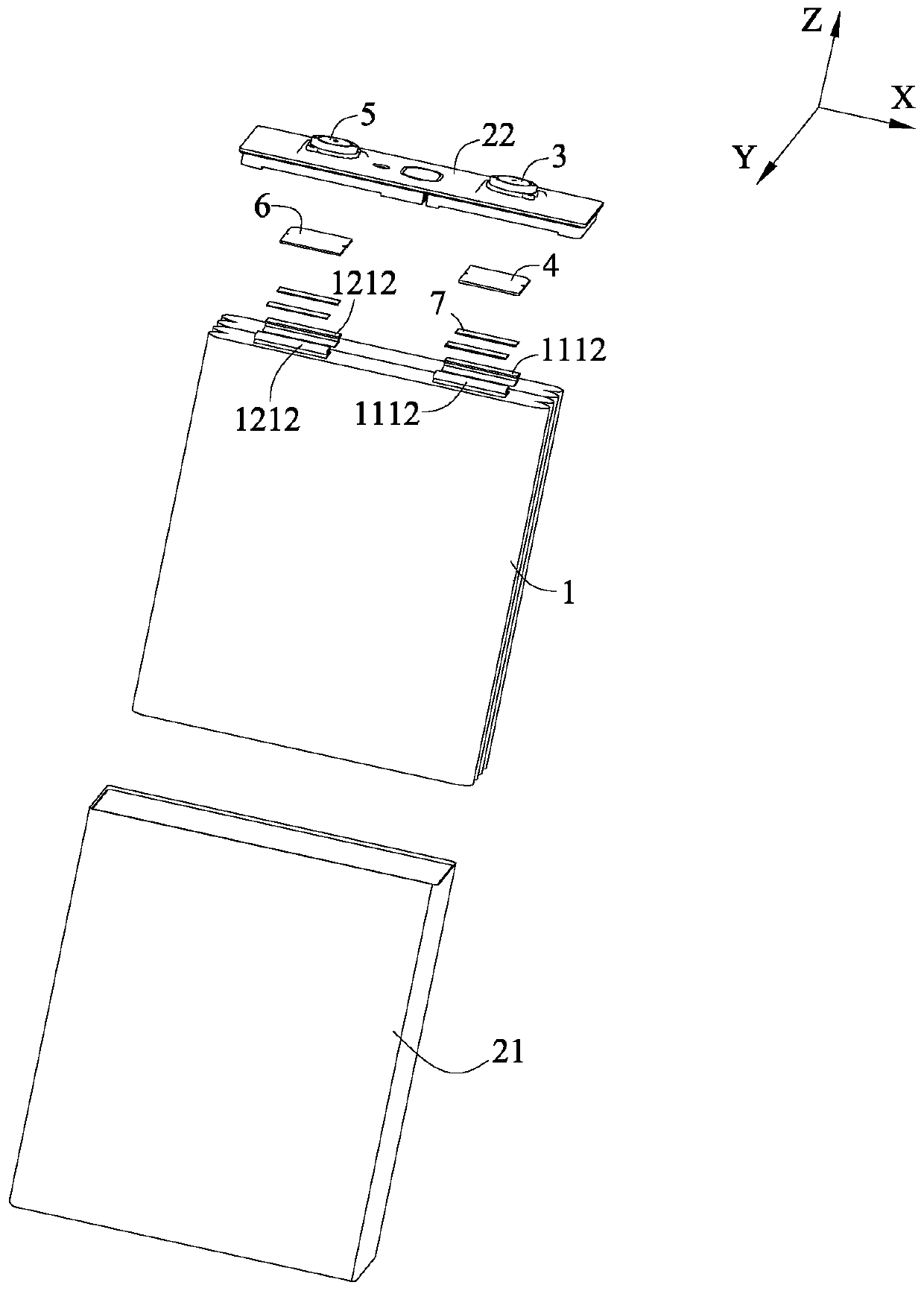

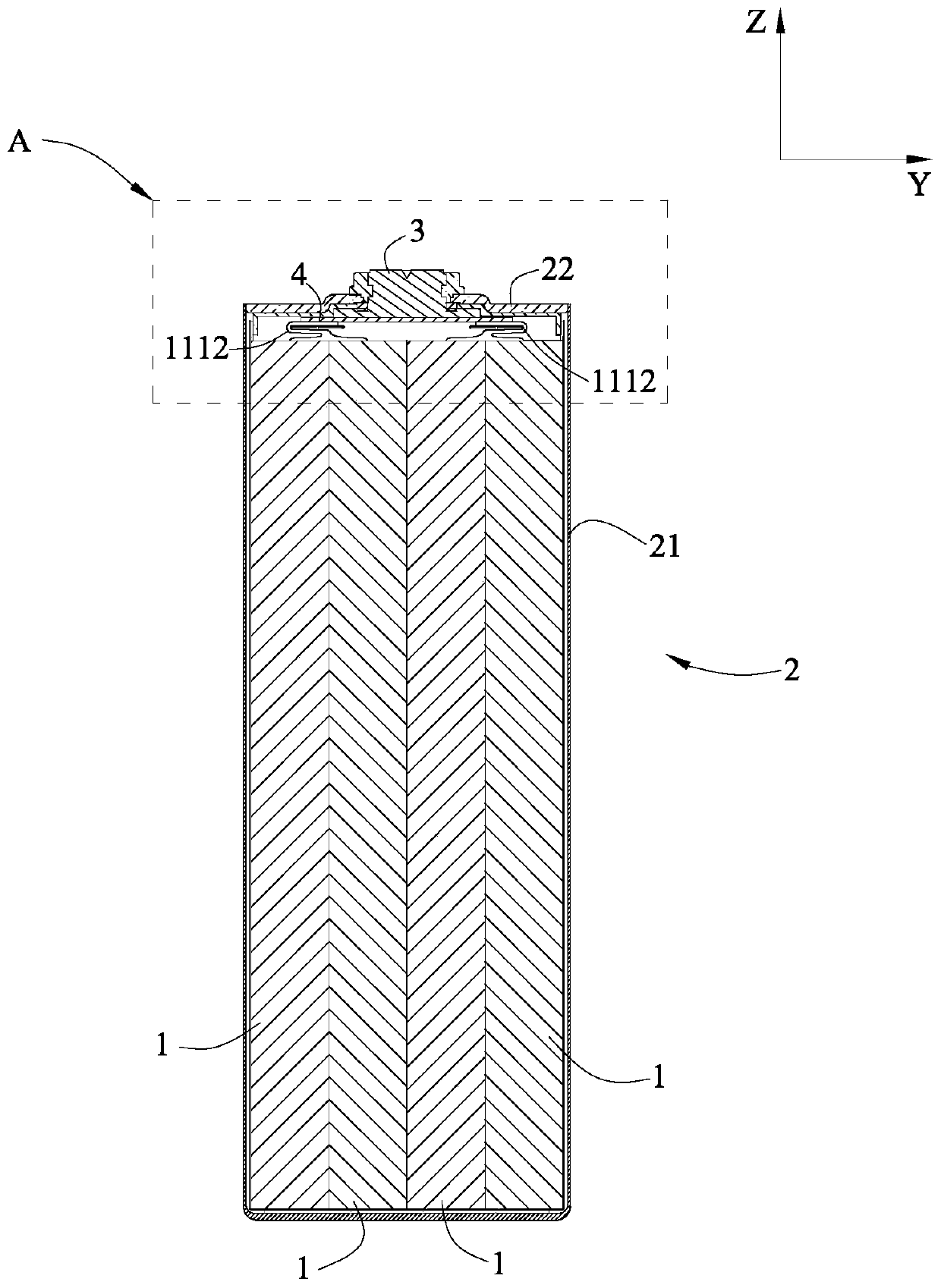

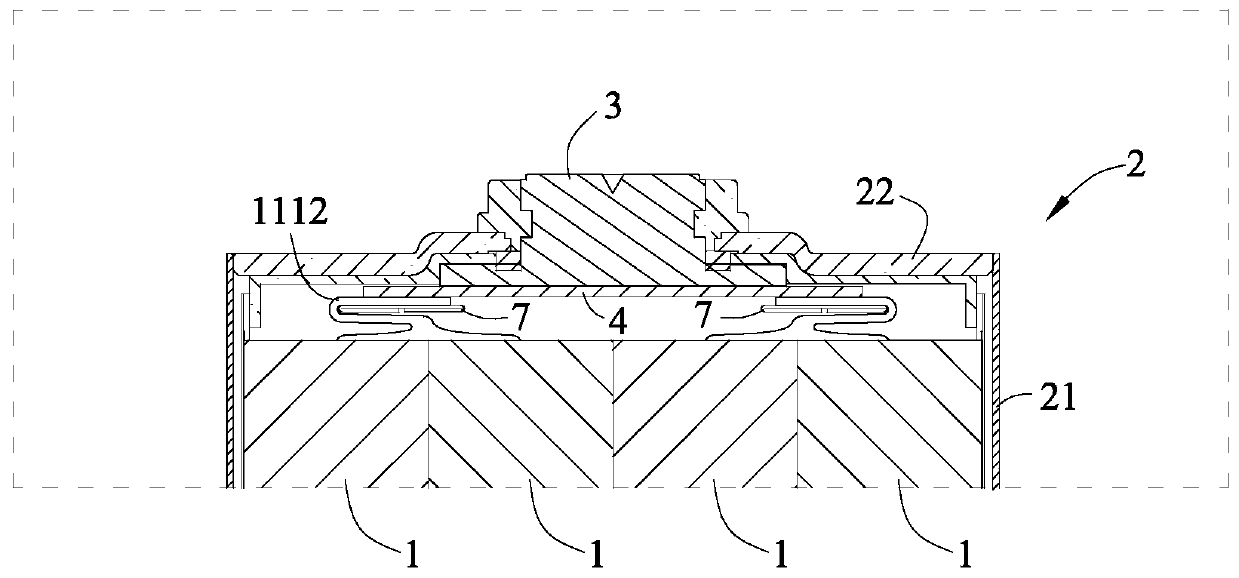

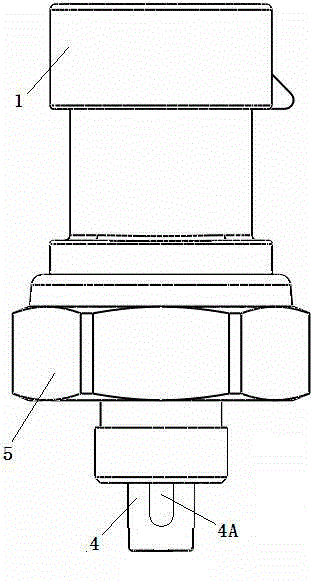

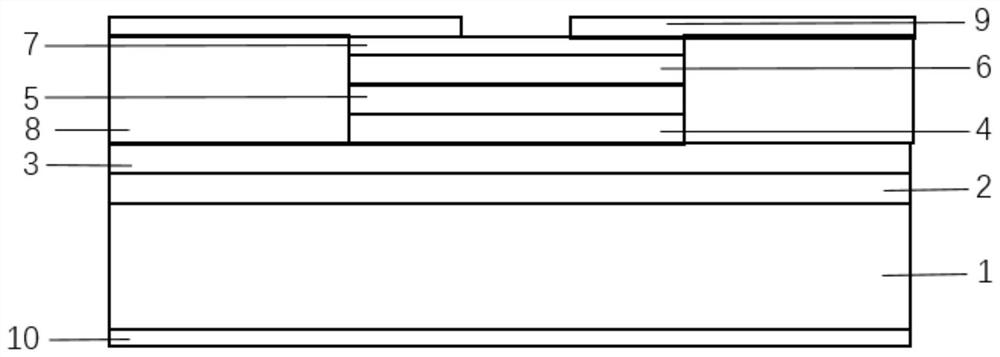

The invention provides a secondary battery, which includes an electrode assembly, a shell and a first electrode terminal, wherein the shell is provided with an accommodating cavity, the electrode assembly is accommodated in the accommodating cavity, and the first electrode terminal is arranged in the shell; the electrode assembly comprises a first pole piece, a second pole piece and a diaphragm, and the diaphragm separates the first pole piece from the second pole piece; the first pole piece comprises a first current collector, a first active substance layer and an insulating layer; the firstcurrent collector comprises a first main body part and a first tab extending from the first main body part, at least part of the surface of the first main body part is coated with the first active substance layer, and the first tab protrudes out of the first main body part and is electrically connected with the first electrode terminal; and the insulating layer is at least partially coated on thesurface of the first tab, and the elastic modulus of the insulating layer is less than that of the first tab.

Owner:CONTEMPORARY AMPEREX TECH CO

High-precision temperature and pressure sensor

InactiveCN105466483AReduce heat lossAccurate measurementMeasurement devicesTemperature stressEngineering

The present invention relates to a temperature and pressure sensor which comprises a terminal with pins, a TO assembly and a shell. The terminal and the shell are connected in a sealed way, and two sides of a sealed surface are provided with cavity in mutual communication. One end of the shell far from the terminal is provided with a through hole which is communicated with the cavities. The T0 assembly is arranged in the cavity and comprises a TO plate which seals the cavity opening in the shell, a PCB which is connected to the pins in the terminal, and a thermistor. The PCB is arranged at the top surface of the TO plate which is provided with a thermistor wire connection rod and a pressure measuring through hole. One end of the thermistor wire connection rod extends downward into the through hole and is connected to the thermistor, and the other end goes through the PCB and is connected to the PCB. The PCB is connected to a sensitive device which comprises a pressure chip. The pressure chip just faces the pressure measuring through hole and goes through the bottom of the pressure measuring through hole to seal the pressure measuring through hole. The temperature and pressure sensor has the advantages of high measurement accuracy, simple structure, easy processing, low cost, and small size.

Owner:WUHAN FINEMEMS

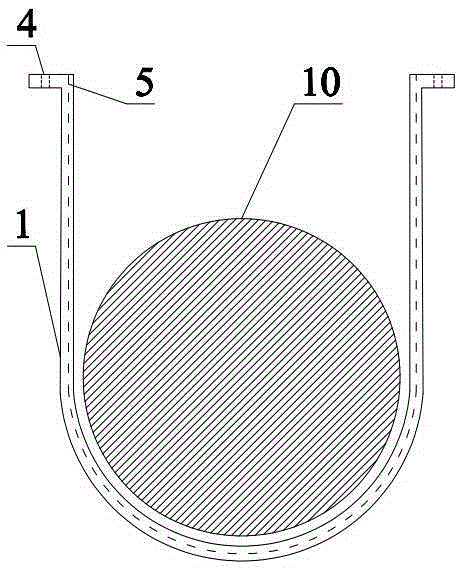

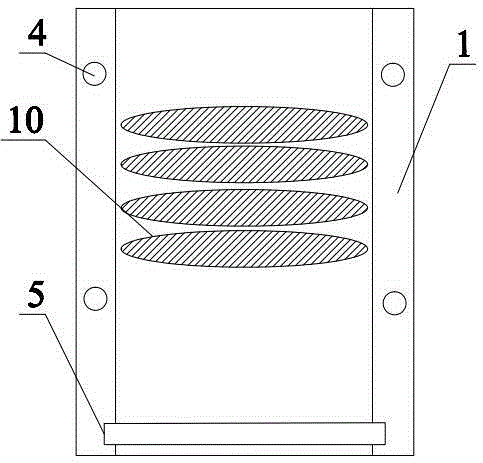

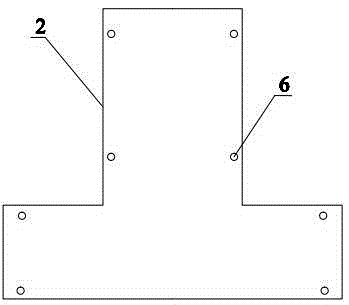

Electric power heat insulation type insulator insulation shielding cover

ActiveCN105356367AGuaranteed insulation effectEasy to installCoatingsApparatus for overhead lines/cablesWear resistantEngineering

The invention discloses an electric power heat insulation type insulator insulation shielding cover. The electric power heat insulation type insulator insulation shielding cover comprises an insulator shielding cover, a shielding cover covering plate, and a suspension clamp shielding cover, the insulator shielding cover is arranged in the U shape, edges of two side surfaces of the insulator shielding cover are provided with first fixing holes, the inner side of the lower part of the insulator shielding cover is provided with a base connecting groove, the insulator shielding cover is movably connected with the suspension clamp shielding cover via the base connecting groove, the shielding cover covering plate is arranged in the T shape, the shielding cover covering plate is provided with second fixing holes corresponding to the first fixing holes, the central part of the suspension clamp shielding cover is provided with a U-shaped metal shielding cover, the external surface of the metal shielding cover is provided with a U-shaped slipway, the inner part of the metal shielding cover is provided with wire clamp fixtures, and surfaces of the insulator shielding cover, the shielding cover covering plate, the suspension clamp shielding cover, and the metal shielding cover are all coated with high-temperature-resistant and wear-resistant insulation paints. According to the electric power heat insulation type insulator insulation shielding cover, the structure is simple, the operation is convenient, the shielding effect is good, and the safety factor is big.

Owner:国网河南省电力公司超高压公司 +1

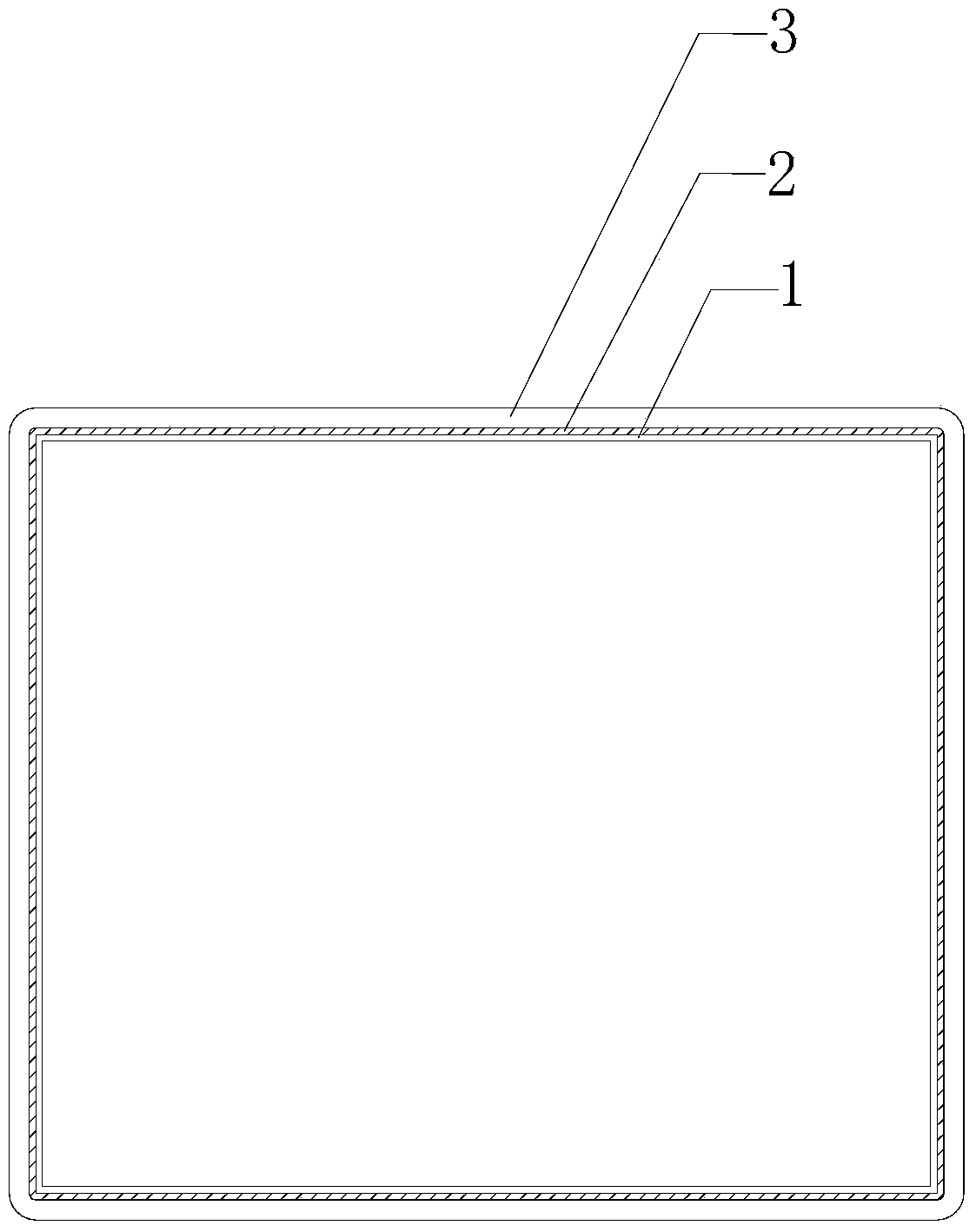

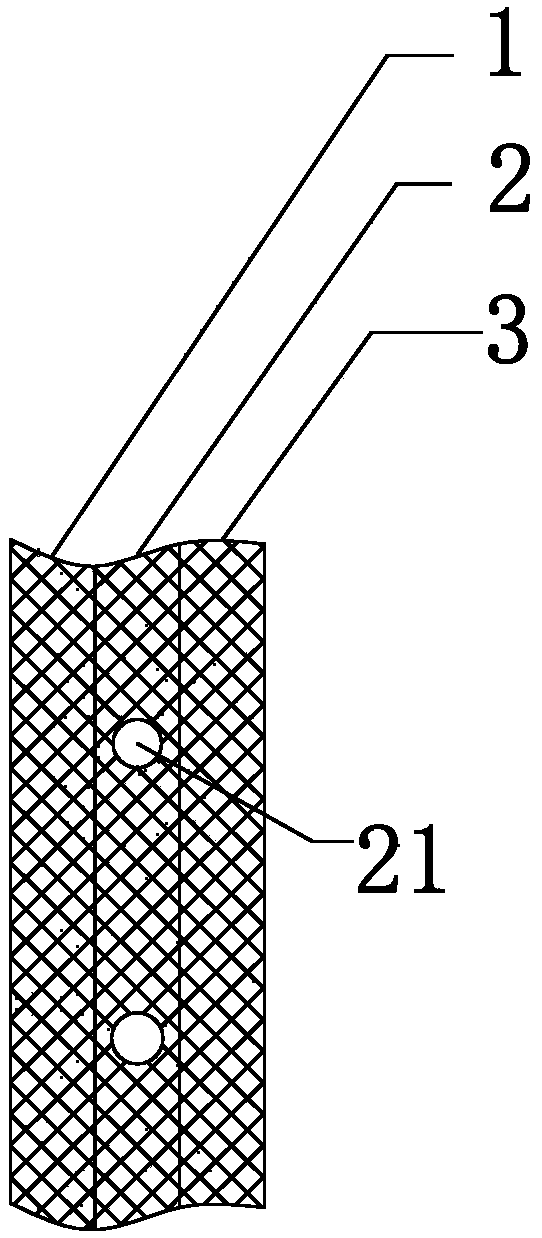

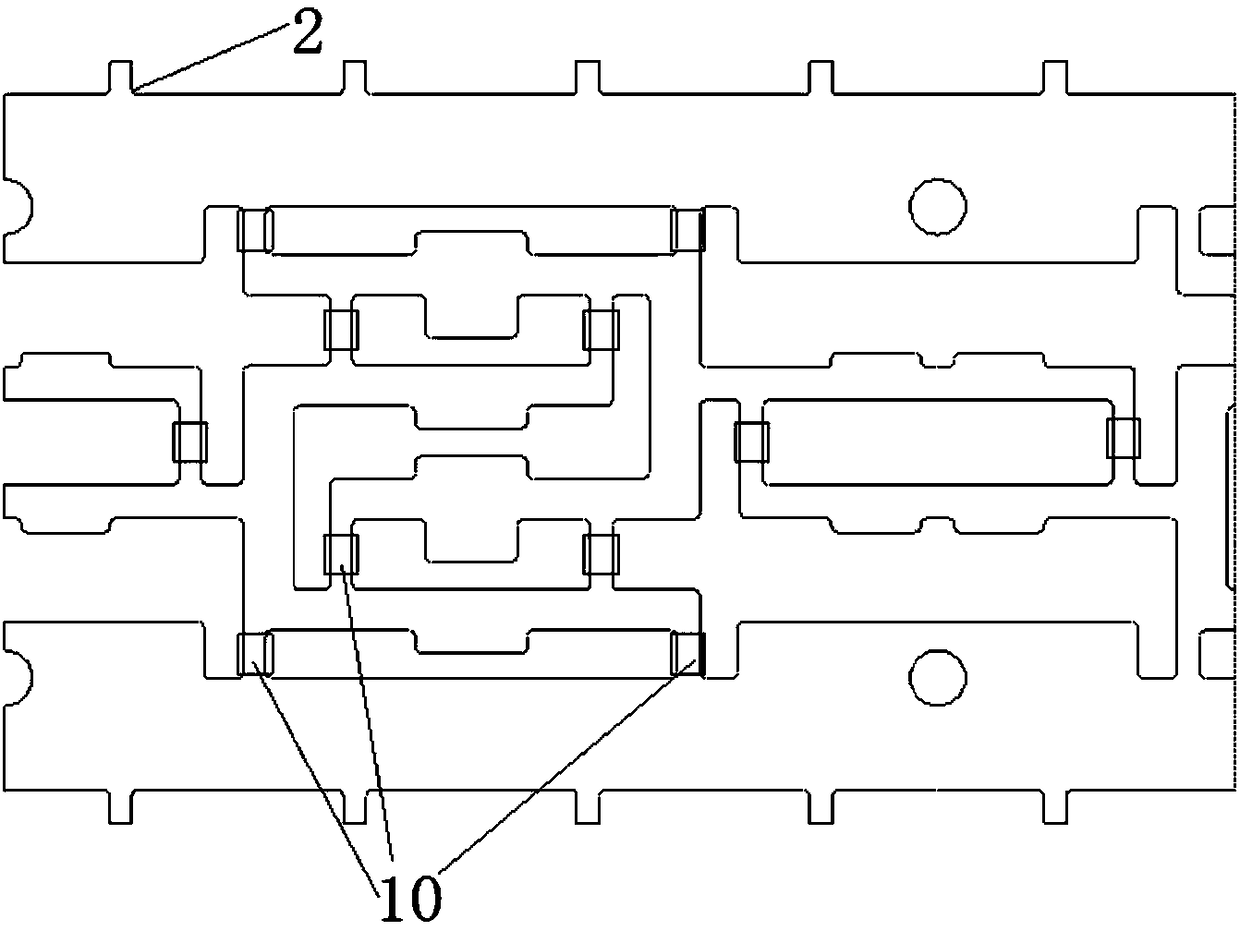

Lithium battery pack housing

ActiveCN103633263AImprove impact resistanceAvoid crackingSecondary cellsCell component detailsElectrical and Electronics engineeringMetal

The invention discloses a lithium battery pack housing which comprises a metal inner layer, wherein the outside of the metal inner layer is coated with an impact-resistant, insulating and heat-insulating three-dimensional mesh outer layer, and a heat exchange device which is used for carrying out heat exchange with outside to control the temperature inside a battery pack is arranged between the three-dimensional mesh outer layer and the metal inner layer. The lithium battery pack housing has the advantages that when the lithium battery pack is impacted and vibrated, the three-dimensional mesh outer layer can well absorb an external impact, so that the impact resistance of the housing is enhanced, and the impaction can not be directly transmitted to the inside of the lithium battery pack; the outside of the metal inner layer is coated with the three-dimensional mesh outer layer so that the metal inner layer can be prevented from cracking to play a role of insulation protection.

