High-precision temperature and pressure sensor

A technology of temperature, pressure and sensors, which is applied in the field of sensors, can solve the problems of temperature difference between the actual temperature, inaccurate measurement results, and low production efficiency, and achieve the effect of less pressure loss, good measurement effect and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further improved in conjunction with the accompanying drawings and embodiments below.

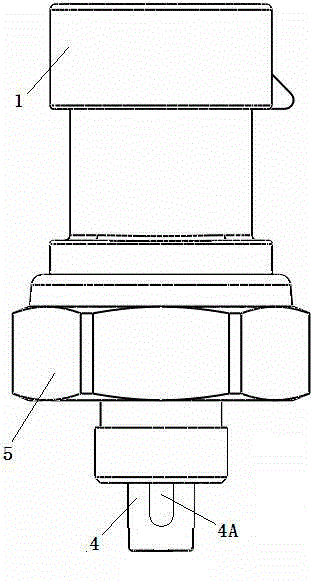

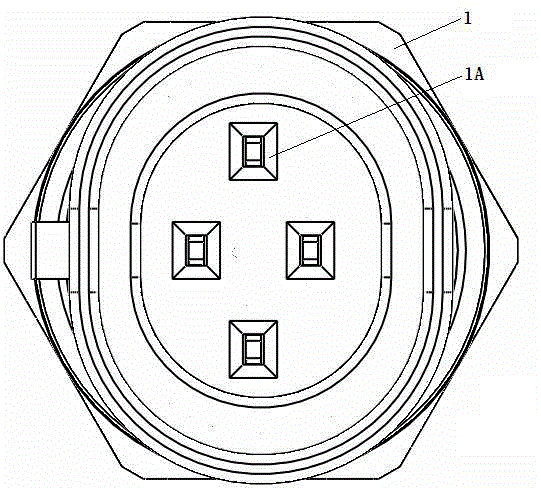

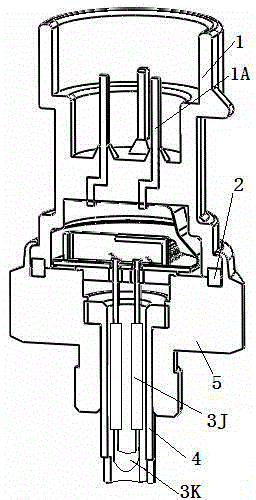

[0042] Such as Figure 1 to Figure 4 As shown, a high-precision temperature and pressure sensor includes a terminal button 1 with a pin 1A, a TO assembly 3, and a housing 5. The terminal button 1 is sealed with the housing 5 and is provided with interconnected capacitors on both sides of the sealing surface. The end of the shell 5 away from the end button 1 is provided with a through hole communicating with the cavity, the TO assembly 3 is located in the cavity, and the TO assembly 3 includes a TO plate 3I that seals the opening of the cavity on the shell 5, and the end button The PCB board 3H soldered to pin 1A on 1 (in this embodiment, the PCB board 3H is a flexible circuit board) and thermistor 3K, the PCB board 3H is arranged on the top surface of the TO board 3I, and the TO board 3I is provided with a thermistor connecting rod 3B (there are two the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com