Complementary solid electric heat storage unit

An electric heat storage and complementary technology, applied in central heating, can solve the problems of not meeting the requirements of one standby and one use, large temperature difference between the hot and cold ends of the heat storage body, and unsaturated heat storage of the heat storage body, so as to achieve sufficient maintenance The effect of time, small temperature difference between cold and hot ends, uniform and saturated heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

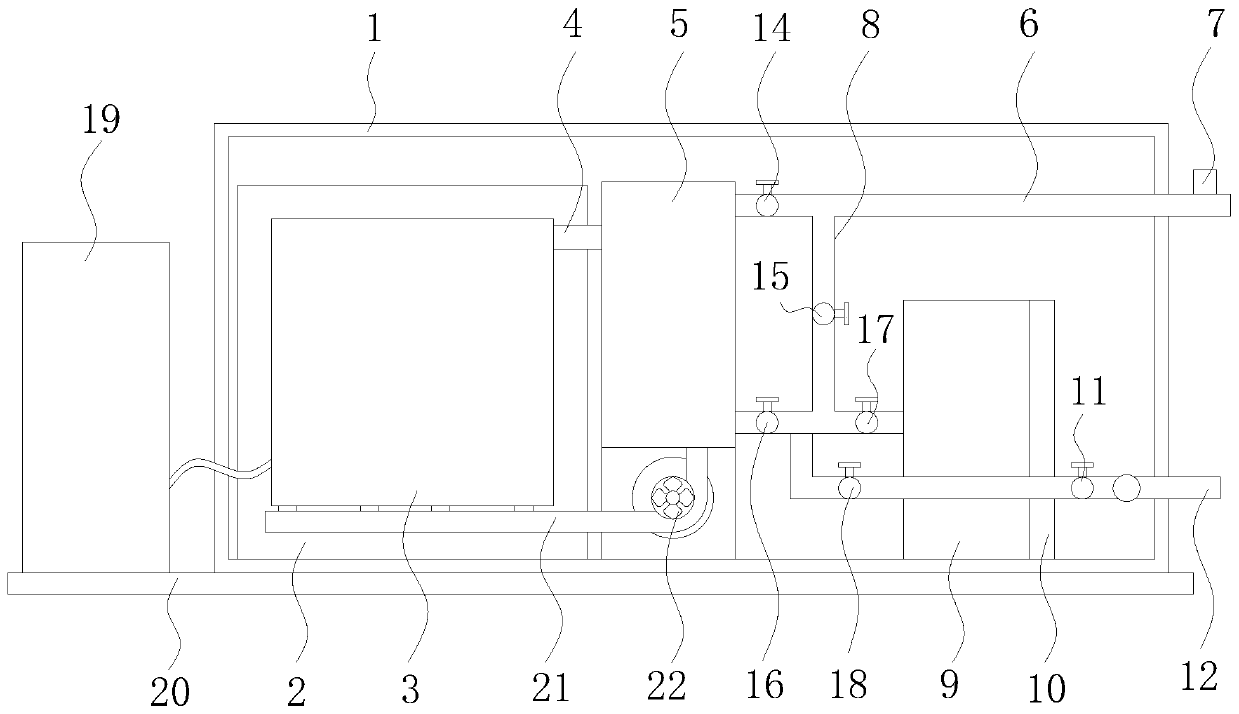

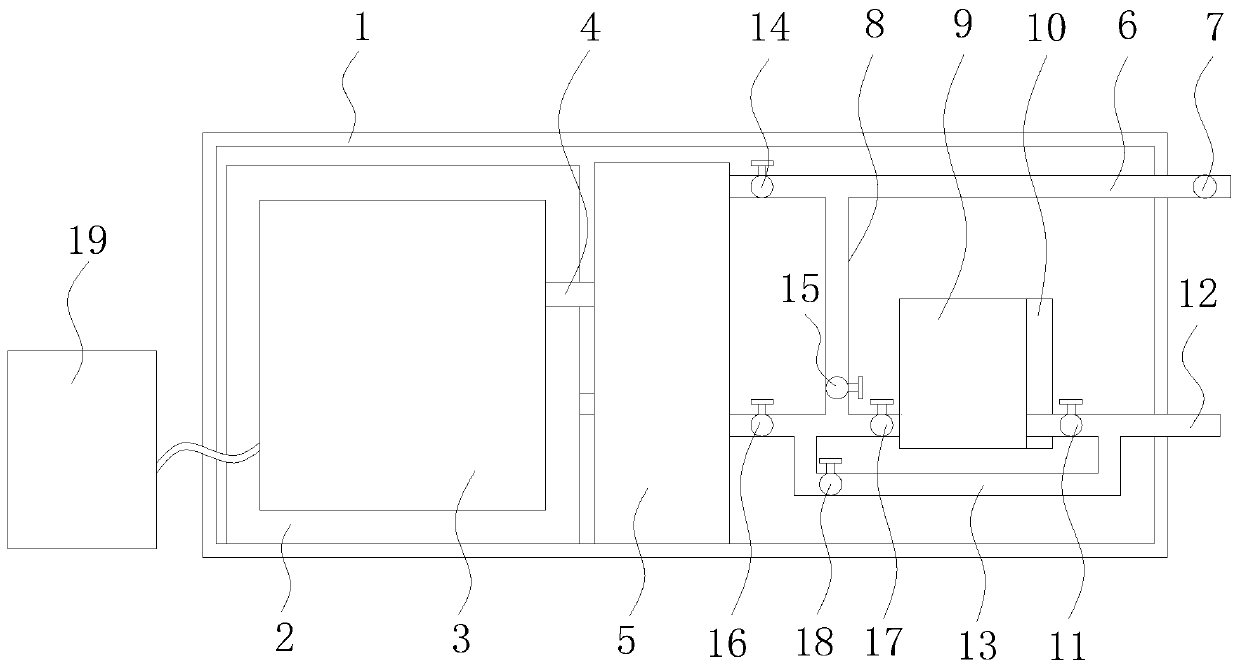

[0028] A complementary solid electric heat storage unit, comprising an outer casing 1 and a solid electric heat storage boiler 3 arranged in the inner cavity of the outer casing 1, the outer side of the solid electric heat storage boiler 3 is covered with an insulation layer 2, and the solid electric heat storage boiler 3 The air inlet end of the heat storage boiler 3 is connected to the air outlet end of the heat exchanger 5 through the upper air duct 4, the heat exchanger 5 is arranged in the inner cavity of the outer casing 1, and the air inlet end of the heat exchanger 5 passes through the lower air duct 21 Connect the air outlet end of the solid electric thermal storage boiler 3, and the fan 22 is installed on the lower air duct 21;

[0029] In this example, if Figure 1-2 As shown, the water inlet end and the water outlet end of the heat exchanger 5 are respectively equipped with a water inlet pipe 12 and an outlet pipe 6, and both the water inlet pipe 12 and the water o...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is that, as figure 1 and 2As shown, the lower parallel connection pipe 13 in a U-shaped structure is installed through the water inlet pipe 12, and the two connection ports of the lower parallel connection pipe 13 are located outside the water inlet end and the water outlet end of the direct heating electric boiler 9 respectively. A lower parallel regulating valve 18 is installed on the lower parallel connecting pipe 13 to ensure that the water inlet pipe 12 can be adjusted by the lower parallel connecting pipe 13 and the lower parallel regulating valve 18 when the direct-heating electric boiler 9 is overhauled, and the incoming water source crosses the direct The heat-type electric boiler 9 enters the heat exchanger 5 and realizes heating water supply and heating through the solid electric heat storage boiler 3, without stopping the heating supply for maintenance, and has sufficient maintenance time.

[0039] Ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com