Owner:SUZHOU ANKAO ENERGY

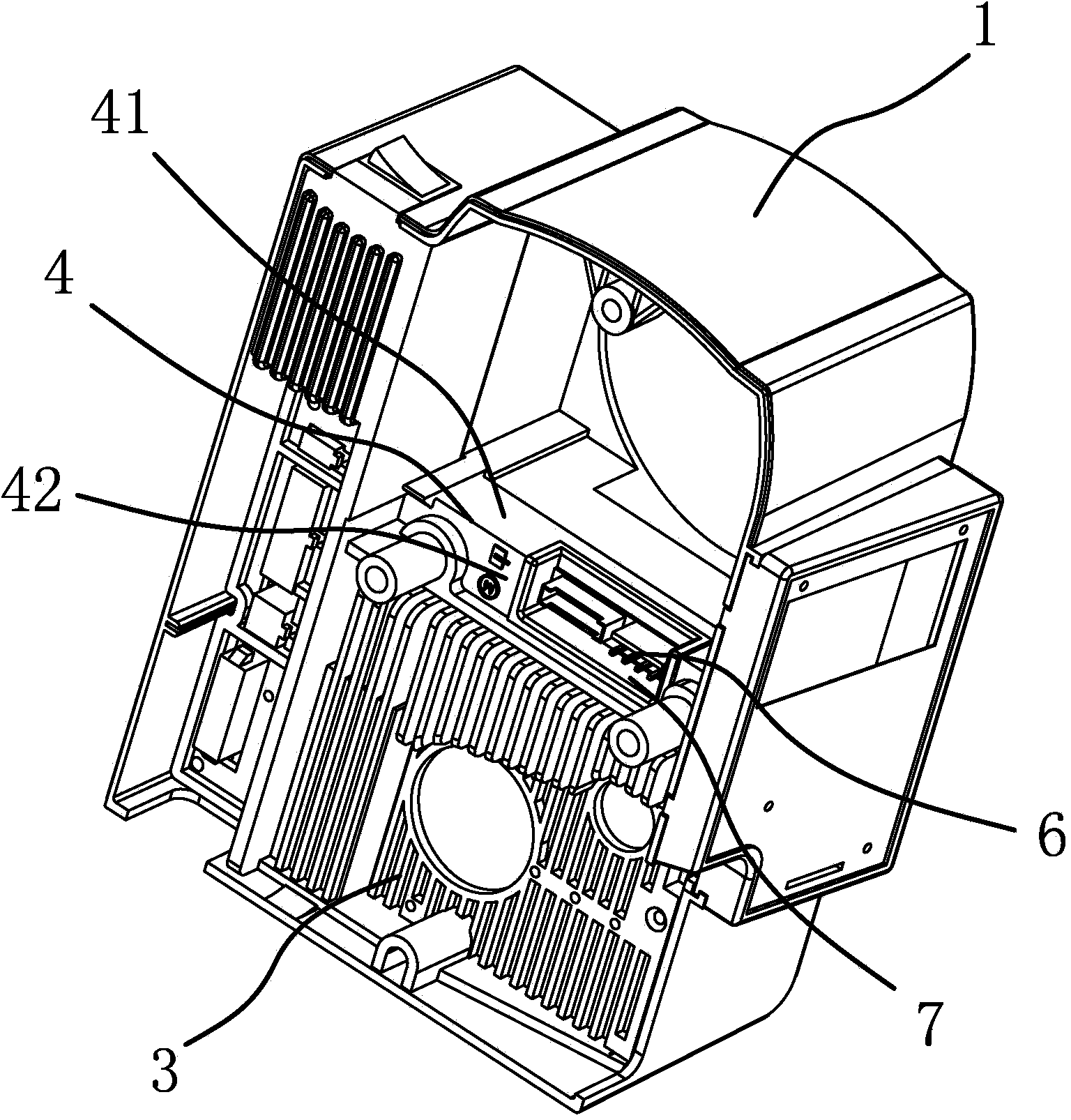

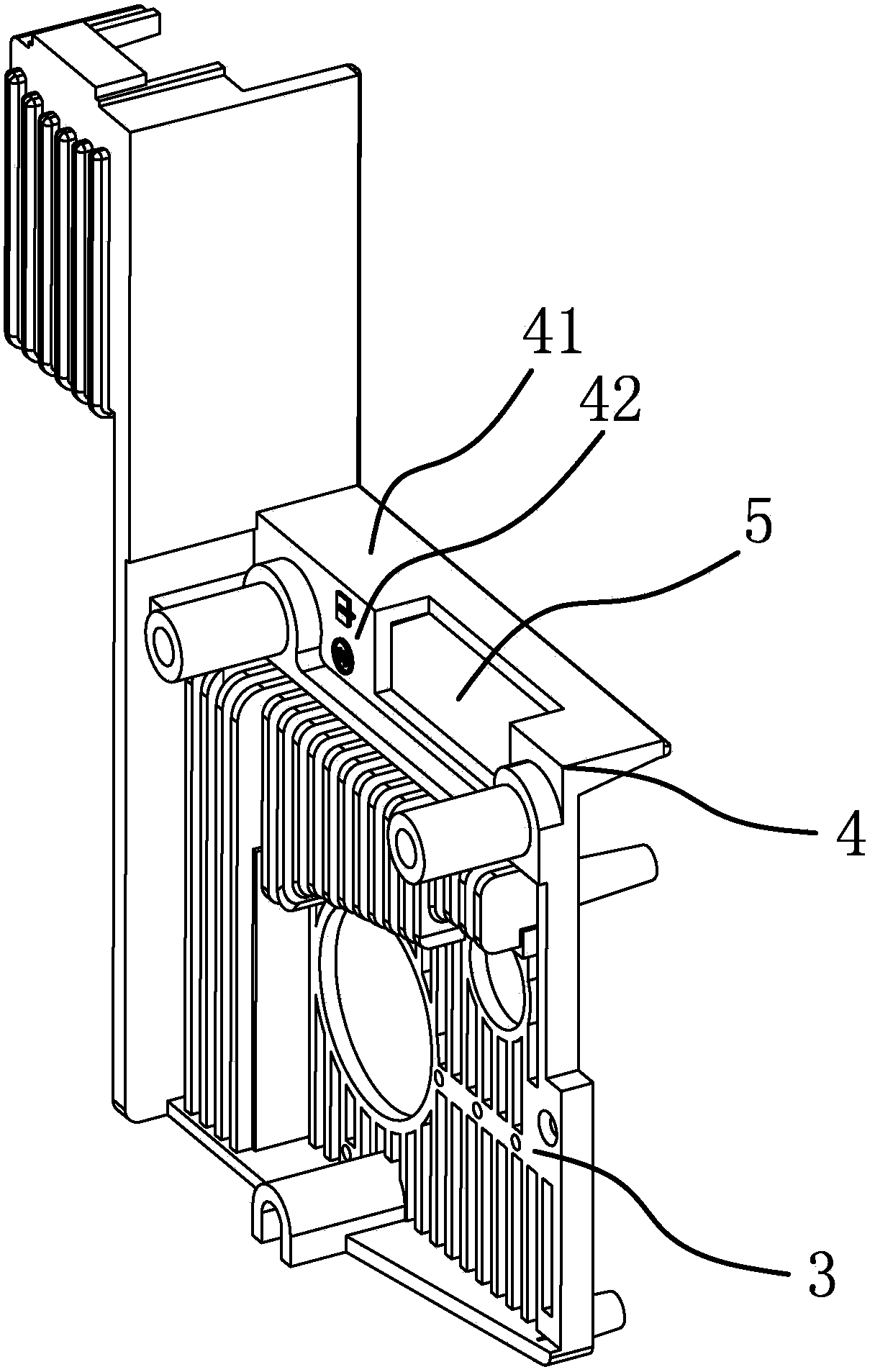

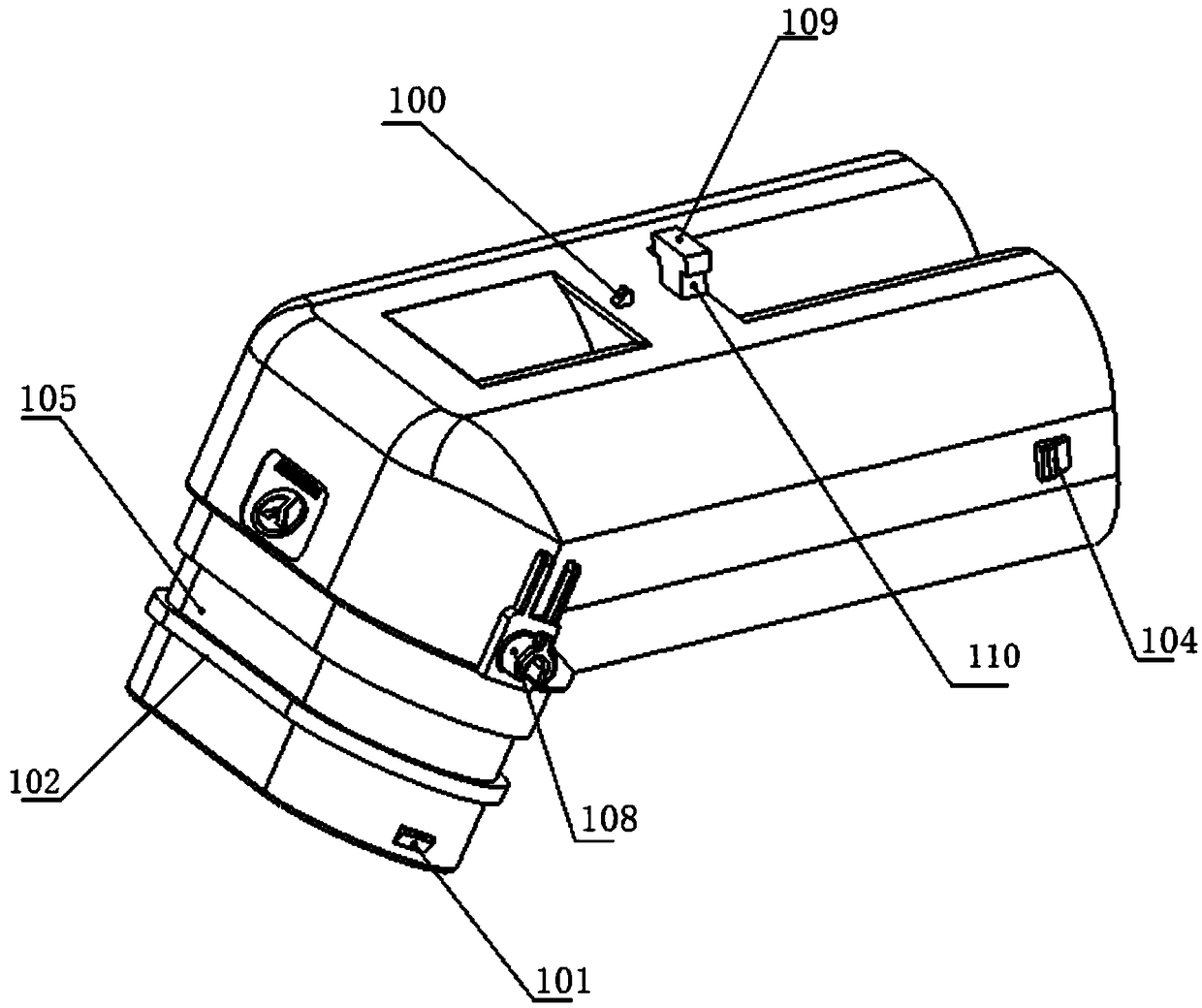

Connecting structure for motor and circuit board in flat sewing machine control device

ActiveCN104389121ASimple connectionImprove installation efficiencySewing-machine control devicesEngineeringSewing machine

The invention provides a connecting structure for a motor and a circuit board in a flat sewing machine control device and belongs to the technical field of sewing machines. The connecting structure solves the problems of complicated connection between the motor and the circuit board, and the like at present. According to the connecting structure for the motor and the circuit board in the flat sewing machine control device, the control device comprises a housing internally provided with a cavity, the circuit board and a heat-dissipation aluminum plate, wherein the circuit board is fixed at the lower part of the cavity of the housing via the heat-dissipation aluminum plate. The connecting structure comprises a connecting plate at the top of the heat-dissipation aluminum plate, wherein a connector is arranged on the connecting plate, and a motor socket is arranged at the top of the circuit board and located in the connector. The connecting structure for the motor and the circuit board has the advantage of high mounting efficiency for connecting the motor and the circuit board.

Owner:QIXING INTELLIGENT TECH CO LTD

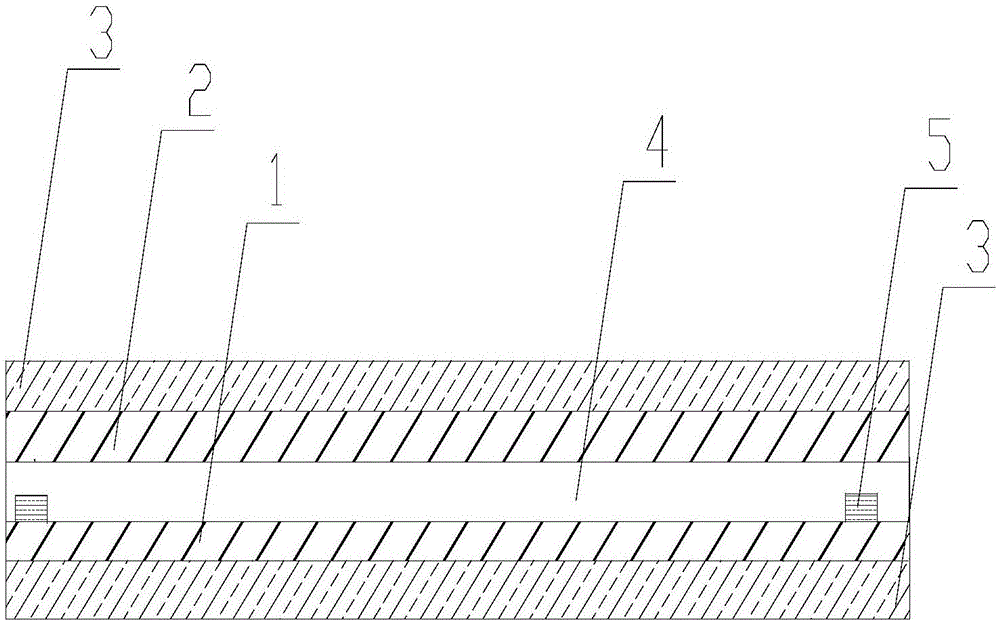

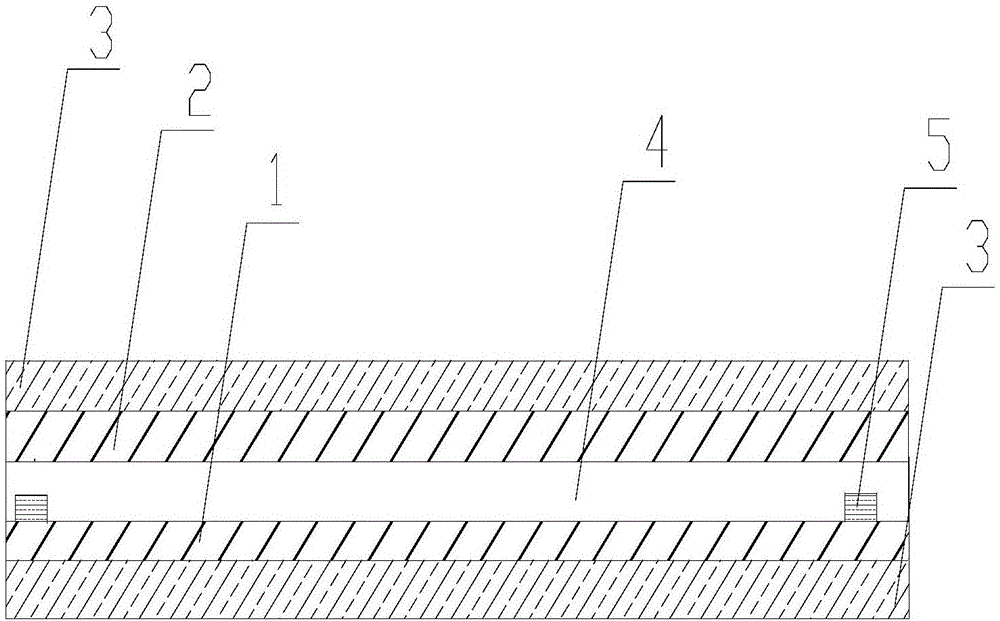

Flame-retardant carbon crystal heating plate and preparation method thereof

InactiveCN106162957AImprove the effect of hot pressingImprove securityHeating element materialsGraphite carbonHeat resistance

The invention discloses a flame-retardant carbon crystal heating plate which is prepared by the following steps: 1) fixing one end of a copper bar on the front of a first resin layer, and extending the other end to the outside of the first resin layer; 2) brushing graphite carbon slurry on the front of the first resin layer to form a graphite layer, and coating one end of the copper bar in the graphite carbon slurry; 3) hot pressing a second resin layer on the graphite layer to obtain a sandwich plate; and 4) hot pressing mica paper on both sides of the sandwich plate, and naturally cooling to obtain the flame-retardant carbon crystal heating plate. The flame-retardant carbon crystal heating plate has the advantages of long-time uniform heating, high-pressure resistance, good heat resistance and safety in use.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

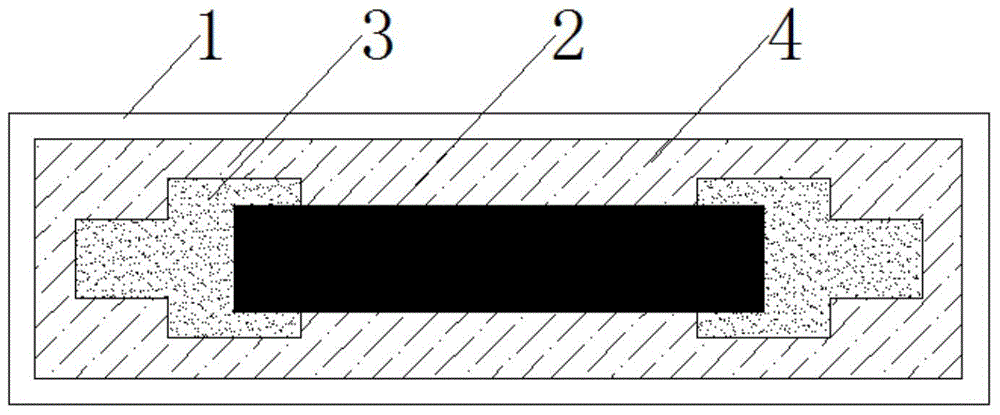

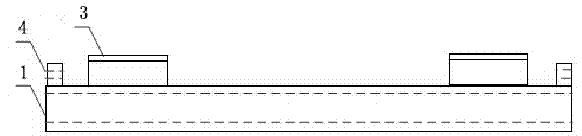

Strain test sensing element with matched modulus and manufacturing method thereof

InactiveCN104913718ASimple structureEasy to makeElectrical/magnetic solid deformation measurementElectricityRubber material

The invention, which belongs to the field of the test sensing element and the manufacturing method thereof, provides a strain test sensing element with matched modulus and a manufacturing method thereof. The sensing element comprises a thin plate arranged at a bottom layer, a sensitive thin film arranged at an intermediate layer, electrodes arranged at the intermediate layer, and an insulating protection film arranged at a top layer. The thin plate arranged at the bottom layer is a plastic or rubber thin plate and is selected and determined based on the modulus of a strain test object. According to the sensitive thin film and the electrodes that are arranged at the intermediate layer, the electrodes are arranged at the two ends of the sensitive thin film; and the sensitive thin film is formed by printing of a conductive macromolecule composite material and the electrodes are formed by printing of conductive silver pastes. The insulating protection film arranged at the top layer is formed by printing of a resin or rubber material. The thin plate at the bottom layer, the sensitive thin film and the electrodes at the intermediate layer, and the insulating protection film at the top layer are selected according to the modulus of the tested object, thereby realizing modulus matching; and then a strain test sensing element is manufactured. Synchronous strain of the sensing element and the tested object can be realized well; the tested strain value becomes accurate; the testing range can be met well; and the test precision is improved. Moreover, the cost is low and the effect is good on the condition of batch production.

