Automatic putting method of temperature and pressure reducer

A desuperheater and pressure reducer, automatic input technology, applied in the control of machine/engine, engine components, superheat temperature, etc., can solve the problem that the desuperheater and pressure reducer cannot be put into use in time, so as to avoid boiler accidents and save energy time, ensuring the effect of continuous heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

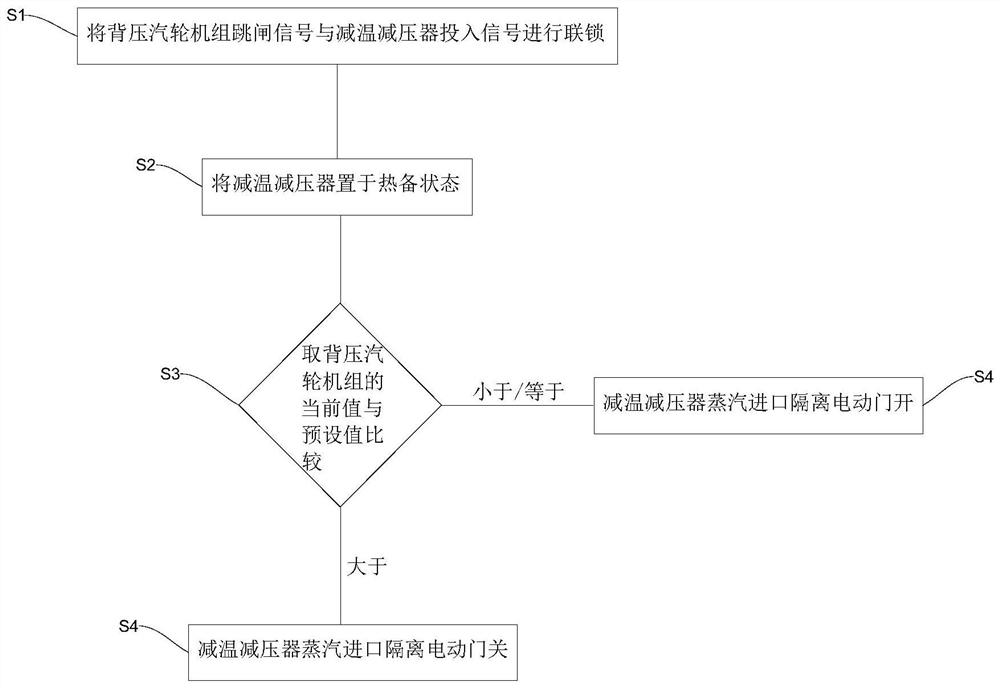

[0027] A method for automatically putting in a desuperheater and pressure reducer, comprising the following steps:

[0028] S1. Interlock the trip signal of the back pressure steam turbine unit with the input signal of the temperature reducer;

[0029] S2. Put the temperature and pressure reducer in a hot standby state;

[0030] S3. Take the current value of the back pressure steam turbine unit and compare it with the preset value 0.8;

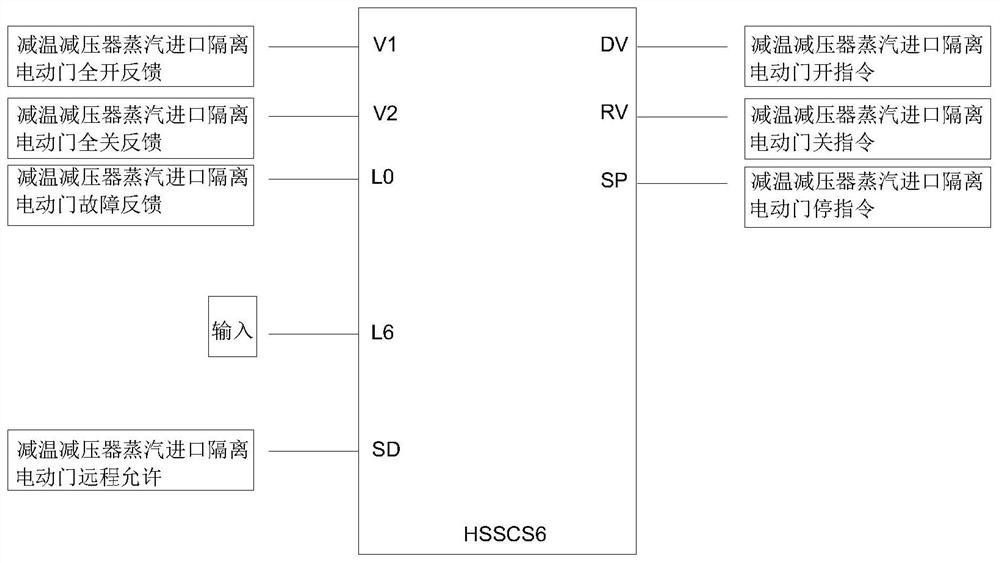

[0031] S4. If the current value of the back pressure steam turbine unit is less than or equal to the preset value 0.8, the steam inlet isolation electric door of the desuperheater and pressure reducer is opened; if the current value of the back pressure steam turbine unit is greater than the preset value 0.8, the temperature and pressure reduction The steam inlet of the appliance is isolated and the electric door is closed.

[0032] Step S3 includes the following steps:

[0033] S31. Take the remote pressure value of the safety oil pipeline...

Embodiment 2

[0047] Step S3. Take the remote pressure value of the safety oil pipeline of the back pressure steam turbine unit, the established value of the safety oil pressure of the back pressure steam turbine unit and compare it with the preset value 1. When the remote pressure value of the safety oil pipeline of the back pressure steam turbine unit and the safety oil pressure establishment value of the back pressure steam turbine unit are both less than or equal to the preset value 1, the steam inlet isolation electric door of the desuperheater and pressure reducer is opened; when the back pressure steam turbine unit When the remote pressure value of the safety oil pipeline and the established value of the safety oil pressure of the back pressure steam turbine unit are both greater than the preset value 1, the steam inlet of the desuperheater is isolated and the electric door is closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com