Electromagnetic induction selective laser melting powder bed on-line heating system and method

A technology of laser selective melting and electromagnetic induction coil, applied in the field of additive manufacturing, which can solve the problems of limited heating temperature, limited temperature in the forming height direction, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

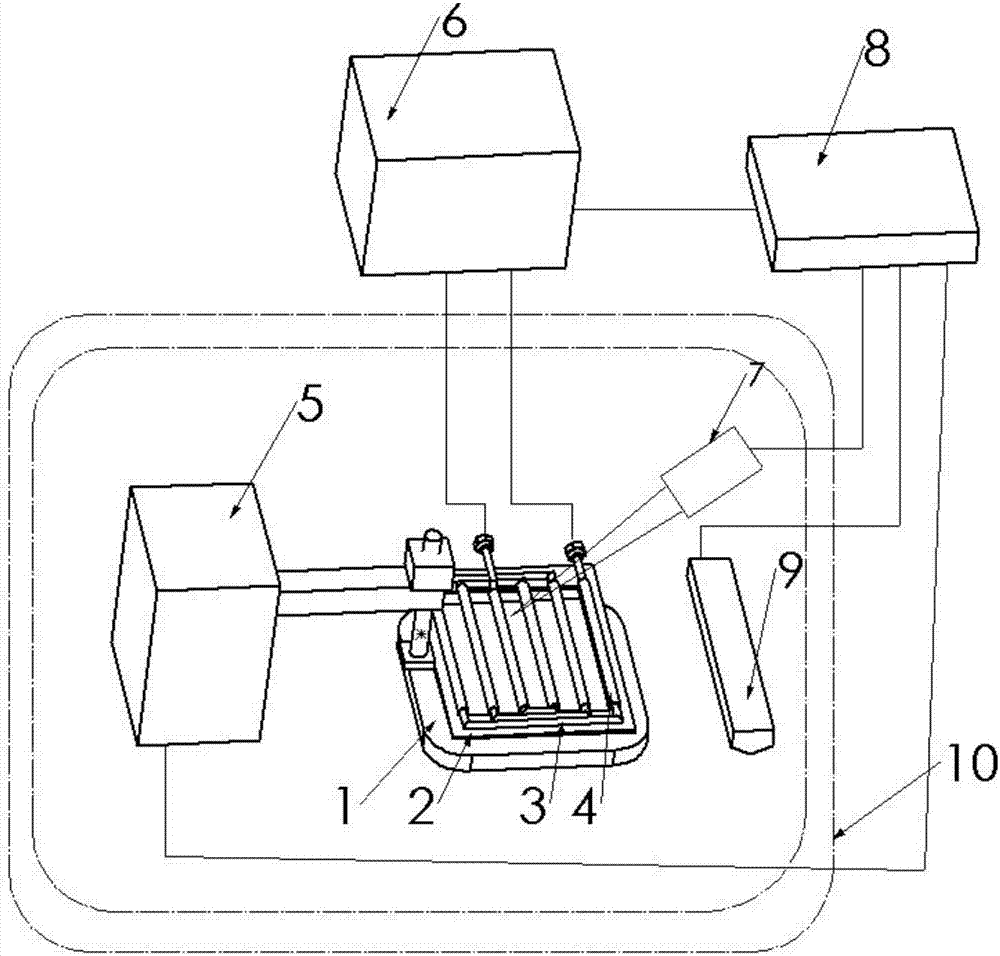

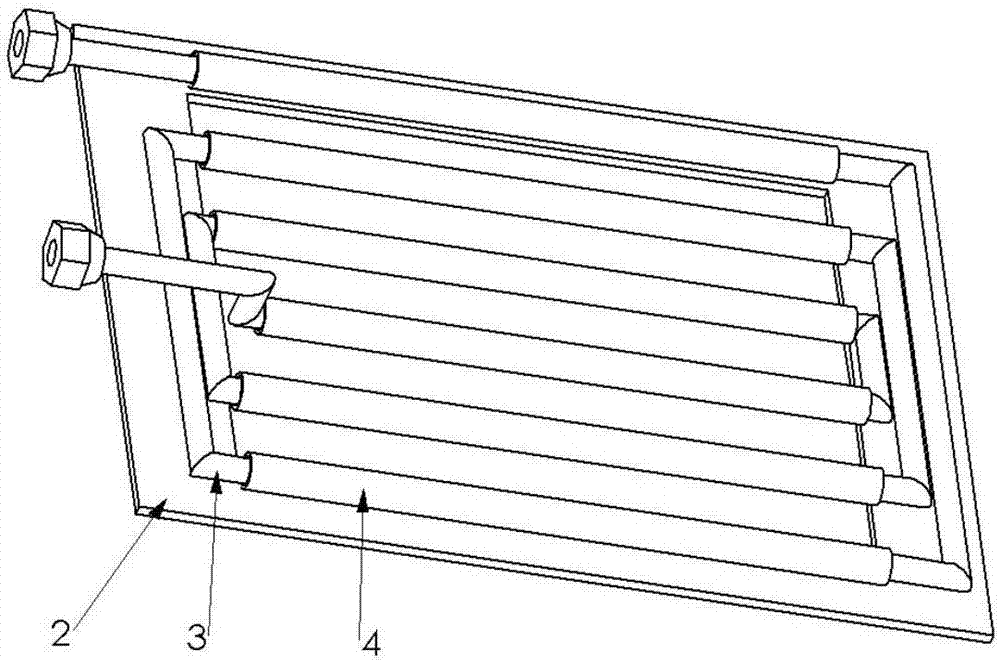

[0043] Such as figure 1As shown, an electromagnetic induction laser selective melting powder bed online heating system includes a powder bed 1 in a laser selective melting forming chamber 10, a metal electromagnetic induction coil 3 is arranged above the powder bed 1, a metal electromagnetic induction coil 3 and an intermediate frequency or high frequency The frequency heating power supply 6 is connected, the intermediate frequency or high frequency heating power supply 6 is connected to the central controller 8 through the control line, the metal electromagnetic induction coil 3 is fixed on the non-metallic high-temperature resistant support 2, and the non-metallic high-temperature resistant support 2 is connected to the three-dimensional mobile support 5 Above, the three-dimensional mobile support 5 is fixed in the laser selective melting forming room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com