Owner:CHINA UNIV OF MINING & TECH

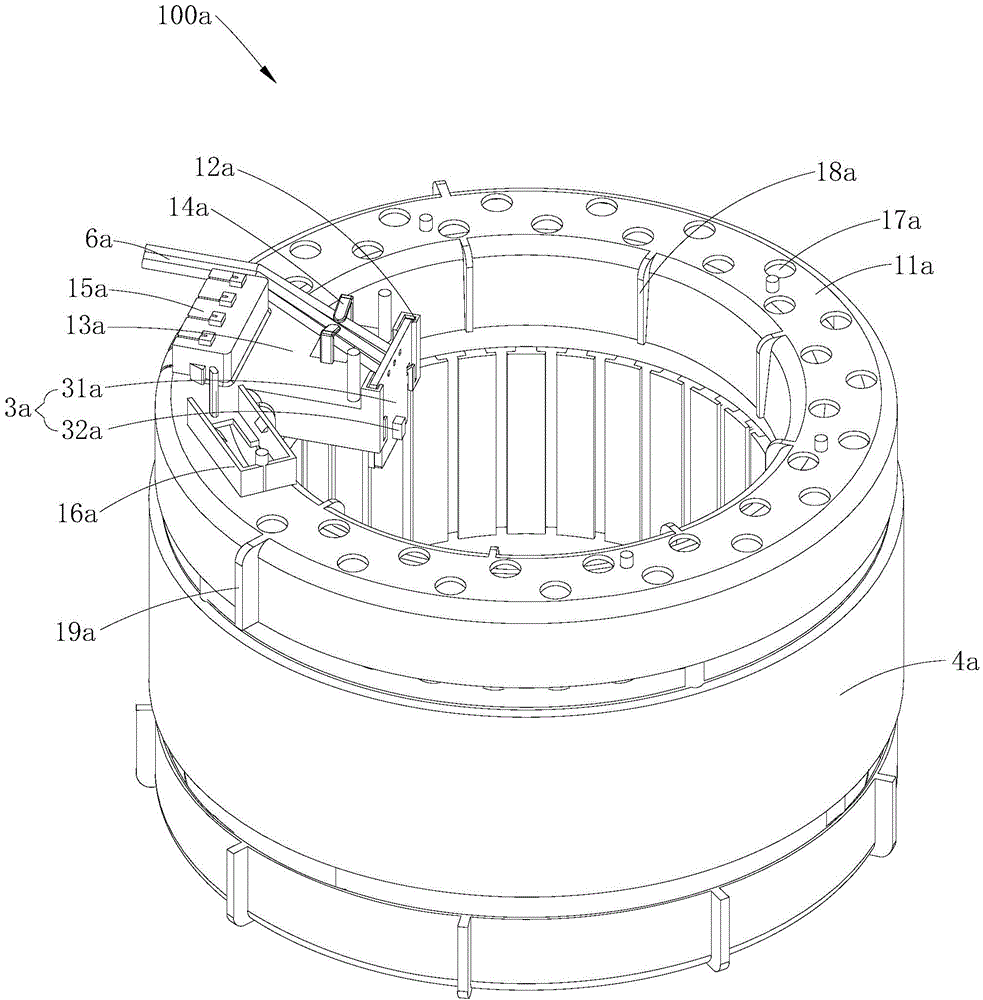

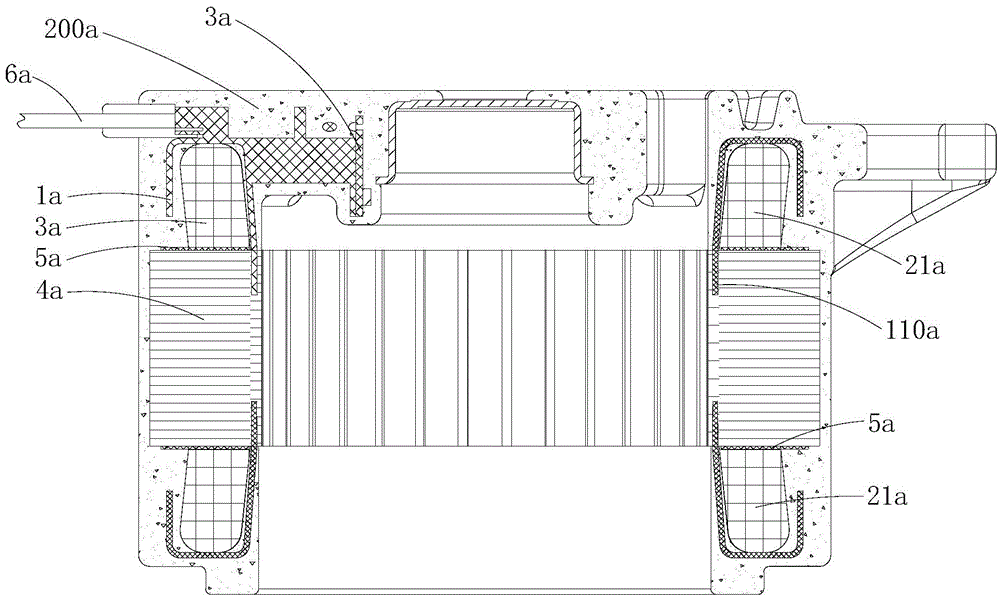

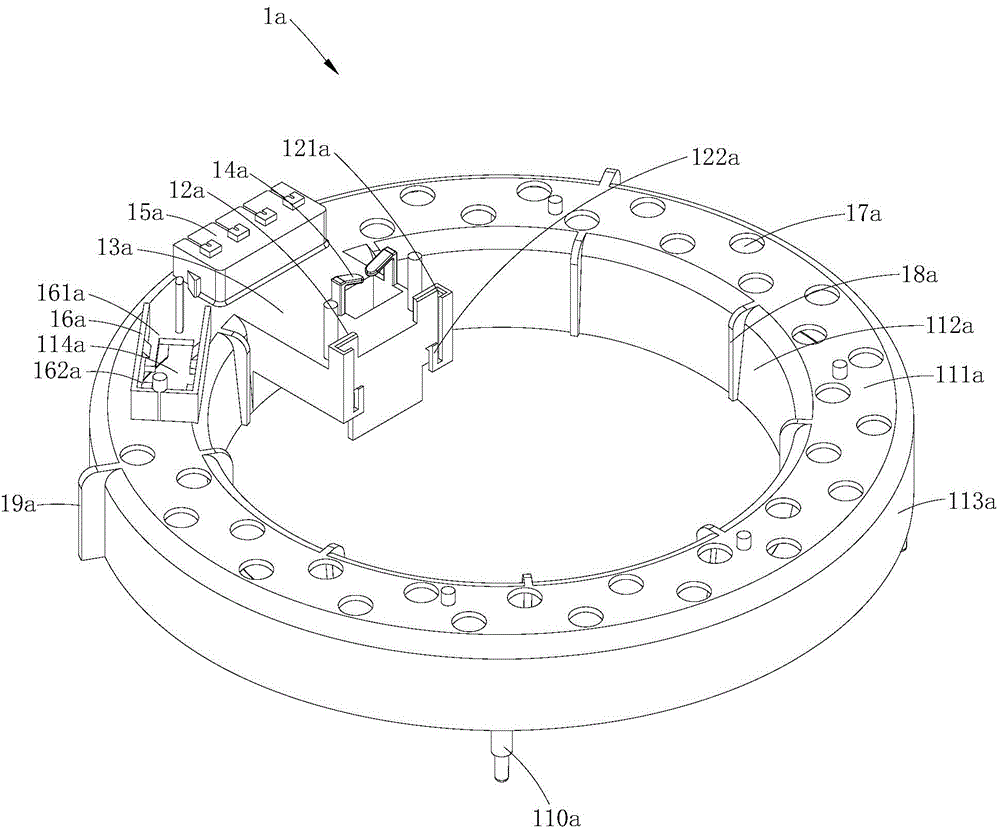

Stator winding end insulation frame, plastic-packaging stator assembly, and plastic-packaging motor

ActiveCN104836358AAutomate installationGuaranteed reliabilityWindings insulation shape/form/constructionPlastic packagingEngineering

The invention is suitable for the field of motors, and discloses a stator winding end insulation frame, a plastic-packaging stator assembly, and a plastic-packaging motor. The insulation frame comprises an insulation frame body which is disposed at an axial end part of a stator winding along the axial direction of a motor in a sleeve manner. The insulation frame body is provided with a PG plate installation frame which is used for the installation and positioning of a PG plate member, wherein the PG plate installation frame is provided with a clamping groove which is used for the storage and positioning of the PG plate member. According to the invention, the insulation frame body is additionally provided with the PG plate installation frame, thereby achieving the installation and positioning of the PG plate member only if the PG plate member is slidingly clamped and inserted in the clamping groove of the PG plate installation frame during installation. The installation is very convenient, thereby facilitating the implementation of the automatic installation of the PG plate installation frame. Moreover, the PG plate member cannot be damaged by pressing in an installation process, thereby guaranteeing the reliability of motor performances. Meanwhile, the reduction design of the PG plate member is also facilitated, thereby avoiding the material waste, and reducing the cost of a motor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

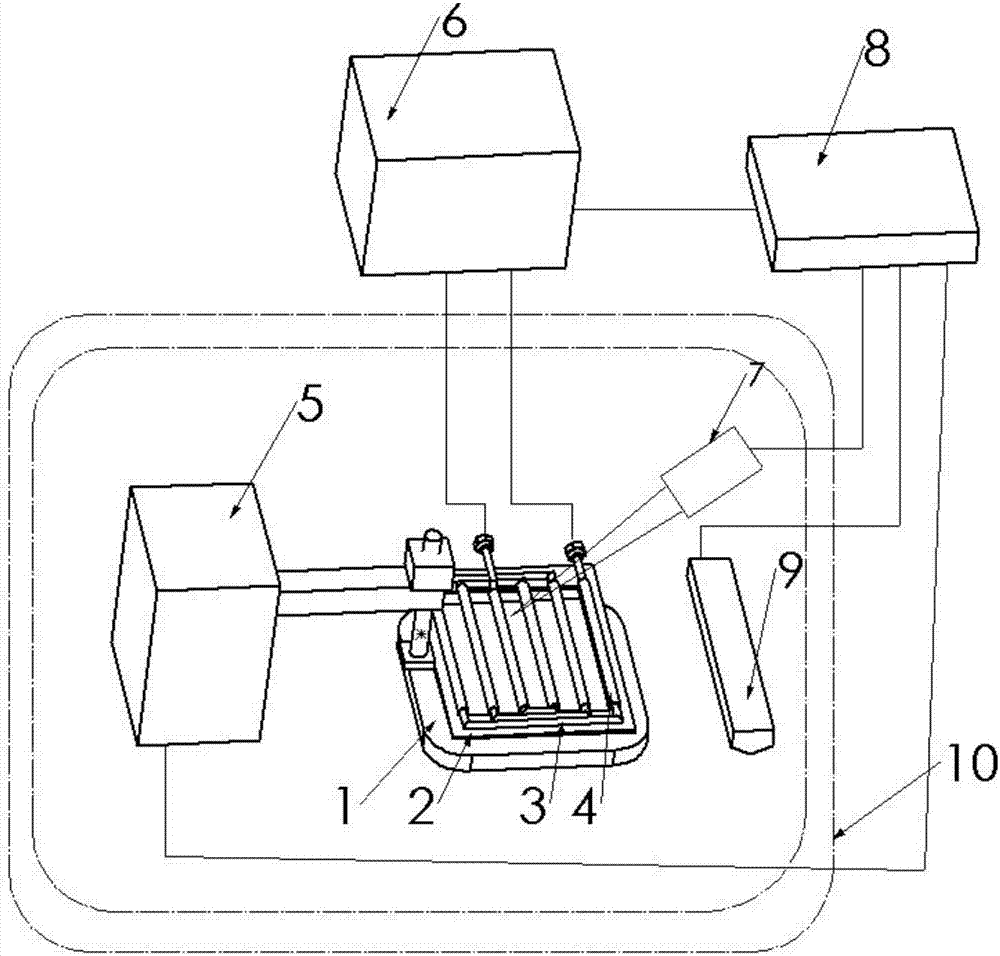

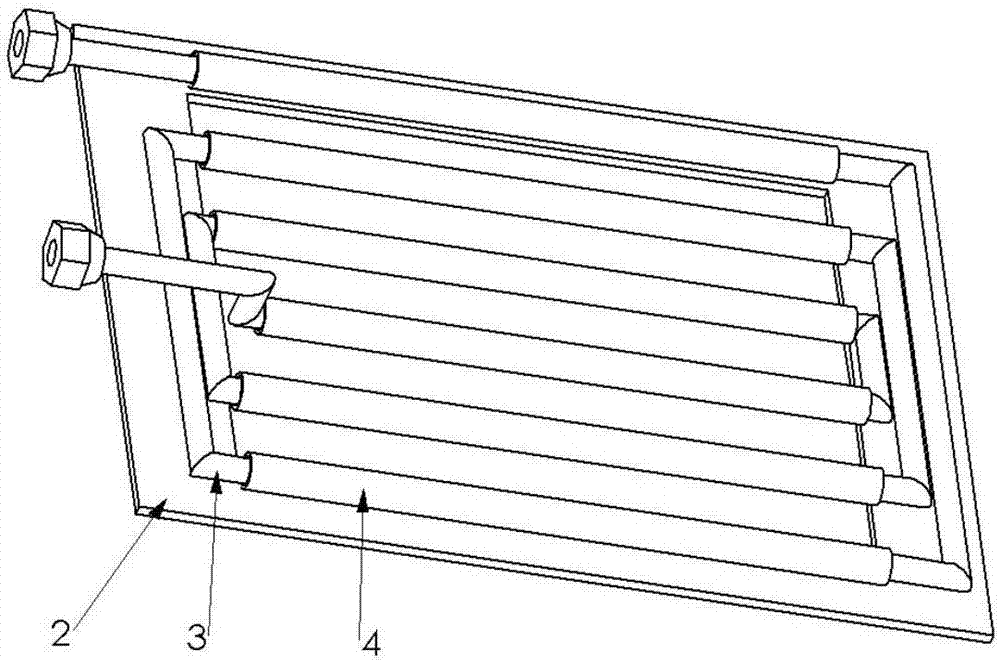

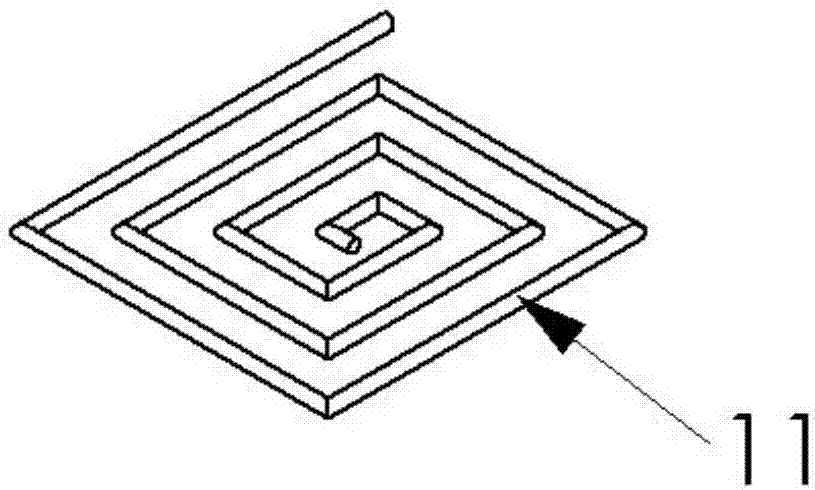

Electromagnetic induction selective laser melting powder bed on-line heating system and method

InactiveCN106903311AGuaranteed continuous heatingRealize online annealingManufacturing heating elementsIncreasing energy efficiencySelective laser meltingIntermediate frequency

The invention discloses an electromagnetic induction selective laser melting powder bed on-line heating system and an electromagnetic induction selective laser melting powder bed on-line heating method. The system comprises a powder bed in a selective laser melting forming chamber; a metal electromagnetic induction coil is arranged above the powder bed, and is connected with an intermediate-frequency or high-frequency heating power supply; the intermediate-frequency or high-frequency heating power supply is connected with a central control unit through a control circuit; the metal electromagnetic induction coil is fixed to a nonmetal high-temperature resistant bracket; the nonmetal high-temperature resistant bracket is connected with a three-dimensional moving bracket; the three-dimensional moving bracket is fixed in the selective laser melting forming chamber; an infrared thermometer is arranged above the metal electromagnetic induction coil; the powder bed is provided with a moving powder spraying device matched with the powder bed to move; and the three-dimensional moving bracket, the infrared thermometer and the moving powder spraying device are connected with the central control unit through the control circuit. With the adoption of the method, on-line heating on the surface of the powder bed can be realized, so a temperature gradient of a forming area is reduced, when the heating temperature is high enough, and on-line annealing on a manufactured part can be realized in an SLM forming process when a heating temperature is high enough.

Owner:XI AN JIAOTONG UNIV +1

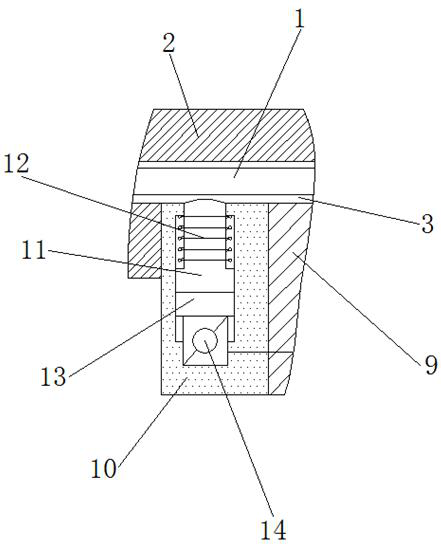

Manufacturing method of lamp strip

InactiveCN108361573ASmooth layoutReduce recyclingElectric lightingSemiconductor devices for light sourcesMetal stripsManufacturing technology

The invention relates to a manufacturing method of a lamp strip. The manufacturing method comprises the steps that a conductive metal strip capable of bending is wholly stamped into a circuit base strip, and the circuit base strip is provided with a plurality of circuit strips; each circuit strip is provided with a first power circuit, a second power circuit and an element circuit, and each element circuit is provided with a plurality of lamp bead mounting areas arranged in an M*N array mode; lamp beads are mounted at the lamp bead mounting areas in a pasted mode through soldering; transparentinsulating films are injected and molded on the entire outer surfaces of the element circuits and the lamp beads and the partial outer surfaces of the first power circuit and the second power circuitcorrespondingly; areas, not wrapped with the transparent insulating films, of the first power circuit and the second power circuit serve as a positive pole connecting area and a negative pole connecting area, and by adopting a connecting mode that M lamp beads are connected in parallel and then N sets of lamp bead sets composed of the M lamp beads are connected in series, disconnecting is conducted at the corresponding positions at the element circuits in a stamping work procedure; and the circuit strips are cut and separated, and manufacturing of the lamp strip is completed. By adopting themanufacturing method, the effects that printed circuits are not needed, the manufacturing technology is simple, pollution is less, and the cost is low can be achieved.

Owner:杭州小太阳农业科技有限公司

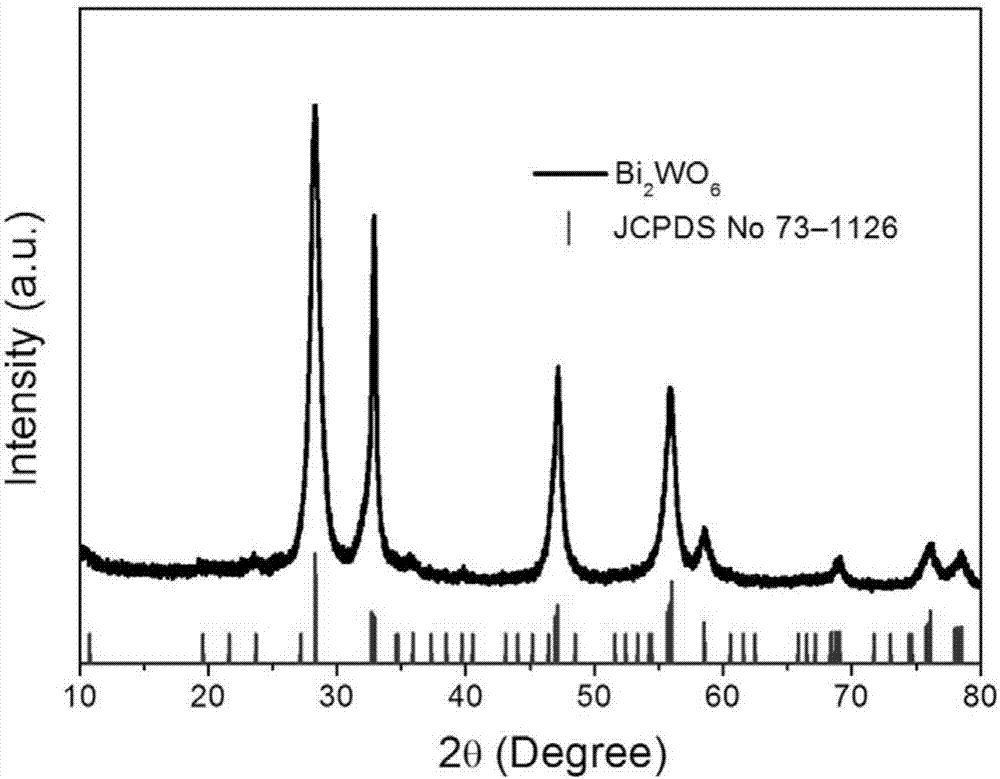

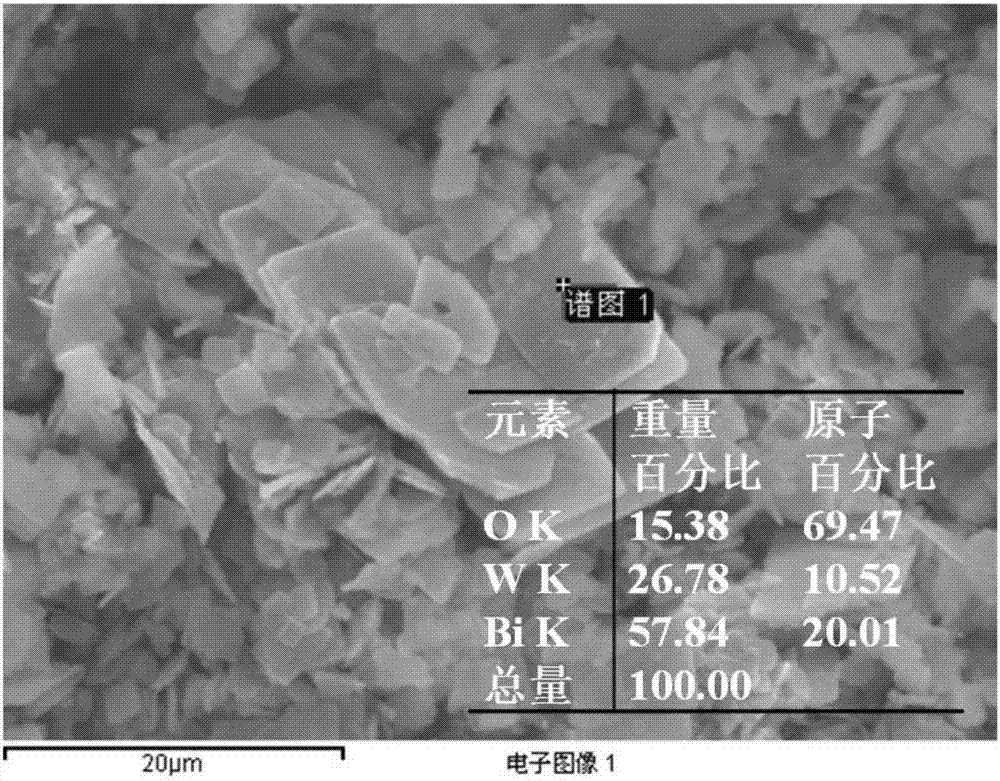

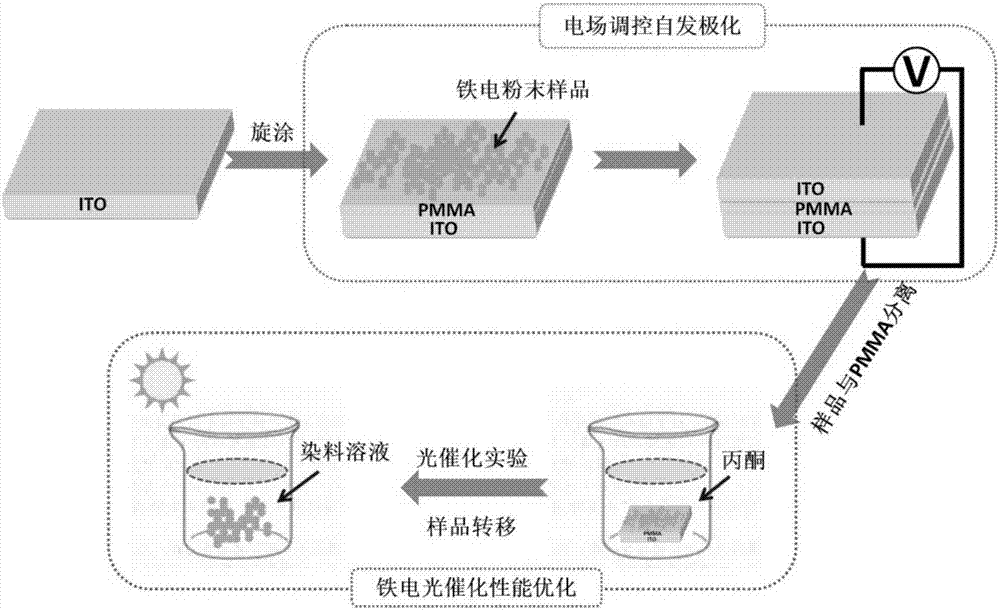

Method for enhancing photocatalysis performance of ferroelectric material through regulation and control of spontaneous polarization

ActiveCN107042105AImprove photocatalytic performanceGuaranteed decentralizationCatalyst carriersWater/sewage treatment by irradiationIntrinsic polarizationMolecular materials

The invention relates to a method for enhancing photocatalysis performance of a ferroelectric material through regulation and control of spontaneous polarization, an insulation film is prepared by employing soluble high-molecular material-loaded ferroelectric material powder, spontaneous polarization intensity of the ferroelectric material can be adjusted by an applied electric field, photo-induced electron and cavity are effectively separated under effect of intrinsic polarization field, life of a photon-generated carrier is prolonged, so that a purpose of enhancing photocatalysis performance of the material can be achieved. Compared with the prior art, the method provides the simple and effective approach for enhancing the photocatalysis performance of the ferroelectric material (especially the ferroelectric powder material).

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

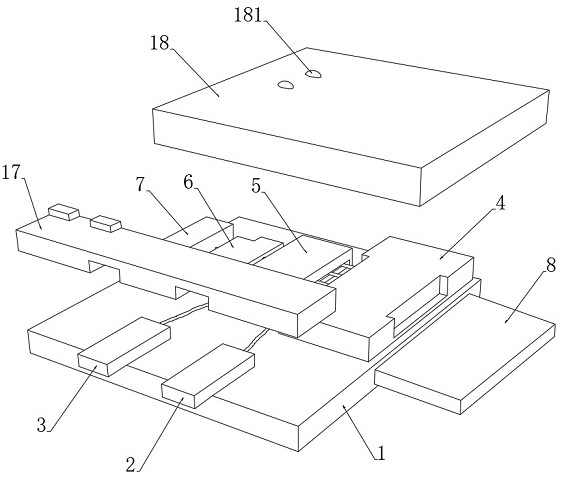

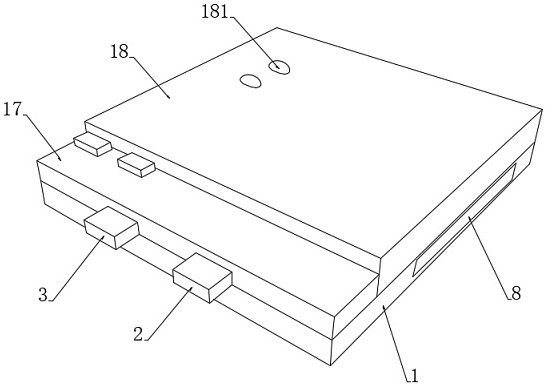

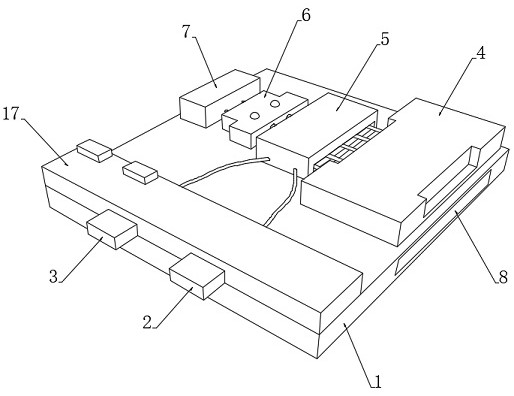

Portable electrical variable detection equipment with quick plug

ActiveCN112462102ARealize flexible plugging and unpluggingPlay a buffering effectCurrent/voltage measurementMeasurement instrument housingEmbedded systemElectrical current

The invention discloses portable electrical variable detection equipment with a quick plug, which belongs to the technical field of electrical variable detection, and is characterized in that the quick plug used for being connected with a current detection sensor and a voltage detection sensor is arranged on the detection equipment and consists of a mother joint and a son joint which are correspondingly arranged; the flexible electromagnet on the mother connector is used for magnetically attracting the flexible auxiliary magnet on the son connector after being started, rapid connection betweenthe son connector and the mother connector is achieved, the current detection sensor and the voltage detection sensor are used for detecting current and voltage, detection results are transmitted tothe flat plate, the flat plate is stored in the detection plate, carrying is convenient, and when the flexible electromagnet is disconnected, the quick plug can be disconnected, a port does not need to be manually replaced for testing, flexible plugging of the quick plug is effectively achieved through cooperation of the flexible electromagnet and the flexible auxiliary magnet, and the situation that the service life of the quick plug is shortened after the child connector and the mother connector are repeatedly plugged and unplugged is avoided.

Owner:CHANGSHA GUOTONG ELECTRICAL TECH

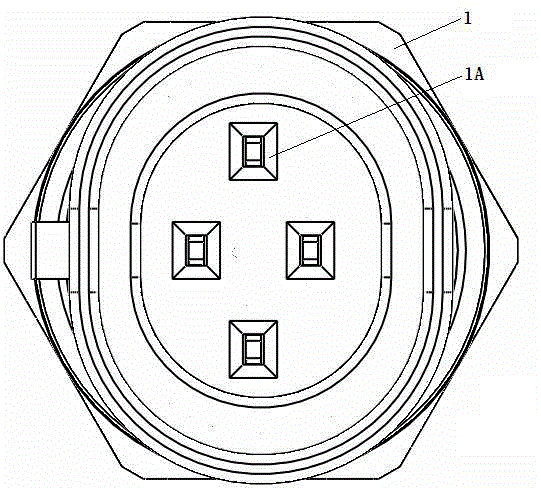

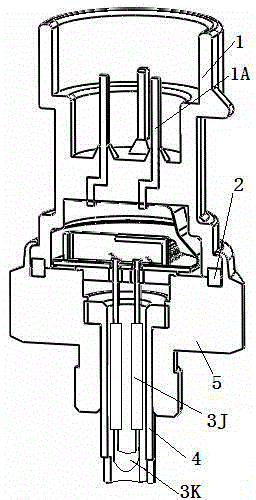

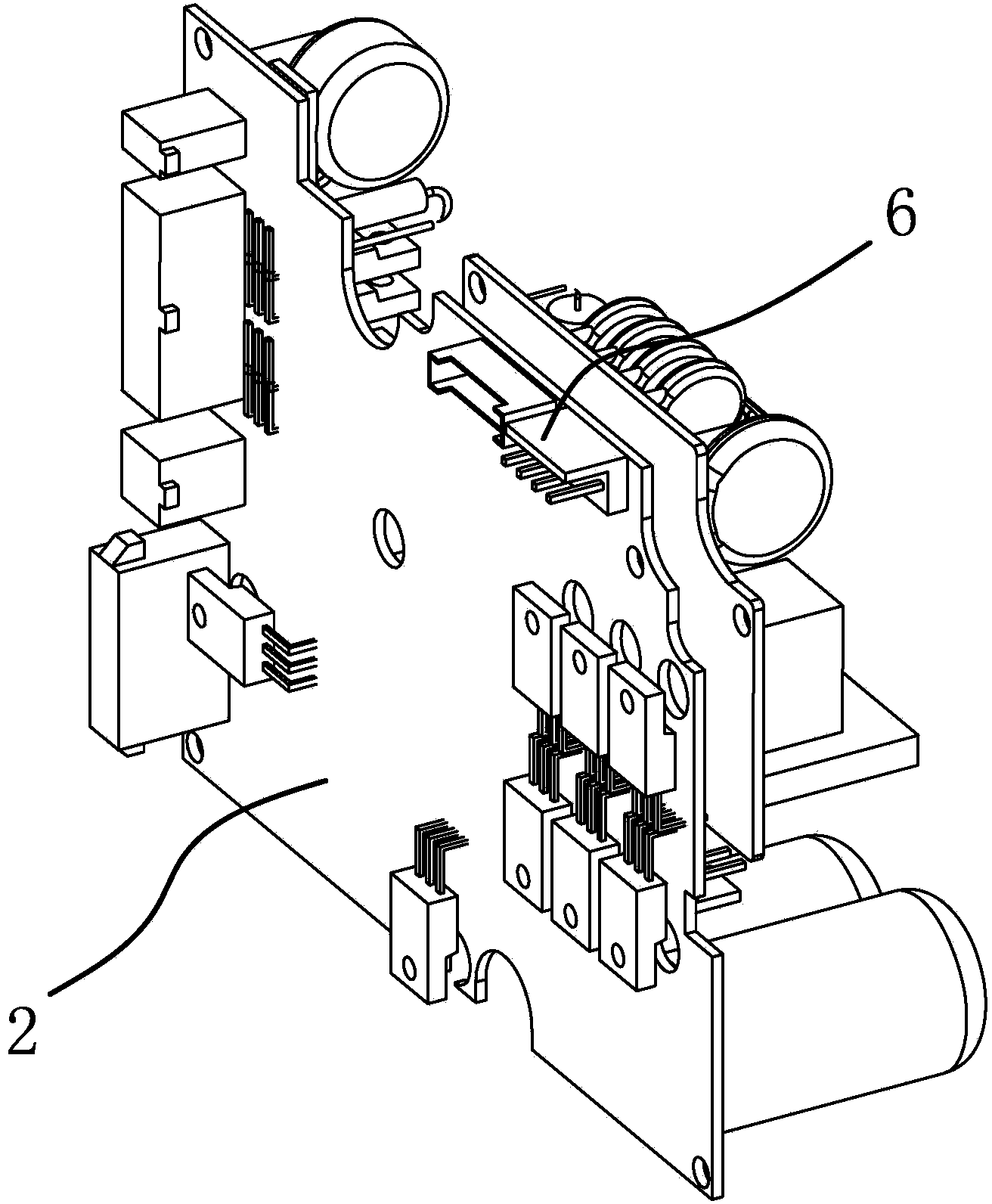

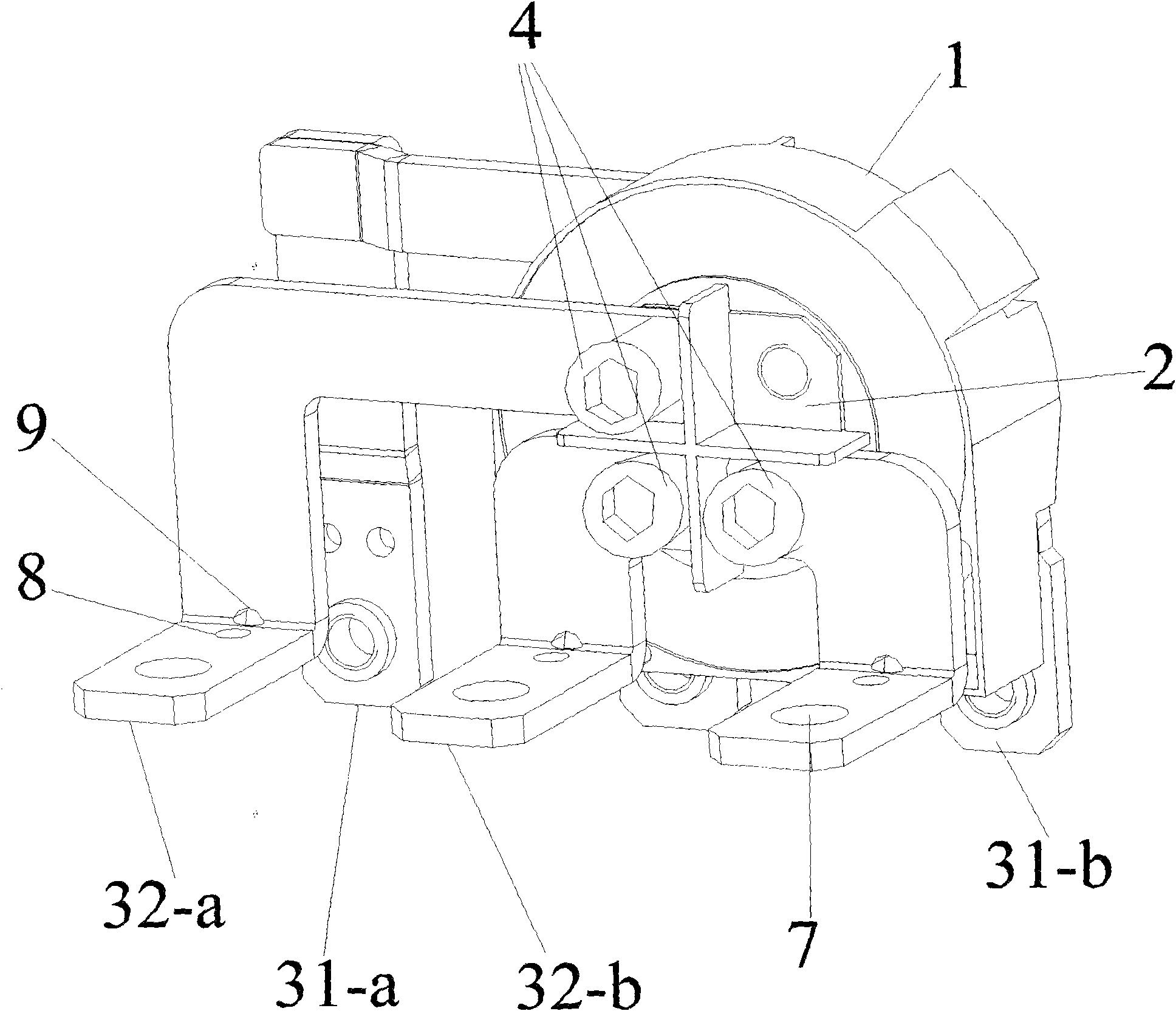

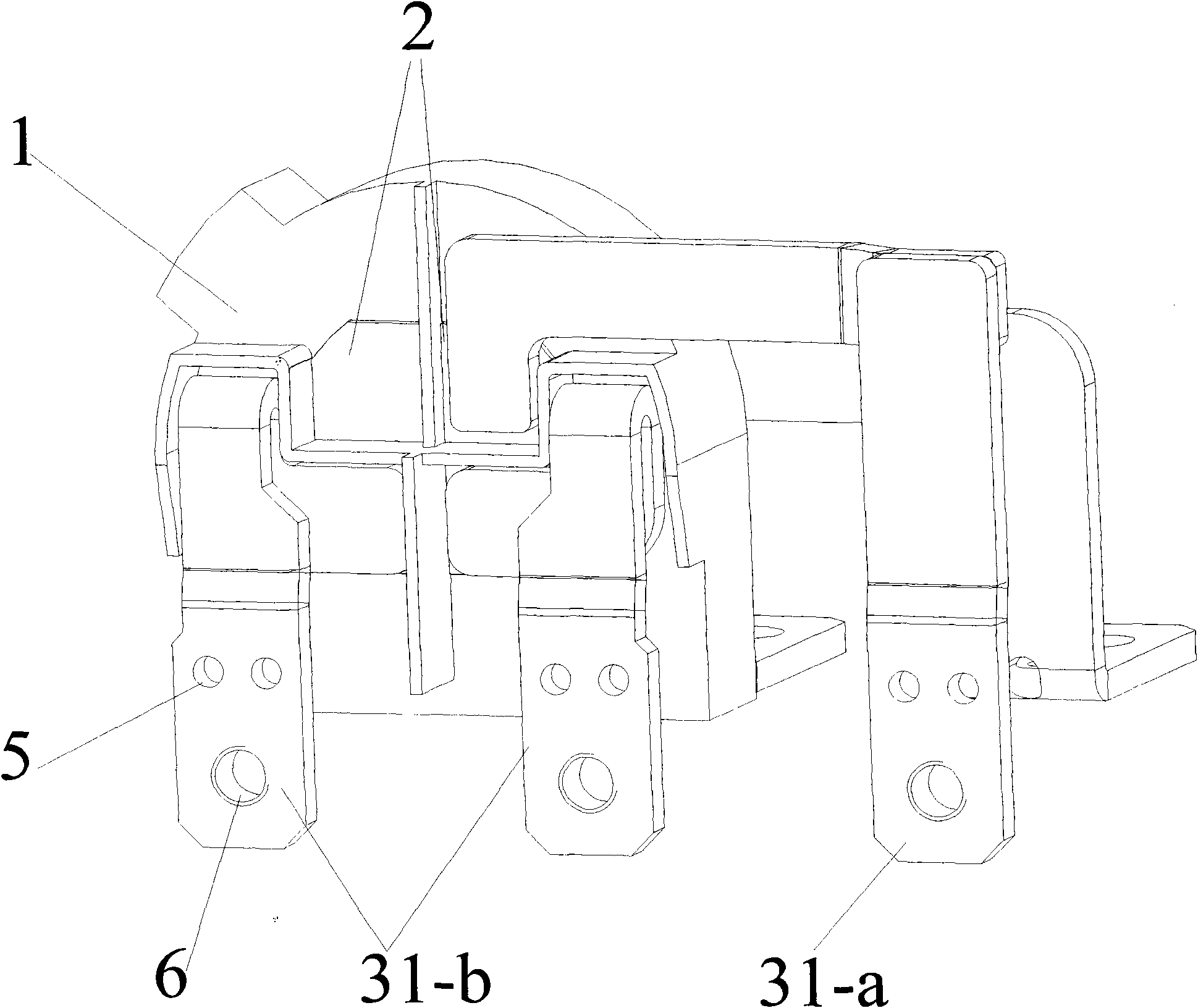

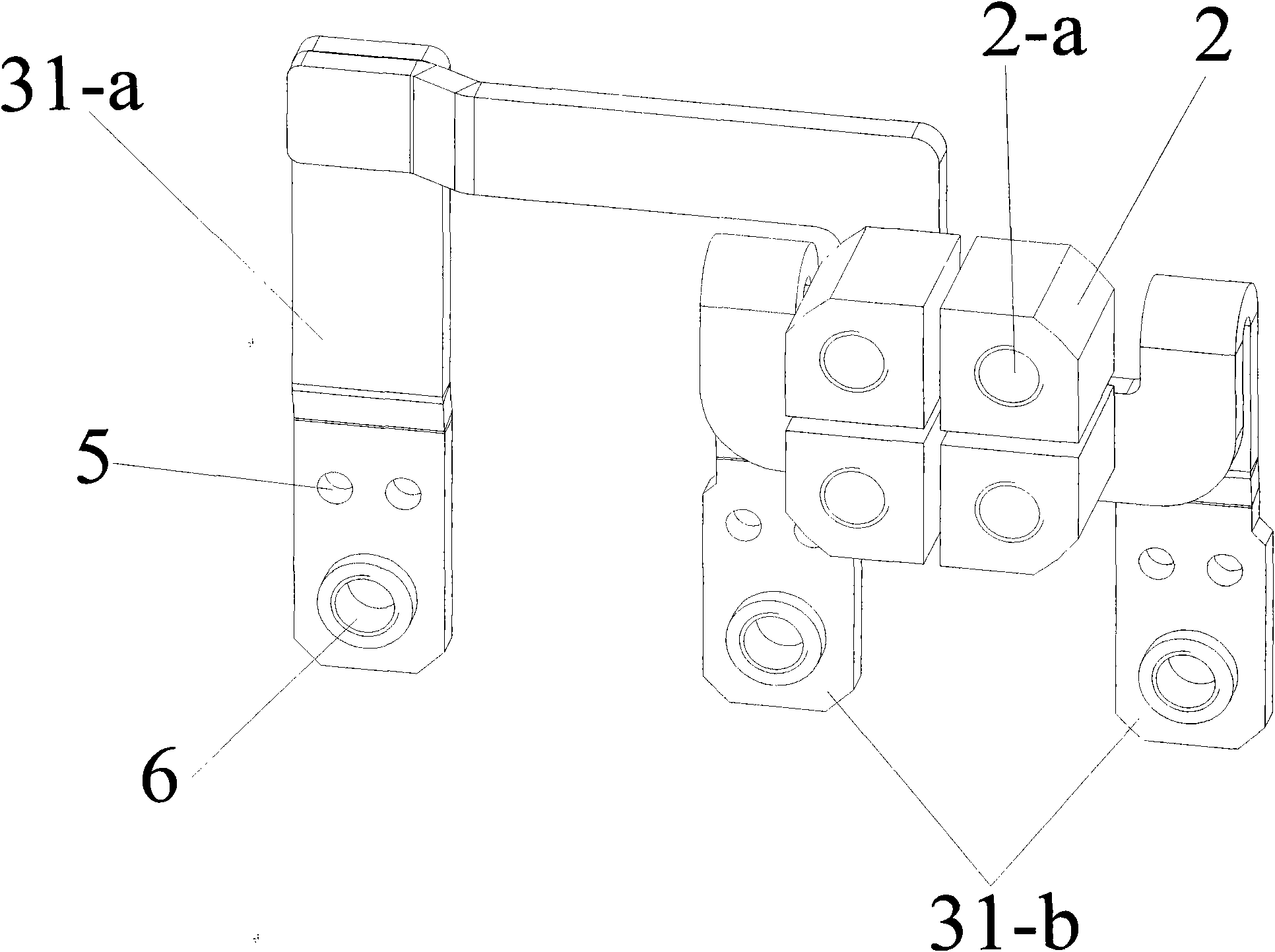

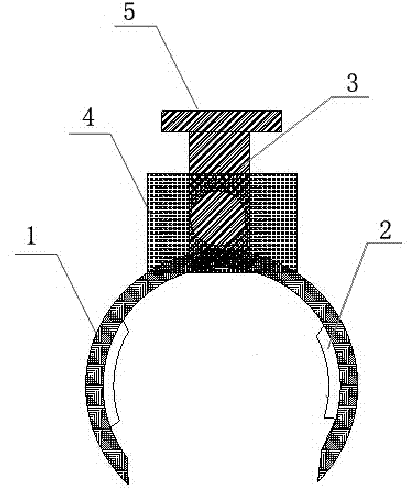

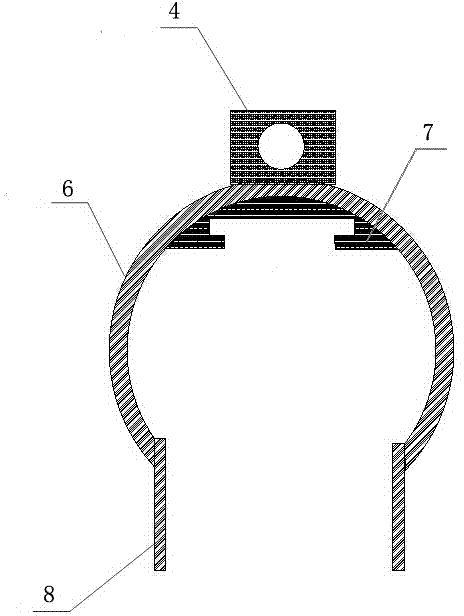

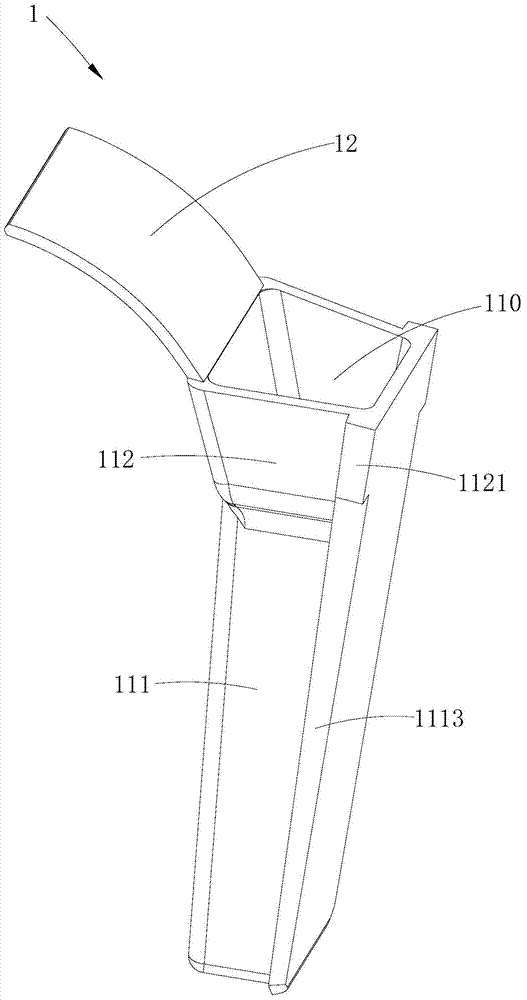

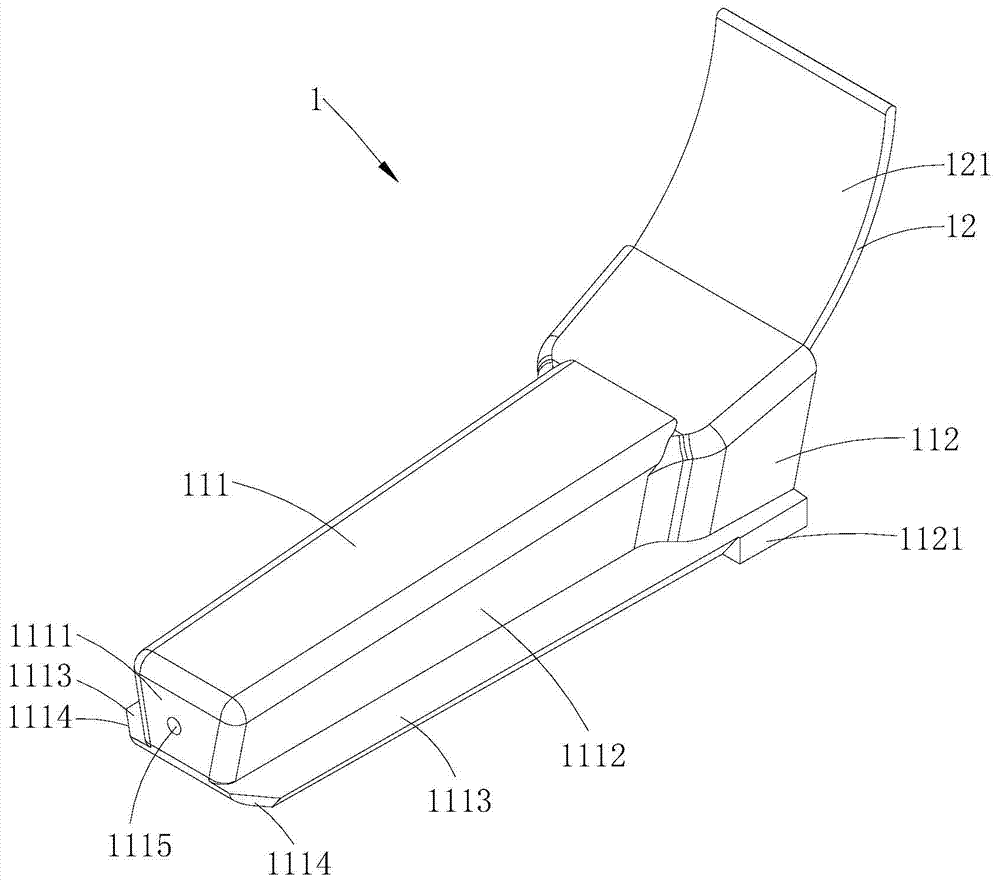

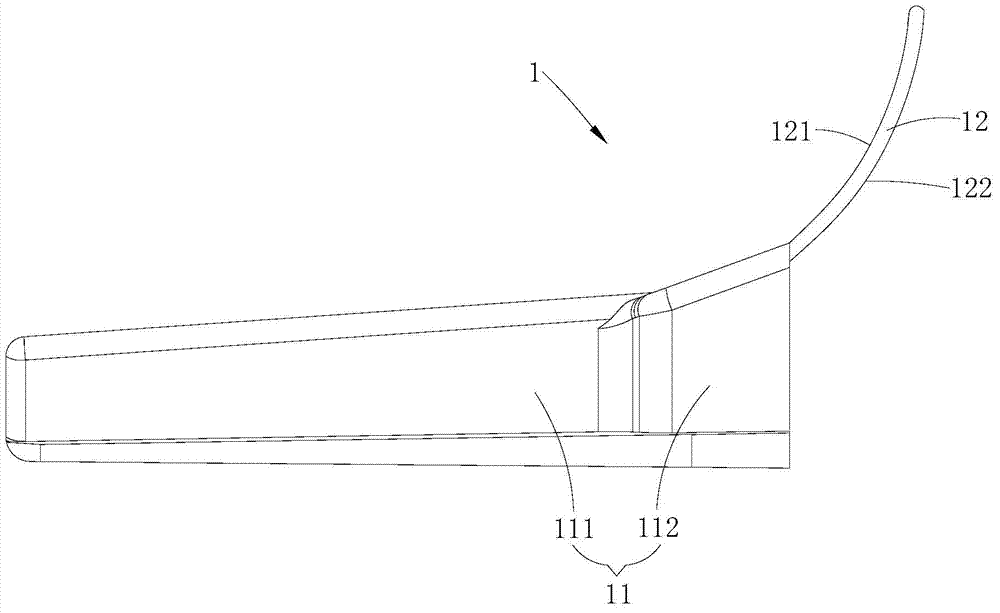

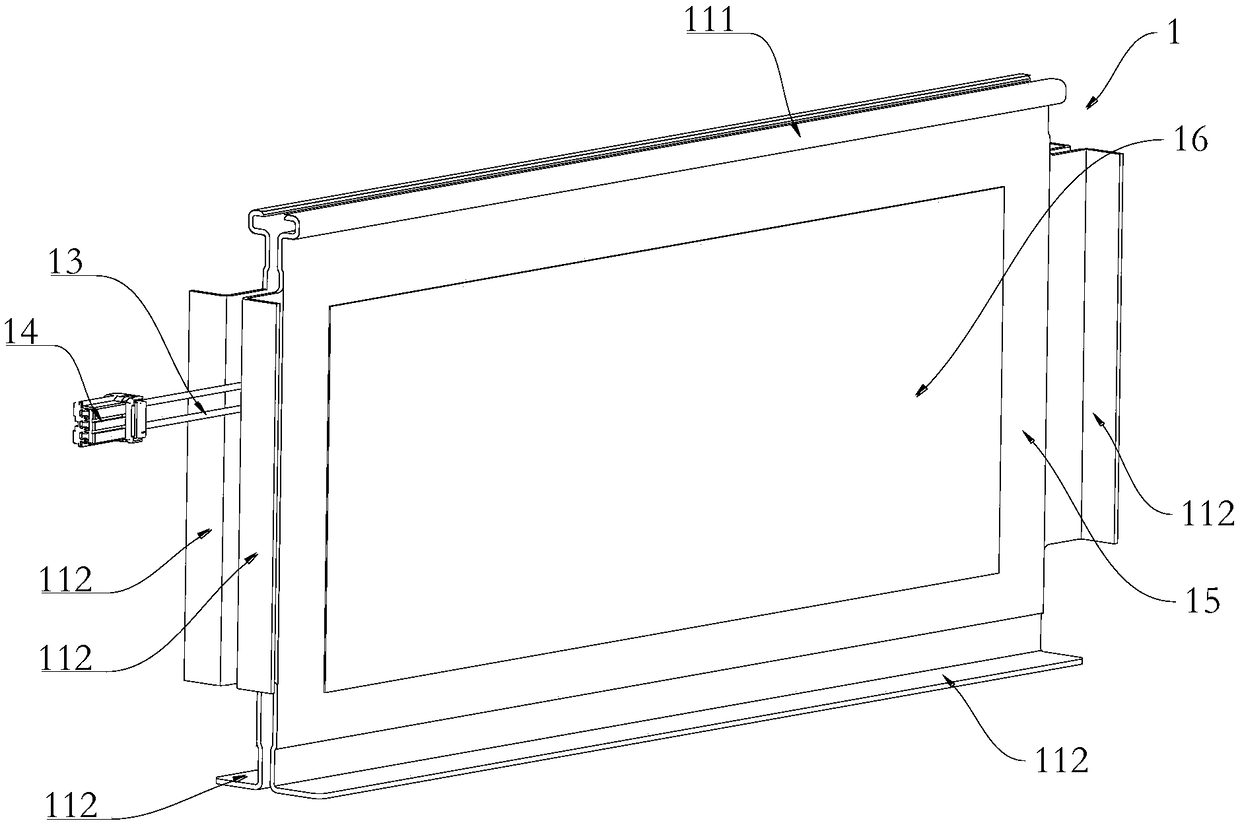

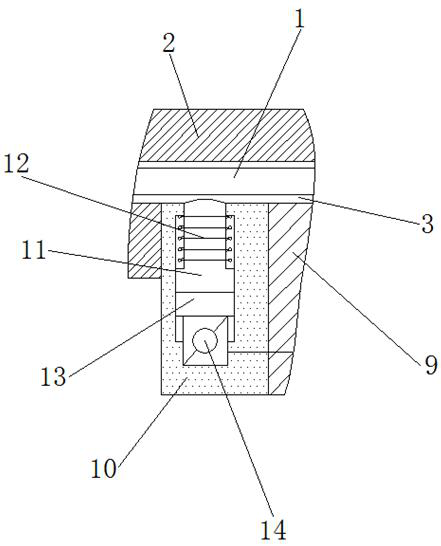

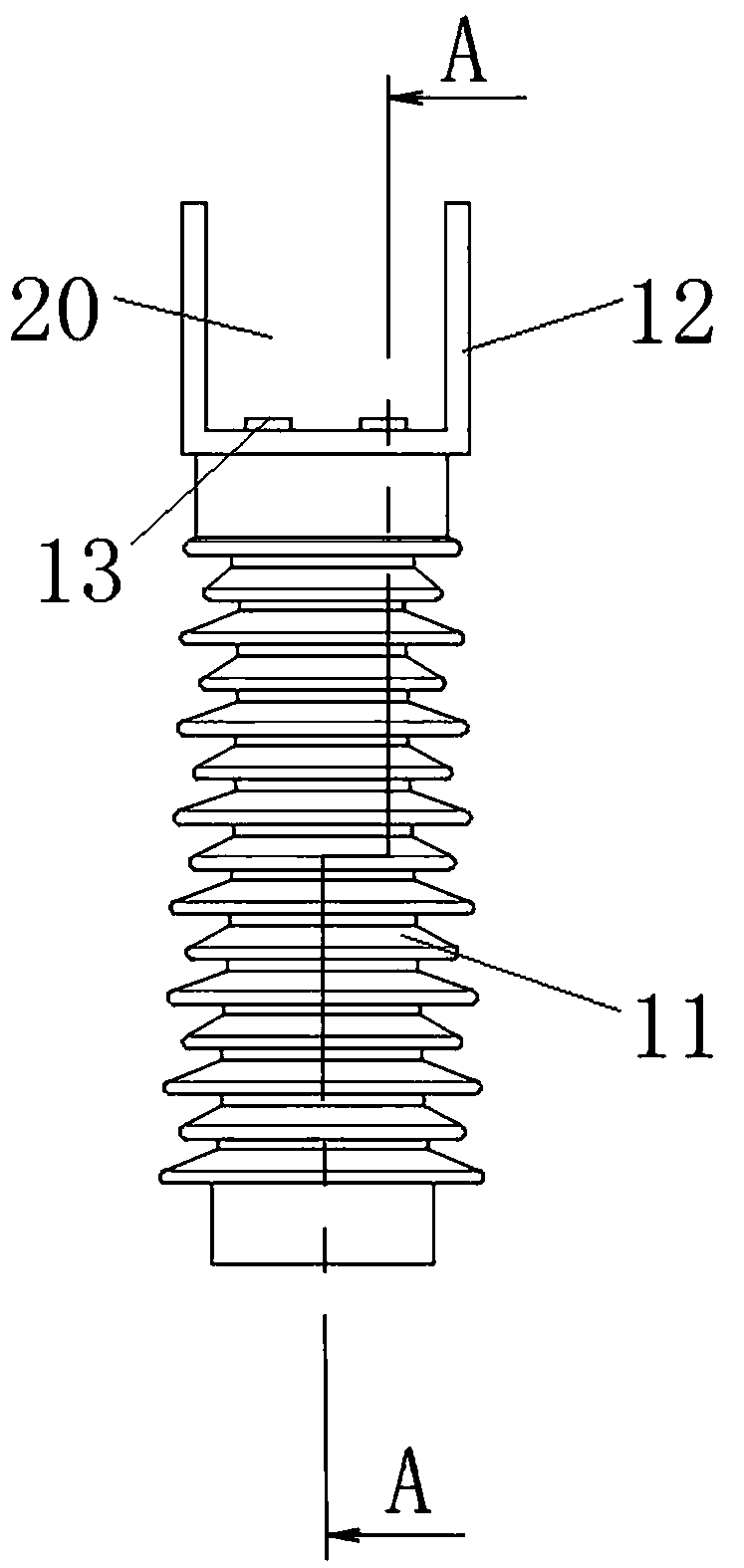

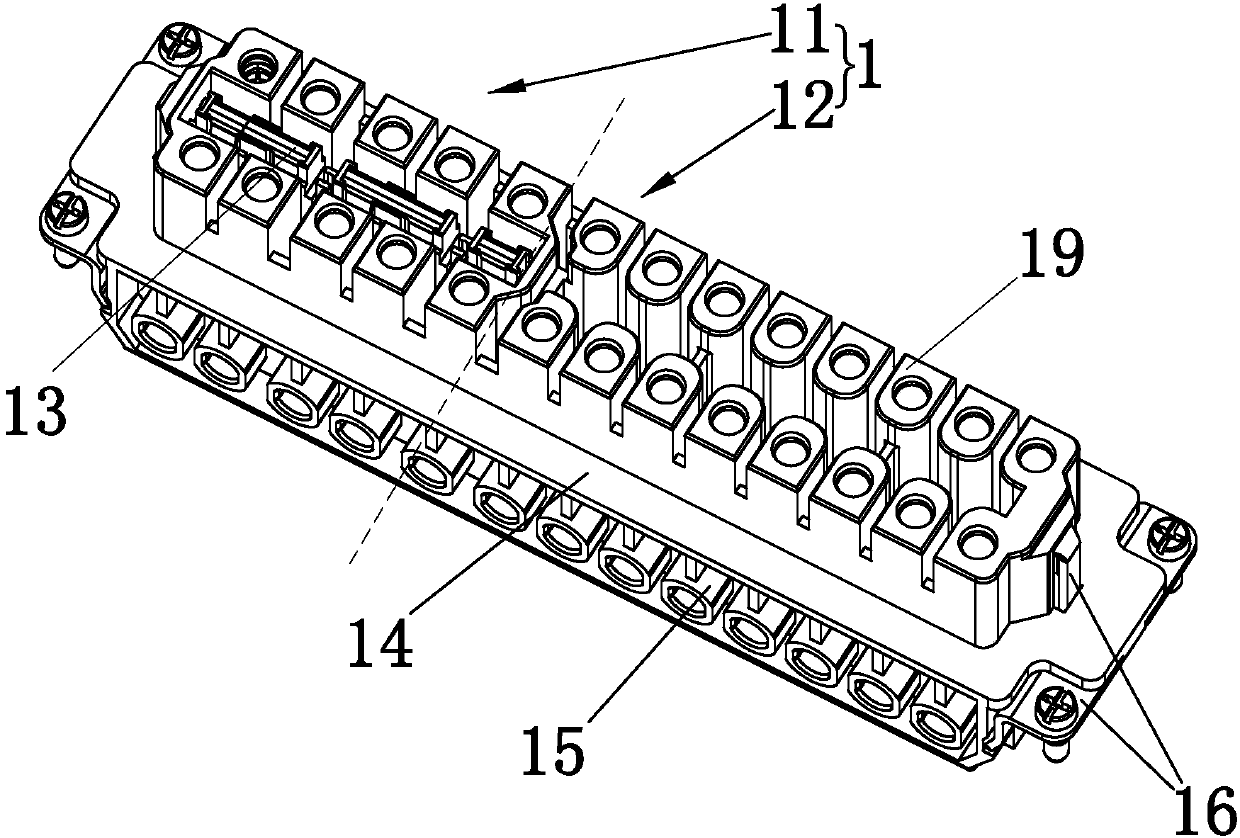

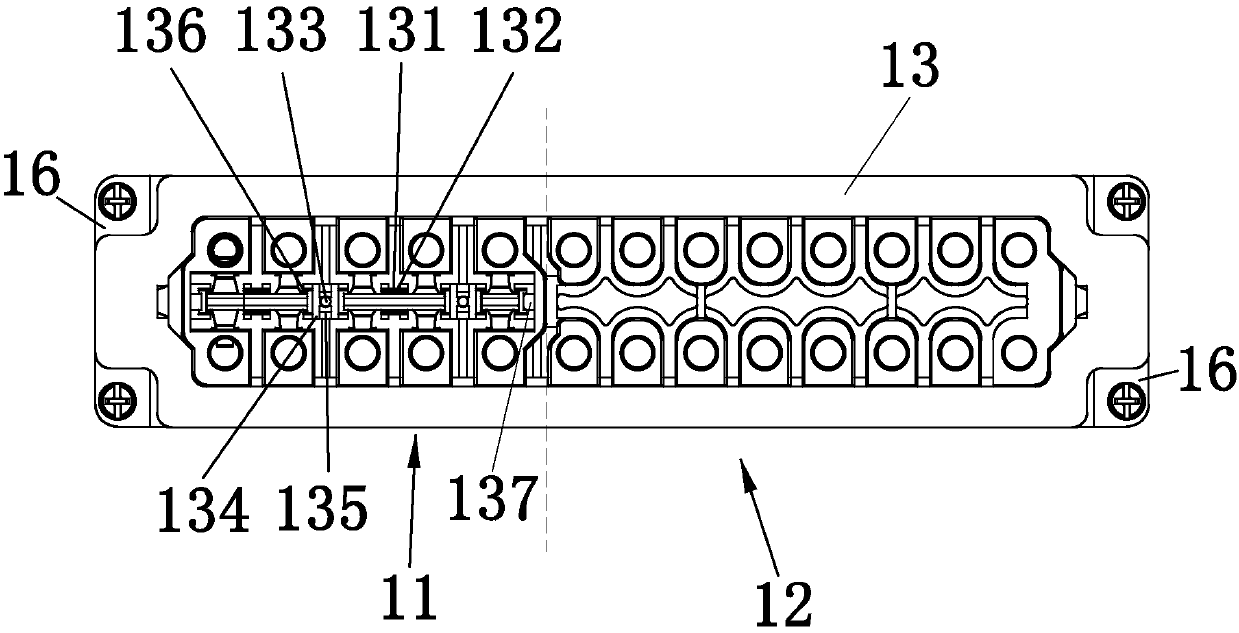

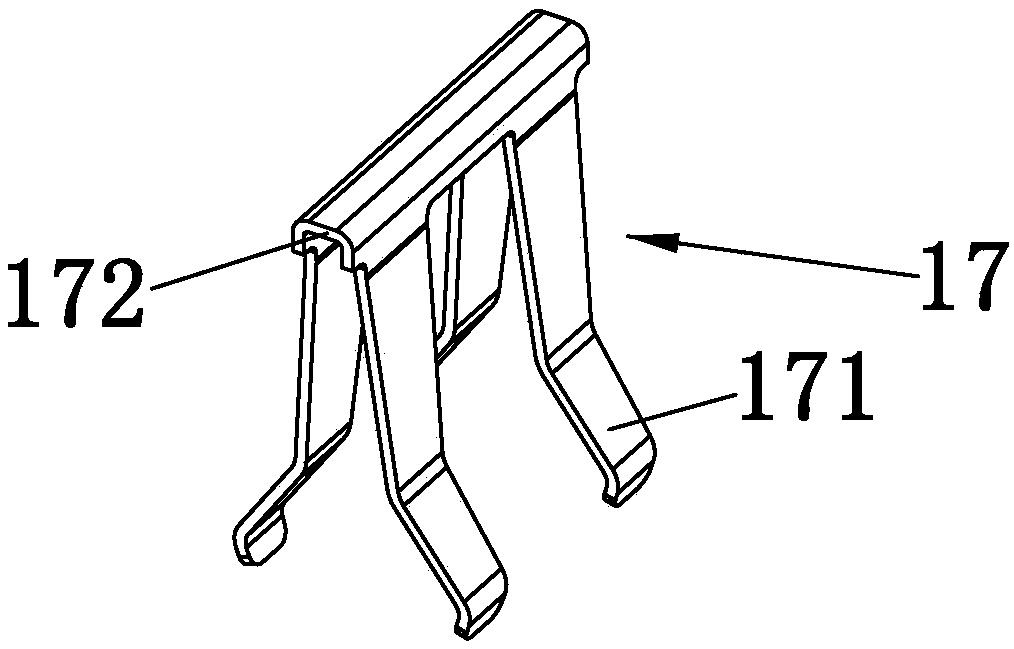

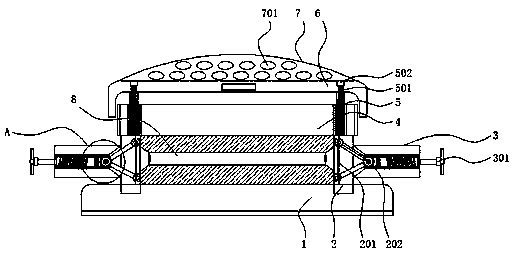

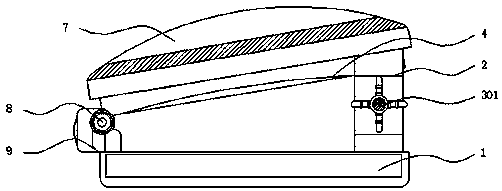

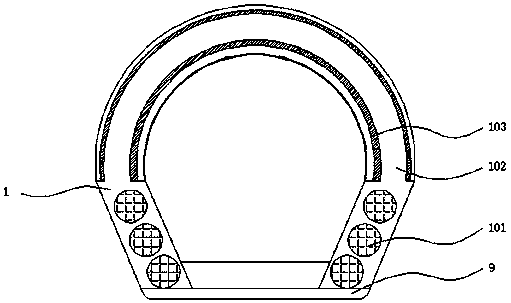

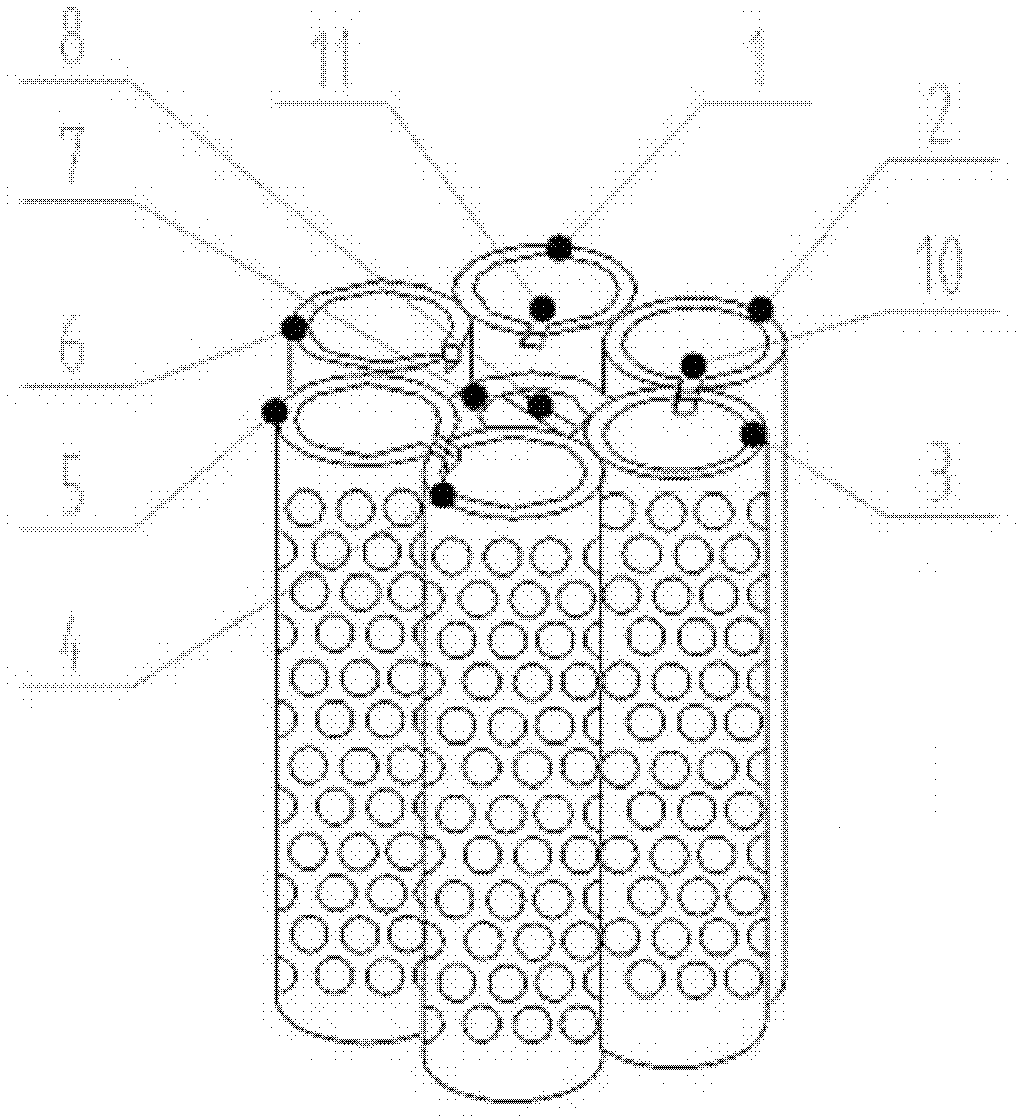

Zero sequence current mutual inductor

ActiveCN101958191APlay the role of insulation protectionSmall footprintTransformersTransformers/inductances coils/windings/connectionsInductorCopper

The invention relates to a zero sequence current mutual inductor. A separated region is positioned in the center of the zero sequence current mutual inductor body (1), so that the zero sequence current mutual inductor body (1) is divided into a front separated region structure (11) of the mutual inductor body and a back separated region structure (12) of the mutual inductor body; the front separated region structure (11) of the mutual inductor body and the back separated region structure (12) of the mutual inductor body have a cross raised structure respectively, and are both divided into four separated regions, and a conductive copper rod (2) and back conductive copper bars are integrated into a whole; the conductive copper rod (2) is arranged in the central separated region of the zero sequence current mutual inductor body (1); a threaded hole (2-a) is formed on the conductive copper rod (2); a screw (4) passes through the zero sequence current mutual inductor, so that front conductive copper bars are connected with the back conductive copper bars welded on the conductive copper rod (2); and the front conductive copper bars are positioned on the front separated region structure (11) of the mutual inductor body, and the back conductive copper bars are positioned on the back separated region structure (12) of the mutual inductor body.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

Modulus matching two-dimensional plane strain field test sensing element and manufacturing method thereof

InactiveCN105115413AStrain sensitiveGuaranteed insulation performanceElectrical/magnetic solid deformation measurementEngineeringField tests

A modulus matching two-dimensional plane strain field test sensing element and the manufacturing method thereof relate to sensing elements and manufacturing method thereof. The modulus matching two-dimensional plane strain field test sensing element comprises a first thin plate layer, a second sensing element display and lateral electrode layer, a third insulating thin layer, a fourth vertical electrode layer and a fifth insulation and protection film layer, wherein the first thin plate layer is a plastic or rubber thin plate, the second sensing element display and lateral electrode layer is printed on the first thin plate layer through a printing means, the third insulating thin layer is printed with resin or rubber, the fourth vertical electrode layer is also formed through printing, and the fifth insulation and protection film layer is printed with resin or rubber. The sensing element can be used for better testing a two-dimensional plane strain field, and reaches synchronous strain with an object to be tested, the strain obtained through test is more accurate, and the strain test range is satisfactory. The test precision is improved. Since printing technology is employed in the method, the cost is low and the effect is good for mass production.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

Heat insulation type wire insulation shield

ActiveCN104779003AReduce weightEasy to operateClimate change adaptationInsulated cablesInsulation layerDirect current

The invention discloses a heat insulation type wire insulation shield. The shield is of a double-layer shielding structure, the inner layer is a heat insulation layer, and the outer layer is an insulation layer; the inner layer and the outer layer are connected through a connecting block; the connecting block is a heat-resistant flame-retardant connecting block; installation chutes are formed in the two ends of the shield and connected with other shields in a matched mode; lifting holes are formed in the insulation layer and the heat insulation layer; the heat insulation layer is made of a heat insulation flame-retardant material; an anti-skidding pad is arranged on the inner side of the heat insulation layer; the connecting block is arranged on the outer side of the heat insulation layer and a sliding block is arranged at the upper end of the connecting block. The heat insulation type wire insulation shield can be used for achieving the wire insulation shielding function in the direct current grounding electrode circuit hot-line work process, the influences of the high temperature of wires on the insulation material and operation personnel are effectively eliminated, and the insulation protective effect is achieved.

Owner:国网河南省电力公司超高压公司 +2

Motor wiring welding joint protection part and wiring method of winding lead and power supply wire

ActiveCN104852499AImprove solid reliabilityImprove product qualityWindingsManufacturing dynamo-electric machinesEngineeringConductor Coil

The invention is applicable to the field of motors, and discloses a motor wiring welding joint protection part and a wiring method of a winding lead and a power supply wire. The motor wiring welding joint protection part comprises an insulating body, wherein an inner cavity into which a wiring welding joint of the winding lead and the power supply wire is stuffed and located is formed in the insulating body; the insulating body comprises an inserting part which can be clamped and inserted into a winding groove of an iron core, and a clamping part which is arranged at one end of the inserting part in a convex manner and is clamped outside the winding groove; the inserting part comprises a bottom plate far away from the clamping part, and a plurality of side plates which are arranged in an annular manner in the circumferential direction and is connected between the bottom plate and the clamping part; positioning convex plates which can be clamped and inserted between an insulating frame and the tooth boot of the iron core are arranged on two opposite edges which extend in opposite direction, of one side plate in the convex manner. Due to the novel motor wiring welding joint protection part, the wiring welding joint of the winding lead and the power supply wire can be protected, the wiring efficiency of the winding lead and the power supply wire can be improved, the protection reliability of the wiring welding joint is improved, and the production efficiency and the production quality of a motor can be improved.

Owner:WELLING WUHU MOTOR MFG

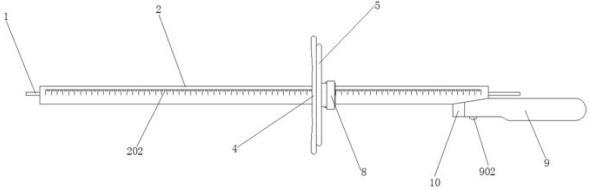

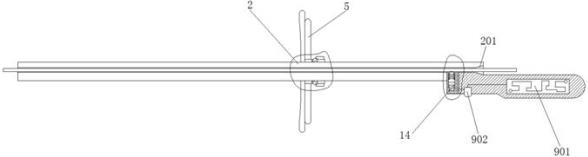

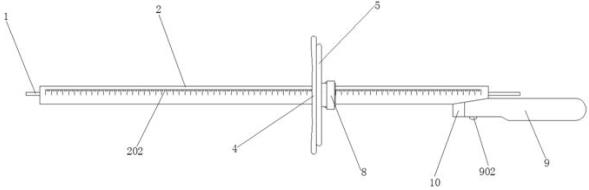

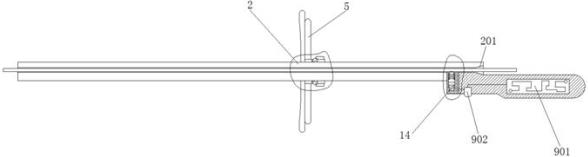

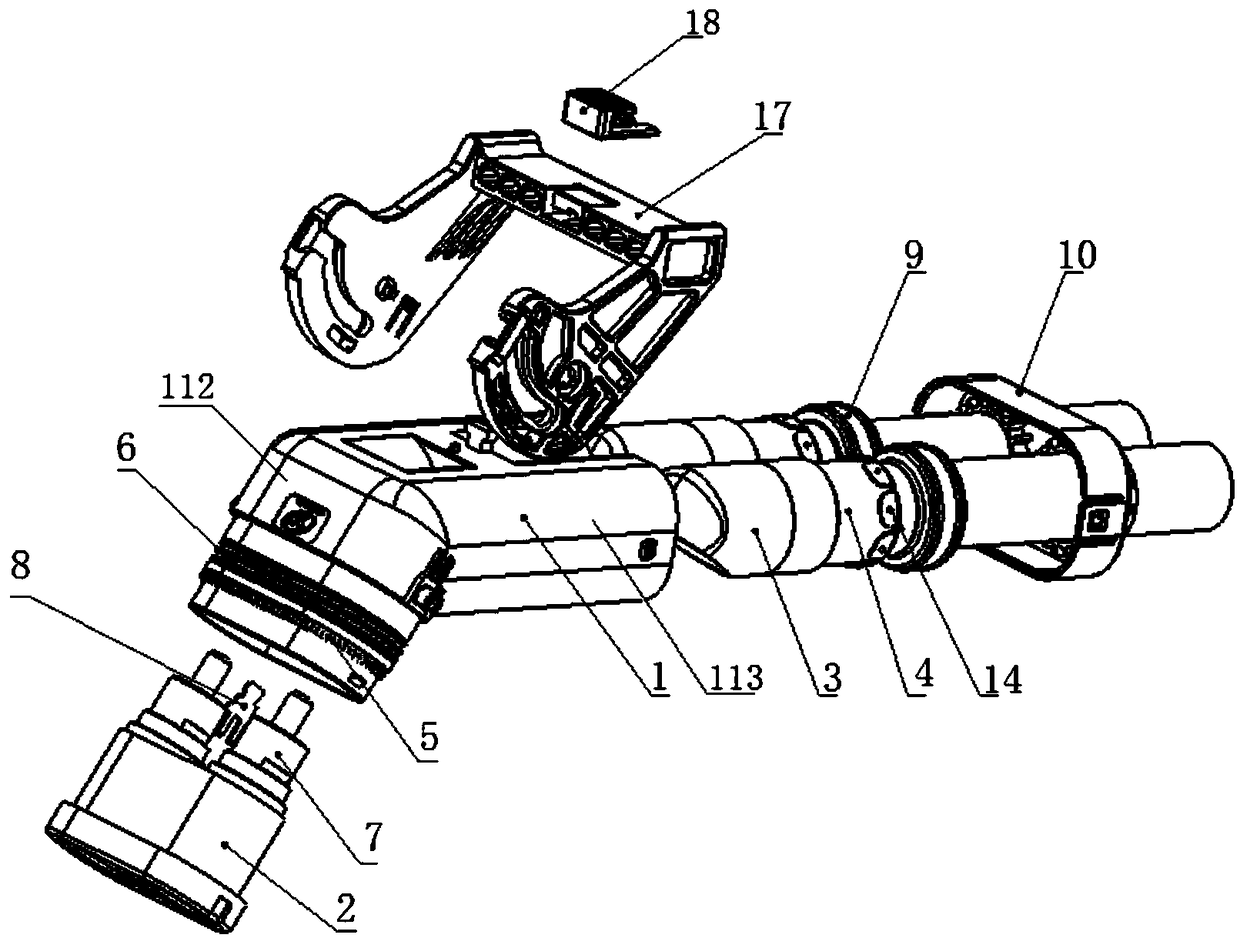

Adjustable microcatheter for cerebrovascular intervention and use method thereof

InactiveCN112169137AAchieve clampingGuaranteed positioningGuide wiresEngineeringIntensive care medicine

The invention discloses an adjustable microcatheter for cerebrovascular intervention and a use method thereof. The adjustable microcatheter comprises a guide wire, and further comprises a catheter body, an avoidance hole, a patch, a soft cushion, a clamping sleeve, clamping plates, a threaded sleeve, a handle, an insulating sleeve, a push plate, a spring, a conductive block and an electromagnet. The adjustable microcatheter for cerebrovascular intervention is easy to operate and powerful in function. Firstly, the catheter can be positioned and fixed through the catheter fixing type design, andthe stability and safety in a subsequent operation process are ensured; and secondly, the guide wire in the catheter can be positioned through the cooperation effect of a clamping type guide wire mechanism, the accuracy of treatment operation is improved, the operation burden of medical staff is relieved, and the purpose of satisfactory clinical application and popularization is finally achieved.

Owner:万海伟

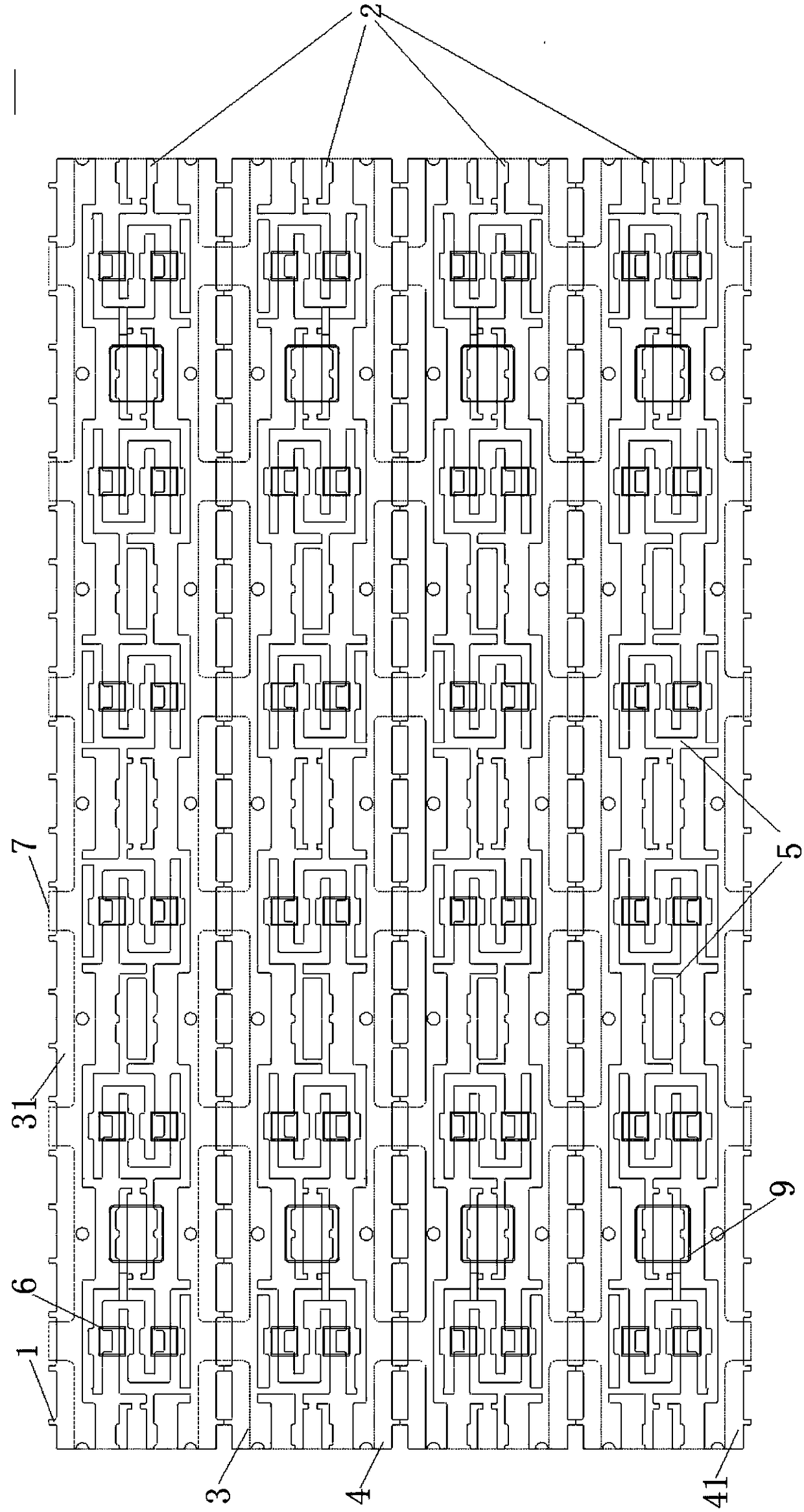

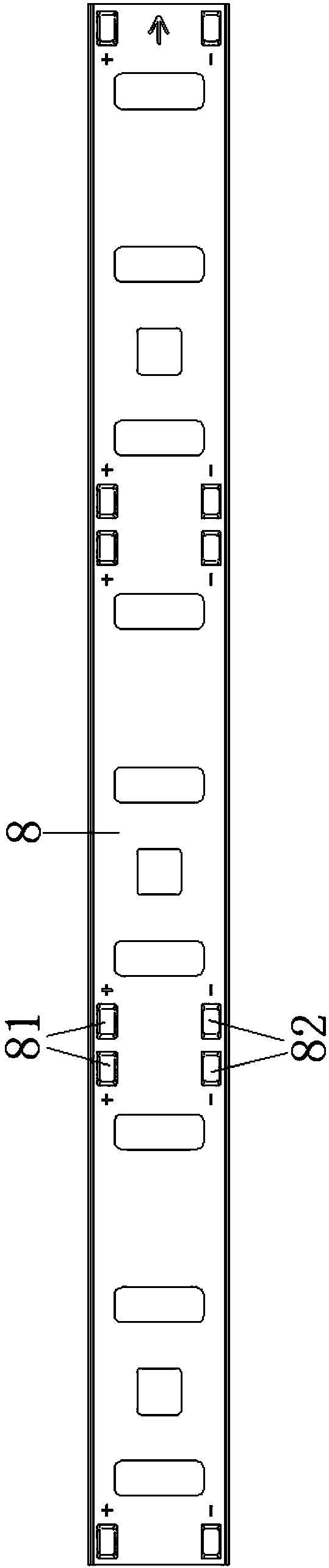

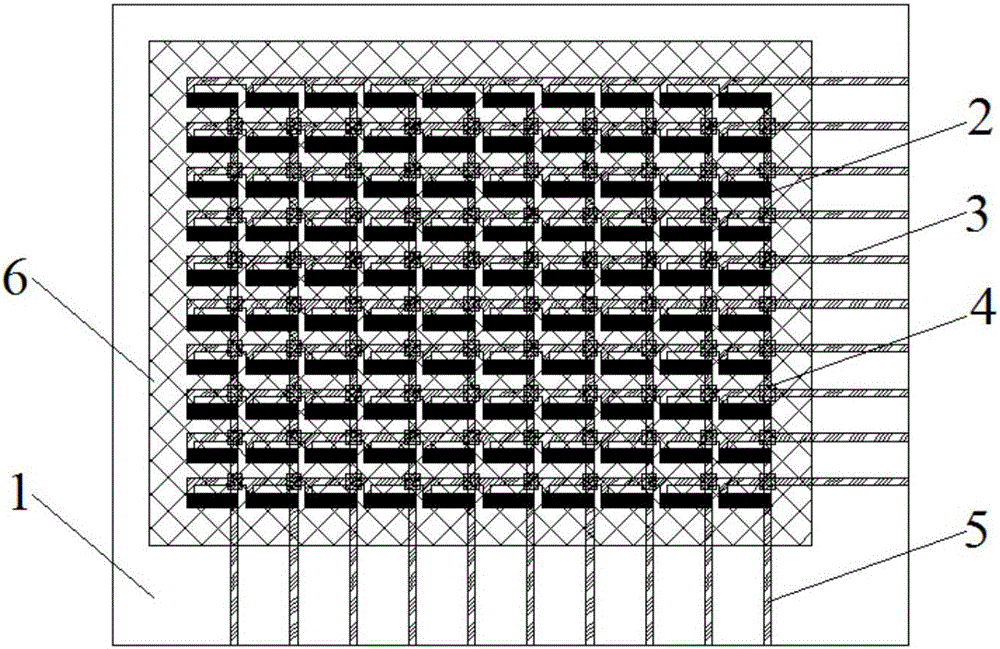

Double-row and multiple-row LED lamp baseband

PendingCN108278515AAccurate line layoutReduce production processPlanar light sourcesElectric circuit arrangementsDouble rowConstant power circuit

The invention relates to a double-row and multiple-row LED lamp baseband. The double-rows and multiple-row LED lamp baseband comprises a circuit baseband and lamp beads; the circuit baseband is formedby integrally punching a bendable conductive metal band; a plurality of circuit strips are formed on the conductive metal band; each circuit strip is provided with a first power circuit, a second power circuit and a plurality of element circuits, wherein the element circuits are connected in parallel; each element circuit is provided with a plurality of lamp bead installation regions which are arranged in an MXN matrix form, wherein in the lamp bead installation regions, M lamp beads are firstly connected in parallel and subsequently N lamp bead groups consisting of the M lamp beads are connected in series; the lamp beads are installed at the lamp bead installation regions in an adhering manner; the element circuits, the overall outer surface of the lamp beads, and a part of the outer surfaces of the first and second power circuits are each coated with a transparent insulating film; a region, which is not coated with the transparent insulating film, of each first power circuit is usedas an anode connecting region; and a region, which is not coated with the transparent insulating film, of each second power circuit is used as a cathode connecting region. The double-row and multiple-row LED lamp baseband provided by the invention has the advantages of needing no printing circuit and being simple to manufacture, low in pollution and low in cost.

Owner:杭州小太阳农业科技有限公司

Method for live cleaning of contaminated insulator with high-temperature water vapor doped with alkanolamide

InactiveCN102671879AAvoid pollutionPlay the role of insulation protectionCleaning using liquidsWater savingWater vapor

The invention relates to a method for live cleaning of a contaminated insulator with high-temperature water vapor doped with alkanolamide. The method comprises the following steps of: firstly adding the alkanolamide accounting for 10% of total volume into water for cleaning to obtain mixed liquid, then placing the mixed liquid in an electric heating device, and starting a power supply of the electric heating device for heating the mixed liquid, wherein the heating temperature does not exceed 150 DEG C; and then sending the obtained high-temperature water vapor doped with the alkanolamide from a vapor compressor to a spray gun via a gas pipe, directly spraying to the contaminated insulator at the speed above 100m / s under the action of the vapor compressor, and cleaning three to four times from bottom to top so as to realize the live cleaning of the contaminated insulator. According to the method disclosed by the invention, the live cleaning problem of the contaminated insulator with high equivalent salt deposit density, high non-soluble deposit density and heavy oil dirt can be effectively solved, the safety and reliability in operation of electric power equipment can be ensured, and the method has the advantages of good cleaning effect, high speed, water saving, labor saving and low cost.

Owner:XI AN JIAOTONG UNIV +1

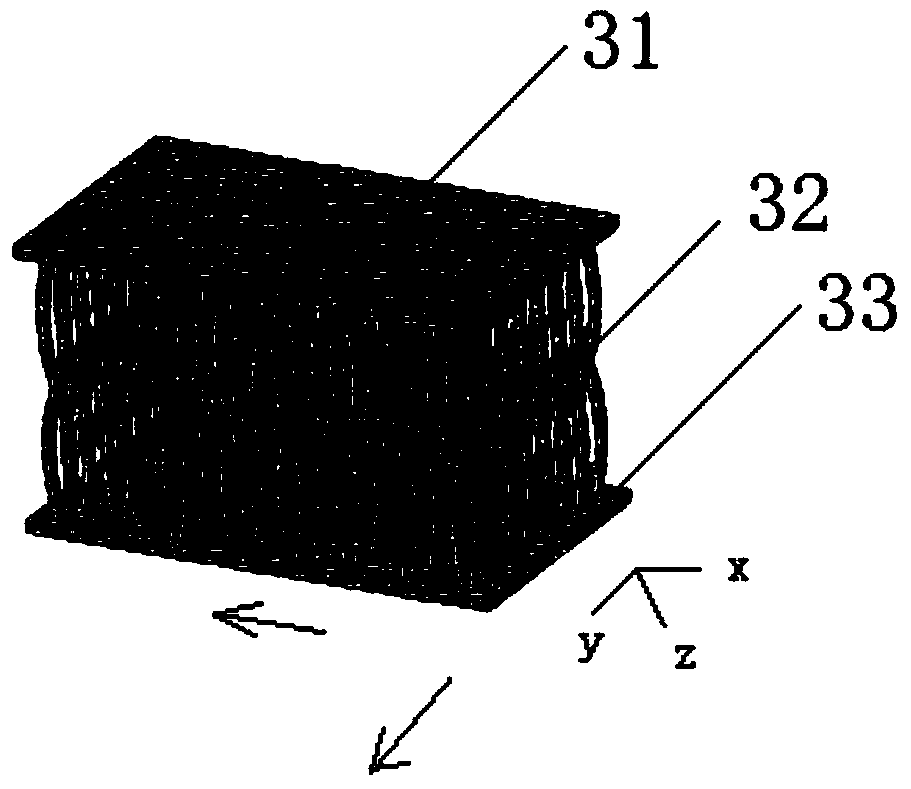

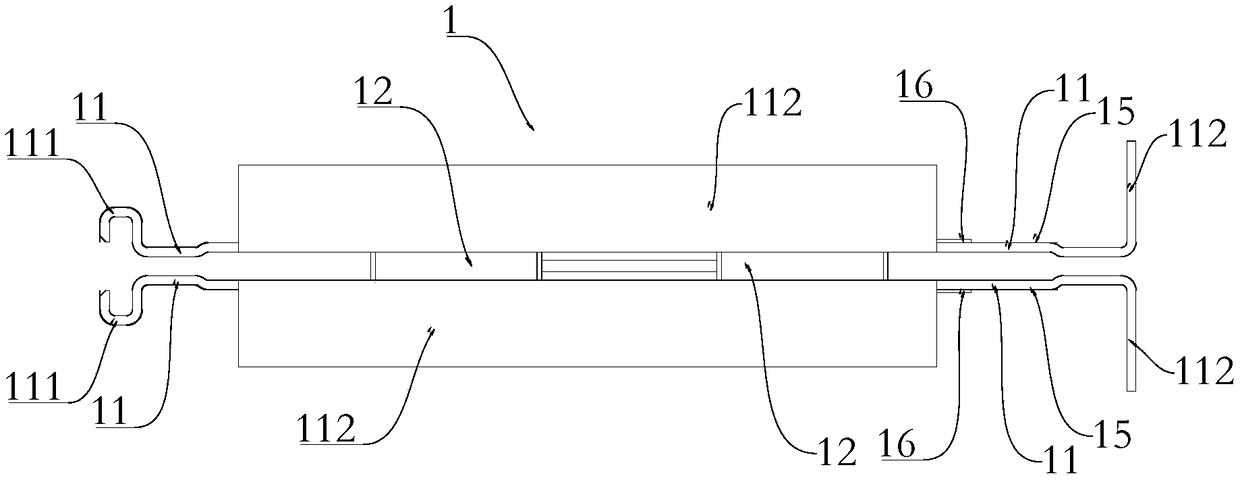

A battery module heating device and a battery module

PendingCN109256510AMaximize absorptionIncrease profitSecondary cellsCell component detailsEngineeringCell contact

The invention relates to a battery module heating device and a battery module. The heating device comprises two connecting plates and heating elements. The two connecting plates are arranged oppositeto each other. A mounting gap is reserved between the two connecting plates. The heating elements are arranged in the mounting gap and are fixedly connected with the two connecting plates respectively. The heating device of the invention, A heating element is arranged between the two connecting plates. When the heating device is used in the battery module, the two connecting plates can be heated by the heating element respectively, and the cell contacting with the connecting plate can be heated, so that the heat energy generated by the heating element can be absorbed by the cell maximally, andthe utilization rate of energy can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

Adjustable microcatheter for cerebrovascular intervention and use method thereof

InactiveCN112169135AAchieve clampingGuaranteed positioningGuide wiresIntensive care medicineGuide wires

The invention discloses an adjustable microcatheter for cerebrovascular intervention and a use method thereof. The adjustable microcatheter comprises a guide wire, and further comprises a catheter body, an avoidance hole, a patch, a soft cushion, a clamping sleeve, clamping plates, a threaded sleeve, a handle, an insulating sleeve, a push plate, a spring, a conductive block and an electromagnet. The adjustable microcatheter for cerebrovascular intervention is easy to operate and powerful in function. Firstly, the catheter can be positioned and fixed through the catheter fixing type design, andthe stability and safety in a subsequent operation process are ensured; and secondly, the guide wire in the catheter can be positioned through the cooperation effect of a clamping type guide wire mechanism, the accuracy of treatment operation is improved, the operation burden of medical staff is relieved, and the purpose of satisfactory clinical application and popularization is finally achieved.

Owner:万海伟

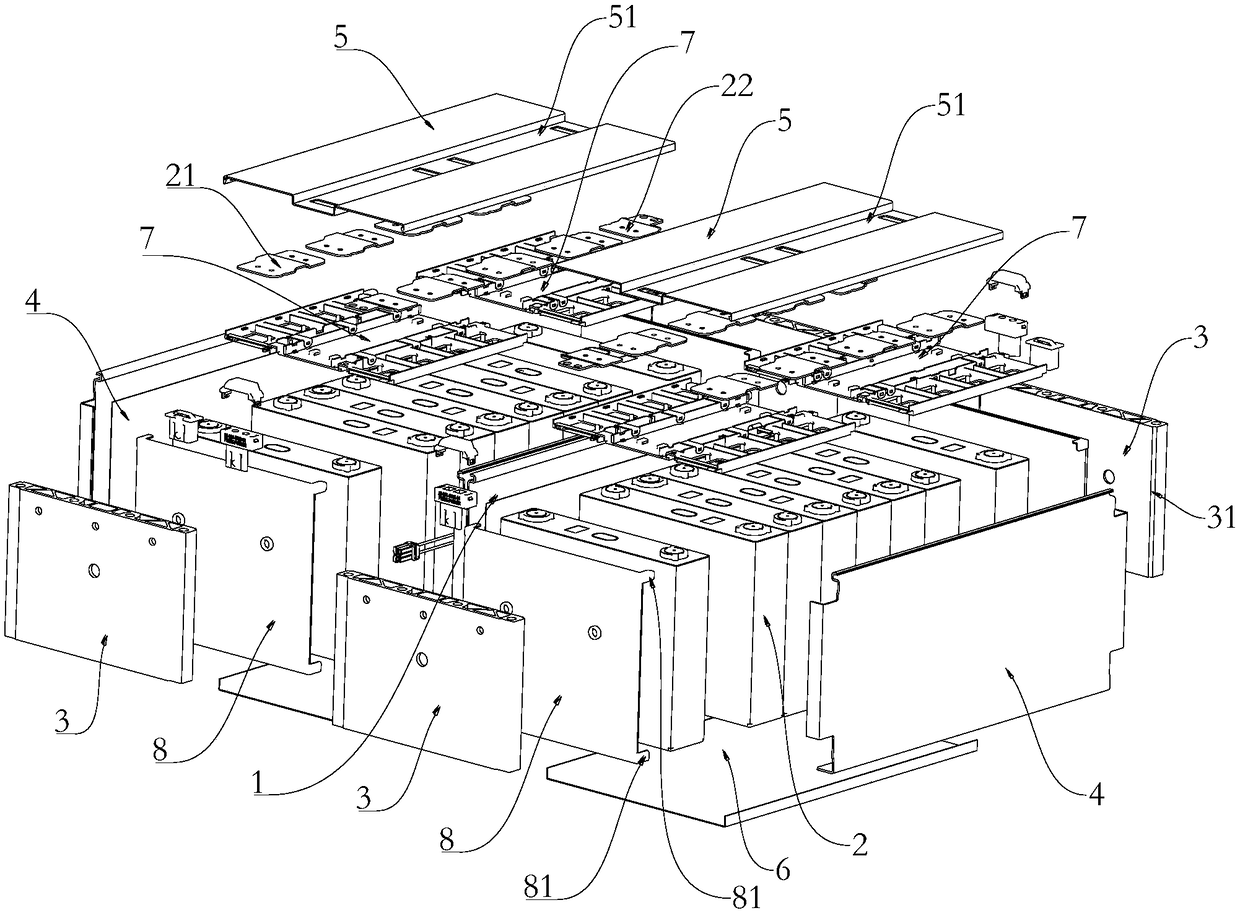

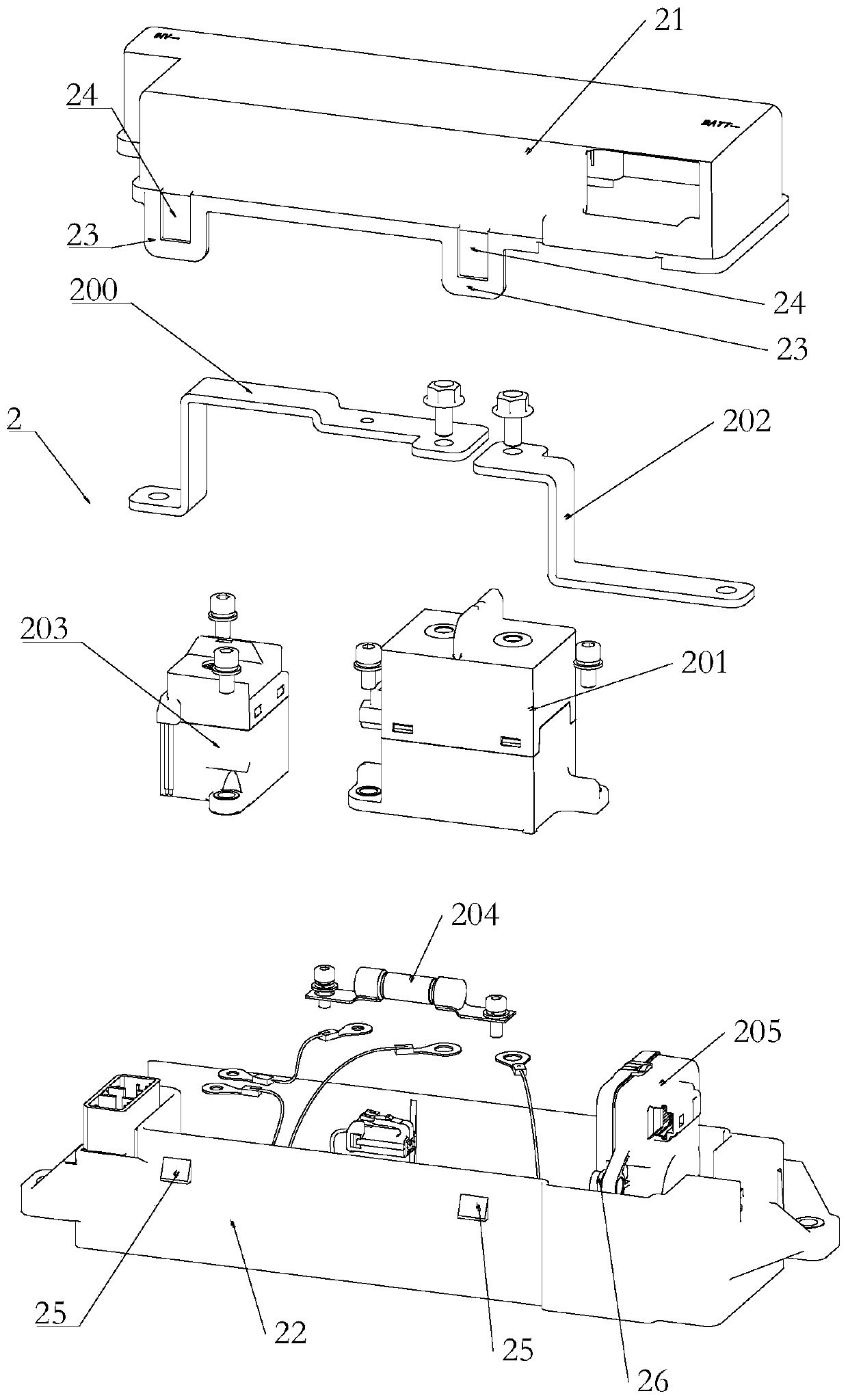

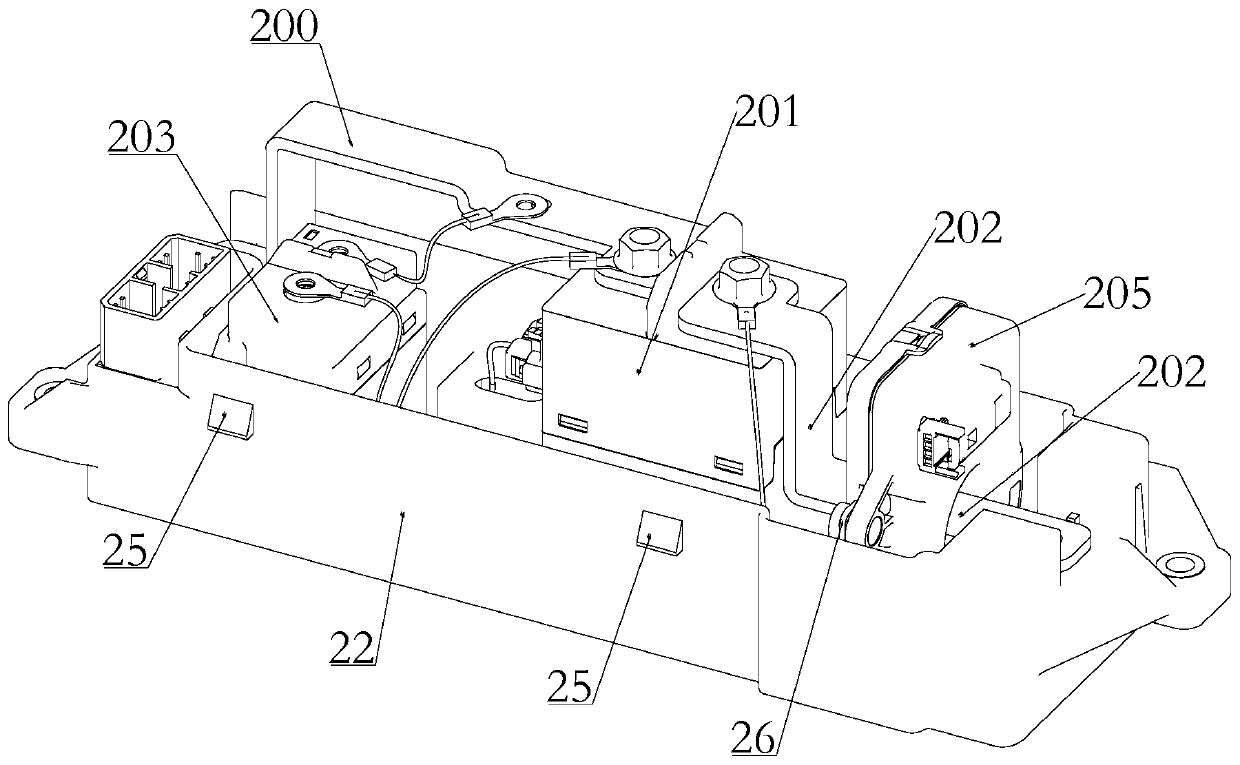

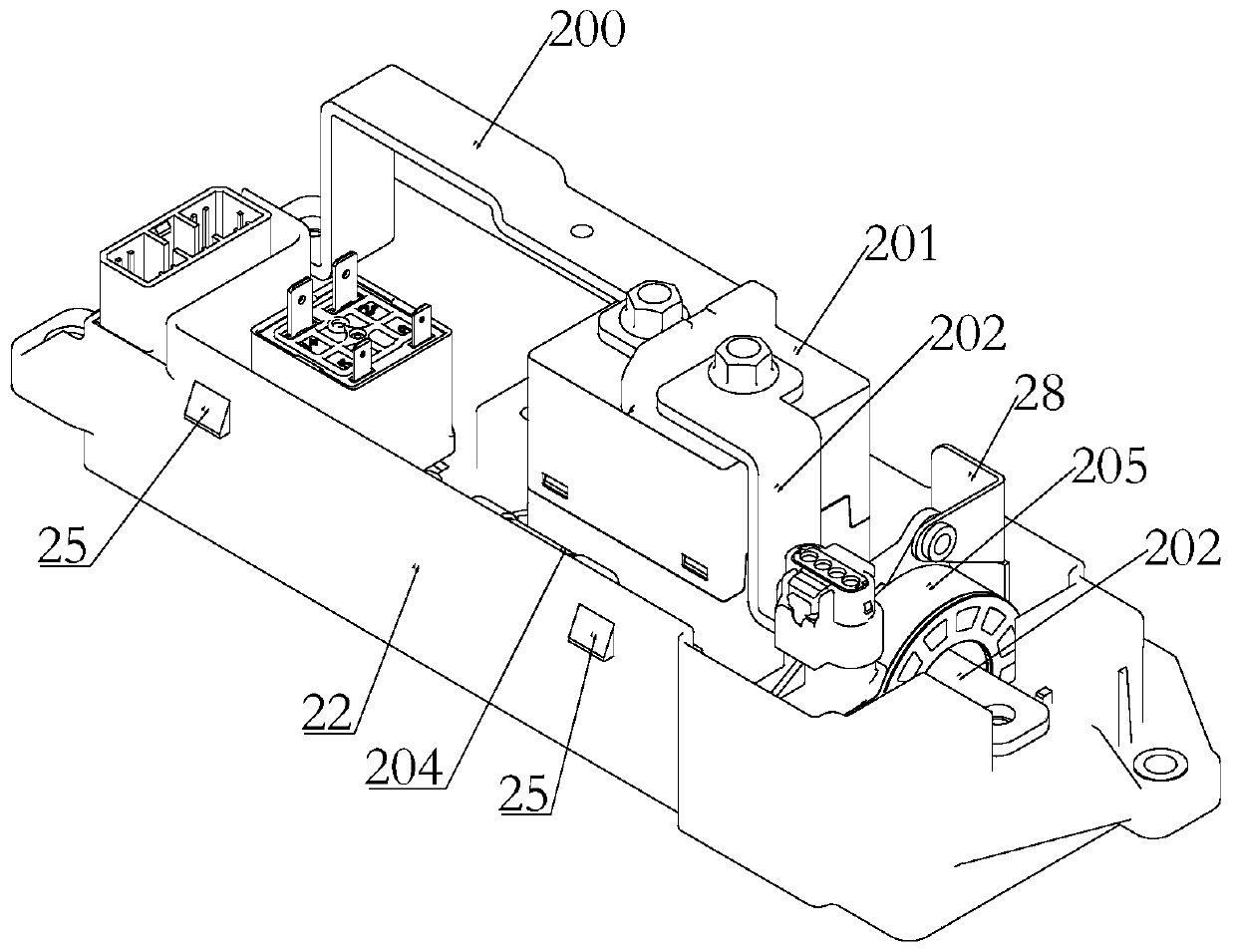

Universal economic compatibility BDU and battery pack

PendingCN110277525AReduce connectionsReduce weightCells structural combinationCell component detailsEngineeringBattery pack

The invention relates to a universal economic compatibility BDU and a battery pack. The BDU comprises a positive electrode BDU and a negative electrode BDU which are designed in a split manner. The positive electrode BDU comprises a positive electrode upper shell and a positive electrode lower shell, wherein the positive electrode upper shell is detachably connected with the positive electrode lower shell through a buckle. The negative electrode BDU comprises a negative electrode upper shell and a negative electrode lower shell, wherein the negative electrode upper shell is detachably connected with the negative electrode lower shell through a buckle. According to the BDU, the positive electrode and the negative electrode are integrated in different shells in a split mode, and the upper shell and the lower shell of the positive electrode BDU and the lower shell of the negative electrode BDU are respectively of a buckle design, thereby reducing the bolt connection, and effectively reducing the weight and cost of a system effectively. Moreover, due to the fact that an installation space in the battery pack is limited, the positive electrode BDU and the negative electrode BDU are designed in the split mode, so the limited space in the battery pack can be effectively utilized, the structure is compact, and the space is saved.

Owner:江苏和中普方新能源科技有限公司

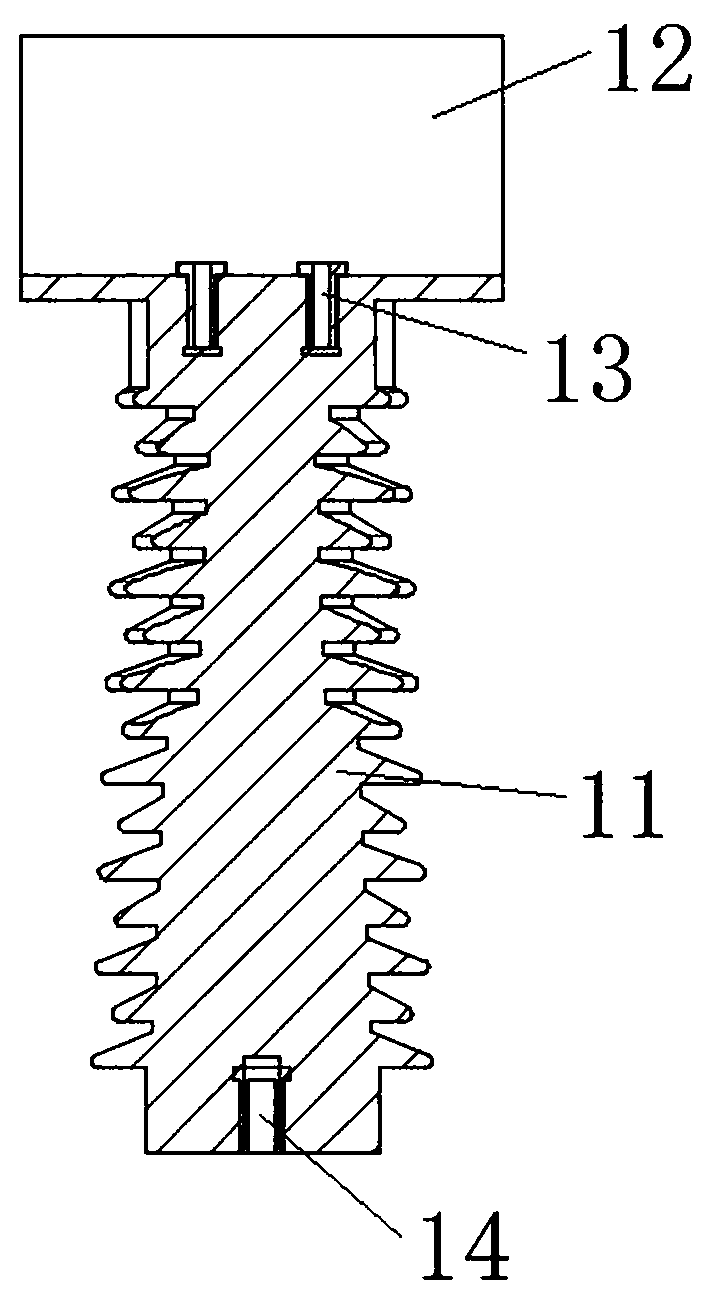

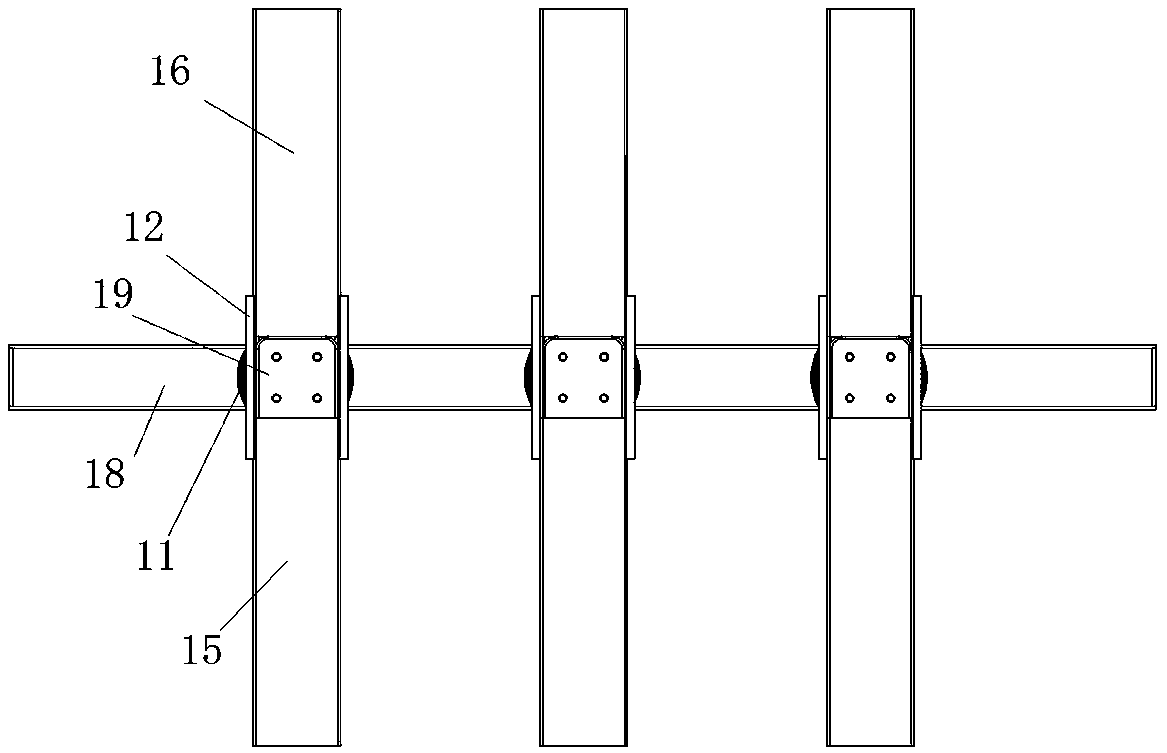

Bus-bar support insulator and switch cabinet

InactiveCN110729634APlay the role of insulation protectionPlay a supporting roleBus-bar/wiring layoutsButt joining bus-barsLap jointScrew thread

The invention relates to a bus-bar supporting insulator and a switch cabinet. The bus-bar supporting insulator comprises an insulating column and an insert; one end of the insulating column is used fixedly assembled on a switch cabinet body; two insulating protective wings are integrally formed at the other end of the insulating column; the two insulating protective wings and the insulating columndefine an installing groove for installing a bus-bar lap joint structure; the two insulating protective wings are used for realizing insulating protection for the bus-bar lap joint structure; the insert is embedded in the groove bottom of the installing groove; the insert is a threaded sleeve with internal threads and is matched with a threaded fastener to fixedly assemble the bus-bar lap joint structure in the installing groove, or the insert is a screw rod with external threads and is matched with a nut to fixedly assemble the bus-bar lap joint structure in the installing groove; the two insulating protective wings can realize insulation protection role for the bus-bar lap joint structure in the installation groove, an insulation distance between two phases is guaranteed; and the insulation column support the bus-bar lap joint structure, meanwhile, the threaded fastener or the nut is not exposed, and the discharge phenomenon of the threaded fastener or the nut is avoided.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

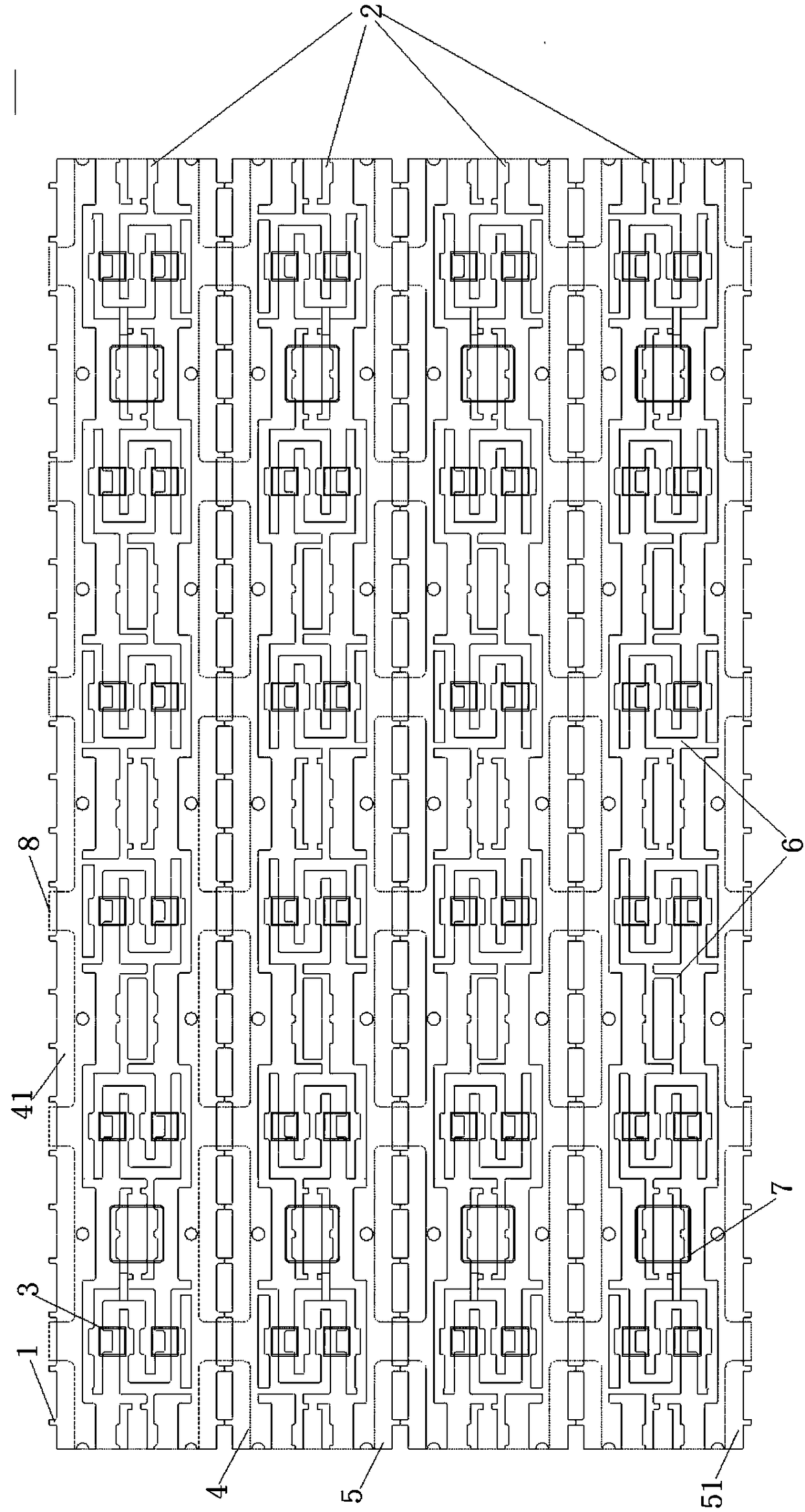

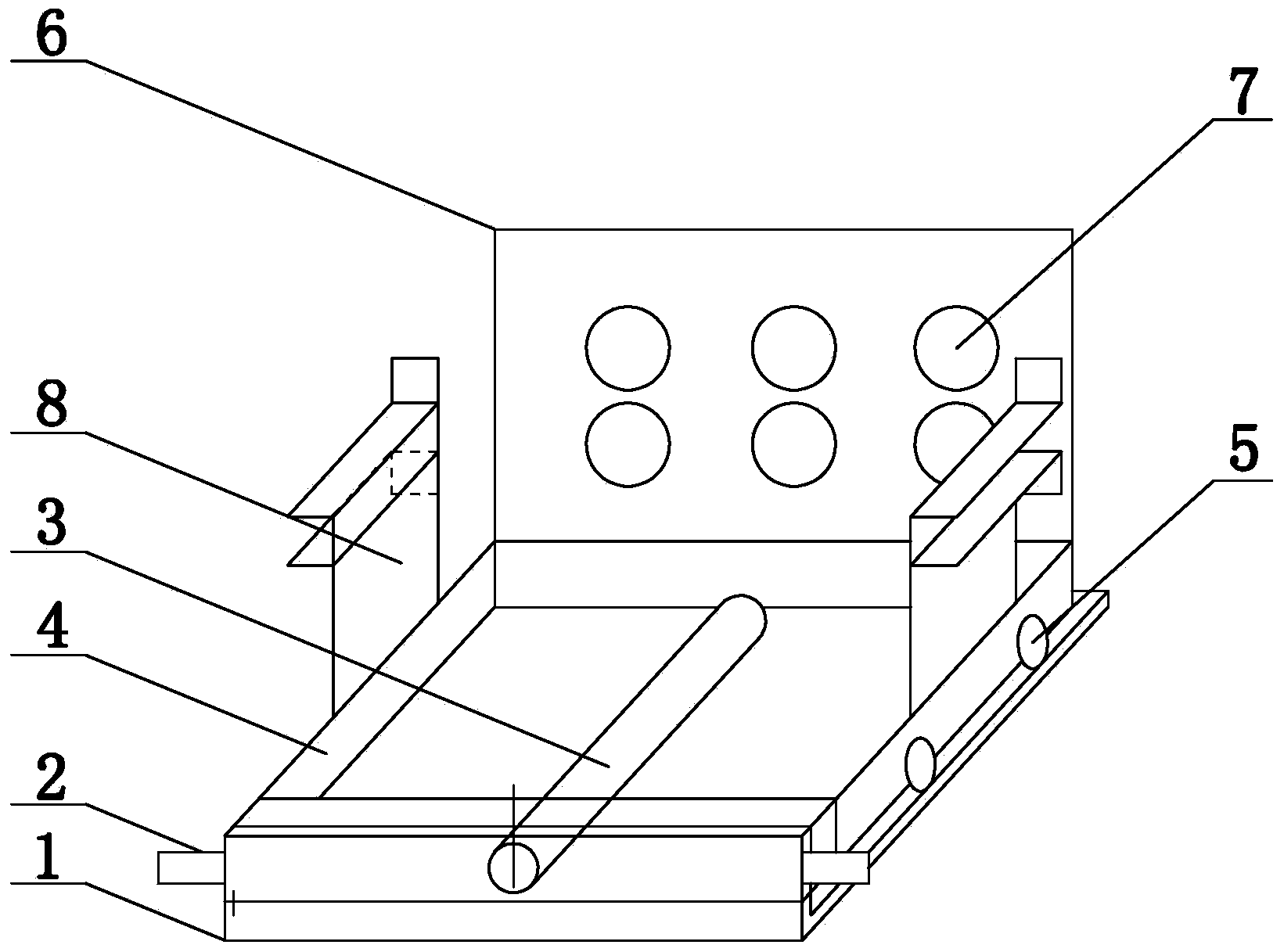

10KV switchgear nuclear phase vehicle

InactiveCN104348102AEnsure safetyPlay the role of insulation protectionMeasurement using dc-ac conversionVoltage-current phase angleEngineeringSwitchgear

The invention provides a 10KV switchgear nuclear phase vehicle, and belongs to the field of insulating protective equipment. The 10KV switchgear nuclear phase vehicle comprises a chassis, wherein a fixing clamping piece is arranged on the side surface of the chassis, and a hole is formed in the side surface of the chassis; a screw is arranged in the hole through a bearing, and a nuclear phase vehicle is arranged on the chassis through roller wheels; a screw hole is formed in the side surface of the nuclear phase vehicle, and the screw penetrates through the screw hole and is mutually matched with the screw hole; a support is arranged on the nuclear phase vehicle, and an insulating protective plate is arranged on the support; contact holes are formed in the insulating protective plate, and propulsion supports are also arranged at the two sides of the nuclear phase vehicle. A contact baffle can be opened very conveniently without risks.

Owner:HUANTAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

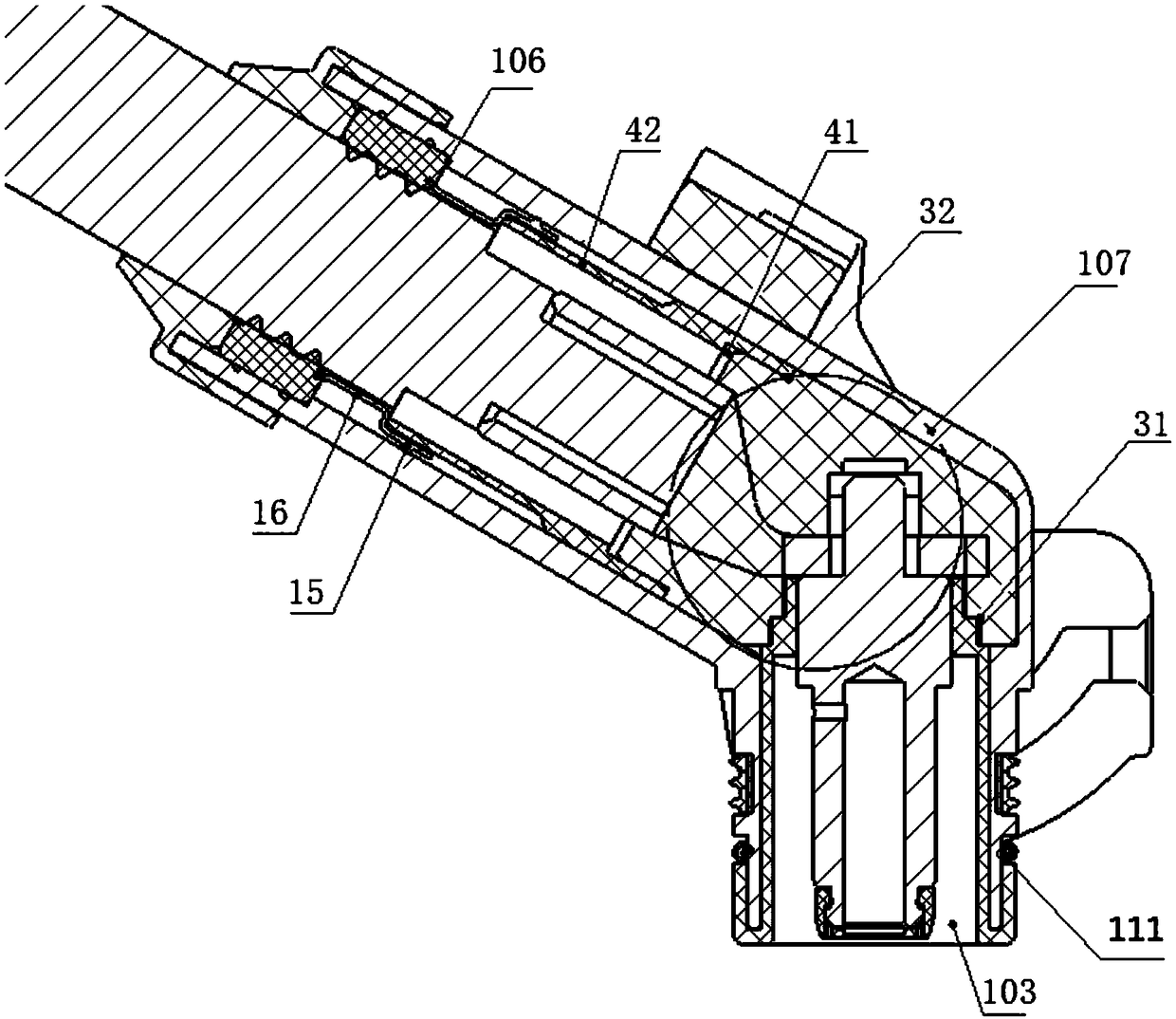

An integral 120-degree outlet electrical connector plug

ActiveCN108988001AApplicable usage requirementsImprove shielding effectCoupling device detailsTwo-part coupling devicesState of artEngineering

The invention discloses an integral 120-degree outlet electrical connector plug, belonging to the technical field of the electrical connector, which comprises a plug housing, a plug front mounting plate, a sealing ring, a pin assembly, a signal short connector and a plug tail cover. The plug shell comprises a front end of the plug shell and a rear end of the plug shell connected with the front endof the plug shell, wherein the pin assembly is arranged in a receiving cavity of the pin assembly, and a signal short connector is arranged in the receiving cavity of the short connector. A shield contact spring mounting groove is arranged at the front end of the plug housing, and a shield contact spring is arranged in the shield contact spring mounting groove; The inside of the rear end of the plug housing is provided with an adapter accommodation cavity at a position communicating with the accommodation cavity of the plug front mounting plate. The invention solves the problems of large volume, low assembling efficiency, low shielding effectiveness and high cost of the existing 120-degree electrical connector plug by adopting the integral 120-degree outlet connector plug. Compared with the prior art, the invention has the advantages of small volume, high assembling efficiency, high shielding effectiveness and low cost.

Owner:SICHUAN YONGGUI SCI & TECH CO LTD

Automatic short-circuit air plug

ActiveCN108023199AEnsure security and stabilityReduce labor intensityCoupling contact membersTwo-part coupling devicesEngineeringUltimate tensile strength

The invention discloses an automatic short-circuit air plug, and relates to the technical field of a power distribution network. The automatic short-circuit air plug comprises a first insertion core and a second insertion core, wherein at least two rows of first insertion pieces are arranged on the first insertion core, at least two rows of second insertion pieces are arranged on the second insertion core, the automatic short-circuit air plug has a combination state and a split state, the first insertion core is provided with an automatic short-circuit mechanism, the second insertion core is provided with a cutoff mechanism, in the split state, at least one pair of first insertion pieces in adjacent two rows are short-connected by the automatic short-circuit mechanism, in the combination state, the contact of the automatic short-circuit mechanism and the first insertion pieces is cut off by the cutoff mechanism, and the first insertion pieces and the second insertion pieces are conducted with each other. The automatic short-circuit air plug has an automatic short-circuit function, the labor intensity is reduced, and the safety coefficient and the working efficiency of site installation and maintenance are substantially improved.

Owner:杭州中电天恒电力科技有限公司

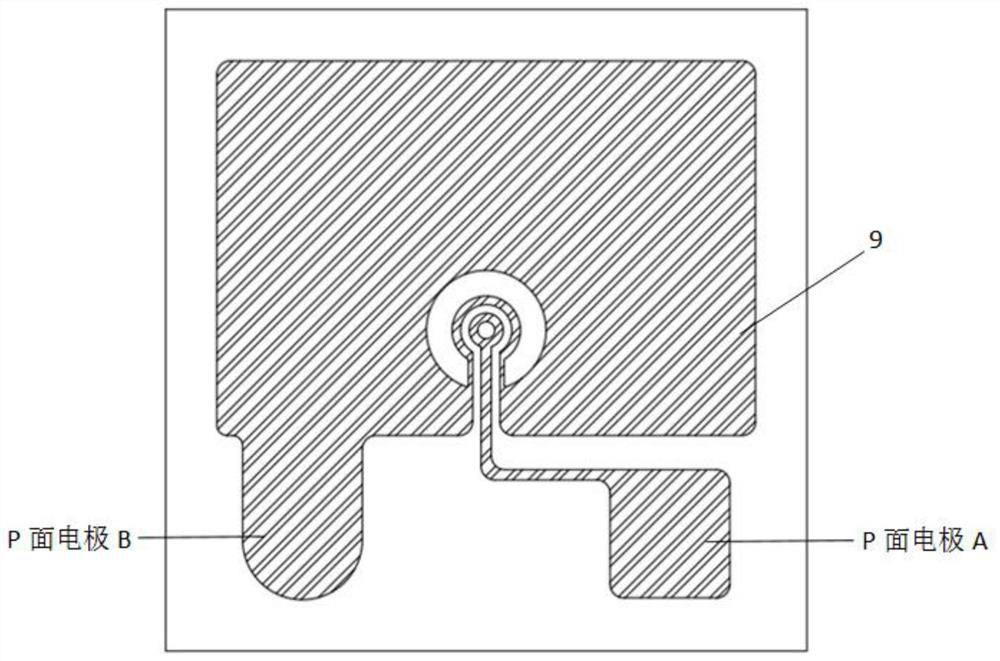

Light-emitting diode with variable pattern and preparation method thereof

ActiveCN112750922AIncrease profitVariableSighting devicesSemiconductor devicesLight-emitting diodeTelescope

The invention discloses a light-emitting diode with a variable pattern and a preparation method thereof. The diode comprises an epitaxial wafer, wherein an ITO film is evaporated on the upper surface of the epitaxial wafer, the ITO film is provided with a plurality of light-emitting areas and etching areas, each light-emitting area is correspondingly provided with a P-surface electrode, the adjacent P-surface electrodes are insulated and separated, an insulating layer is deposited on the surface of each etching area, and an N-face electrode is evaporated on the end face of the side, away from the ITO film, of the epitaxial wafer. The method is simple in structure and reasonable in step design, the prepared light-emitting diode can be used independently, does not need to work in cooperation with a reticle and can emit needed patterns, and the advantages of simple structure and low power consumption are guaranteed while the utilization rate of a light source is improved; and meanwhile, the luminous pattern of the diode prepared by using the technical scheme has variability, and can be changed according to a distance between a reflection sighting telescope and a target, and the practicability of the diode is relatively high.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Protective oral cavity opening device for oral cavity digital repair

ActiveCN109394158ARotation Movement GuaranteeEasy to rotate and moveEndoscopesSomatoscopeEngineeringProtection layer

The invention relates to a protective oral cavity opening device for oral cavity digital repair. The protective oral cavity opening device includes a bottom cushion and support blocks, a cushion blockis arranged at the rear end of the bottom of the bottom cushion, a tooth cavity is formed in the front end of the bottom of the bottom cushion, a protection layer is arranged on the inner wall of thetooth cavity, the support blocks are arranged at the upper ends of the left and right sides of the bottom cushion, sliding rails are installed inside the support blocks, and pulleys are arranged on the inner walls of the sliding rails. The protective oral cavity opening device for oral cavity digital repair has the advantages that fixing cushions, a top cushion, springs and welding blocks are arranged, the fixing cushions are movably connected with the top cushion and are fixedly connected with the bottom cushion through the support blocks, so that the top cushion is supported through the effect of an expanding device, and it is convenient to adjust the support height; through the effect of the springs, the top cushion has elasticity and can elastically deform to a certain degree, therefore, it is convenient to conduct restoration when a patient occludes, and it is convenient for the patient to take occlusion exercise, so that the protective oral cavity opening device is convenient touse.

Owner:上海东慧口腔医院有限公司

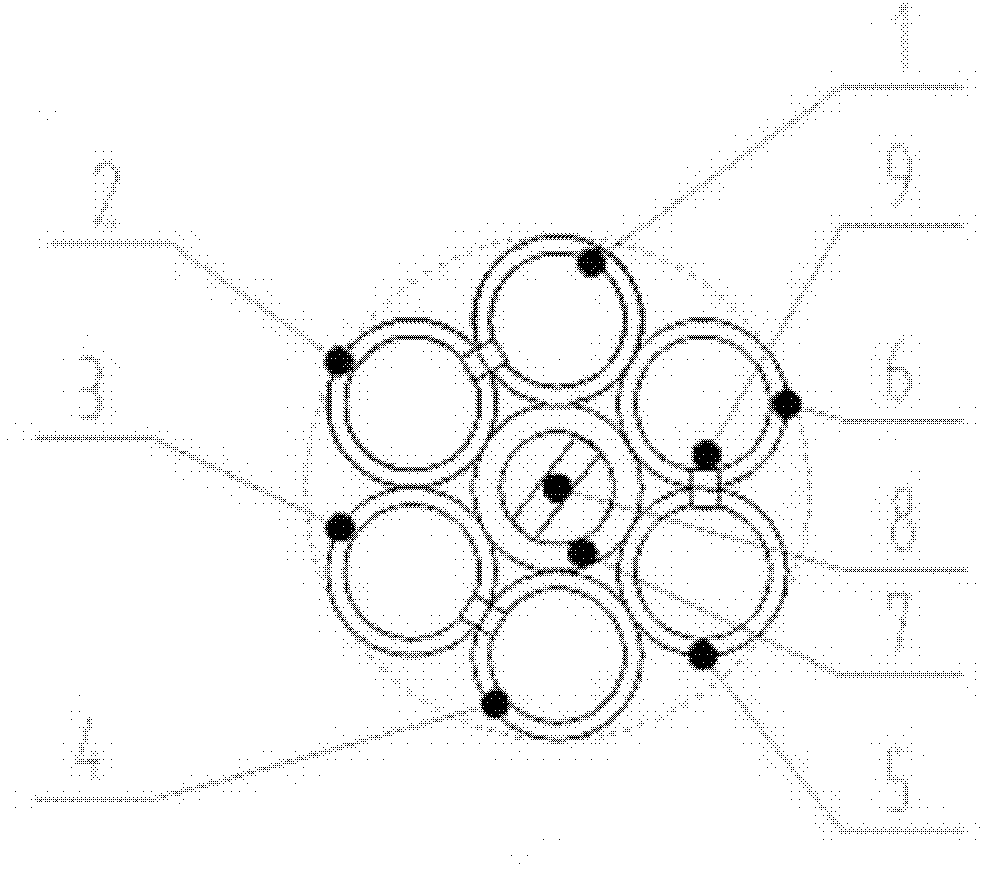

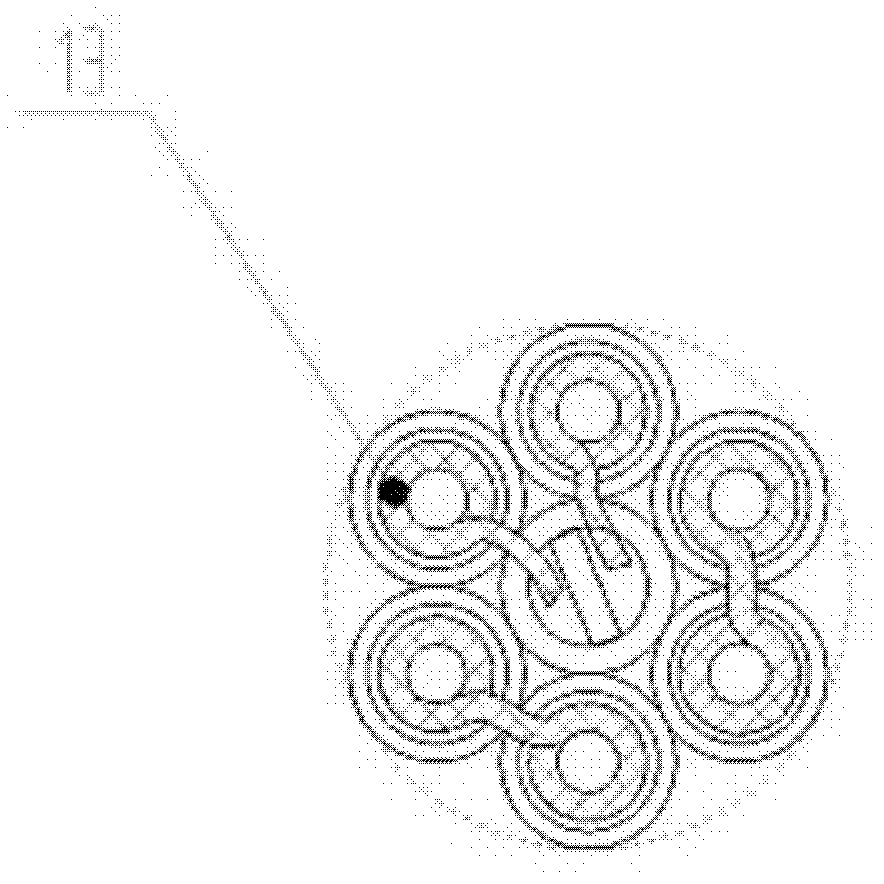

Integrated heating core for built-in porous heater and manufacturing method thereof

InactiveCN103002602AImprove heat exchange efficiencyGood air permeabilityCosmonautic propulsion system apparatusHeater elementsTransition lineBoron nitride

The invention discloses an integrated heating core for a built-in porous heater and a manufacturing method thereof. The integrated heating core comprises a heating body, a heating body frame and a transition line, wherein the heating body is helically shaped and made of bar-type meshed porous nichrome alloy or bar-type meshed porous nickel-chromium alloy, the heating body frame is formed by closely arranging seven porous boron nitride tubes, the close arrangement of the seven porous boron nitride tubes include six surrounding porous boron nitride tubes and one central porous boron nitride tube, a separation plate is arranged in the central porous boron nitride tube, notches are formed at two ends of the surrounding porous boron nitride tubes, the heating body penetrates through the surrounding porous boron nitride tubes back and forth sequentially via the notches, and two ends of the heating body are leaded out from two sides of the separation plate of the central boron nitride tube after being welded with the transition line. The integrated heating core is the basis for manufacturing the built-in heater, and is high in resistance and heat exchange rate, small in size, stable in structure, and good in air permeability and insulation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Flame-retardant carbon crystal heating plate and preparation method thereof

PendingCN106455153AImprove the effect of hot pressingImprove securitySynthetic resin layered productsLaminationGraphite carbonHeat resistance

The invention discloses a flame-retardant carbon crystal heating plate comprising: 1) first fixing one end of a copper strip to the front face of a first resin layer, with the other end extending to the outside of the first resin layer; 2) then applying graphite carbon paste to the front side of the first resin layer to form a graphite layer, and coating one end of the copper strip with the graphite carbon paste; 3) hot pressing a second resin layer onto the graphite layer to obtain a sandwich panel; and 4) hot pressing mica paper on both sides of the sandwich panel, and obtaining a flame-retardant carbon crystal heating plate after natural cooling. The flame-retardant carbon crystal heating plate is capable of long-time uniform heating, excellent resistance to high pressure and heat, and safe usage.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com