Method for enhancing photocatalysis performance of ferroelectric material through regulation and control of spontaneous polarization

A ferroelectric material, a technology of spontaneous polarization, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as lack of control means, and achieve photocatalysis The effect of performance improvement and photocatalytic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

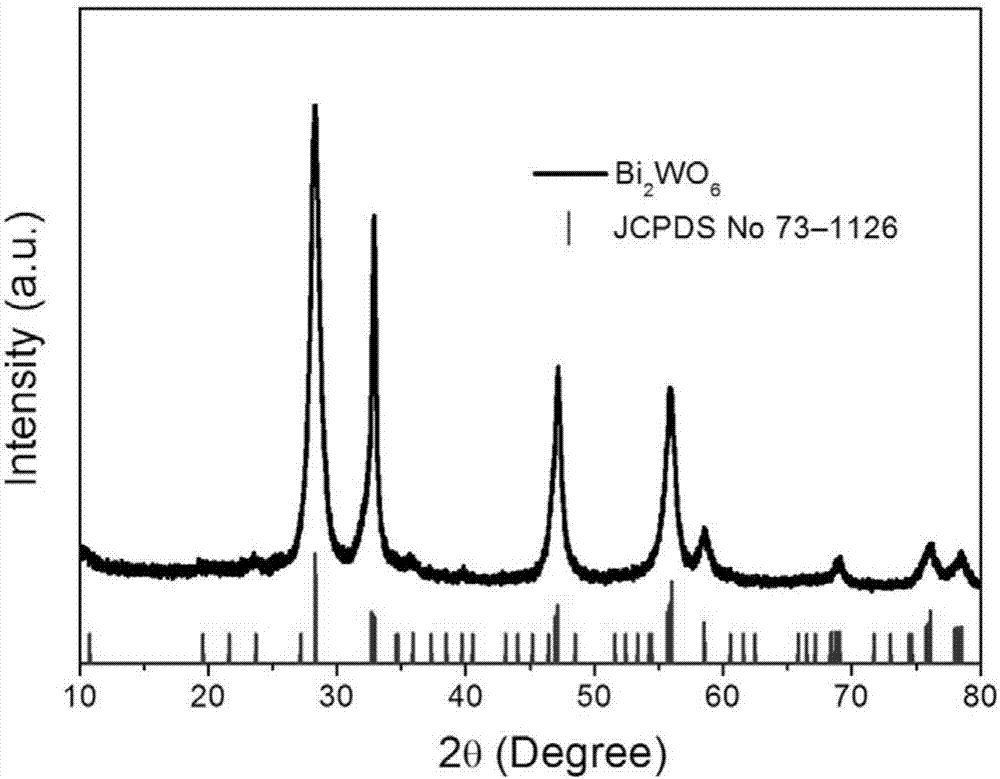

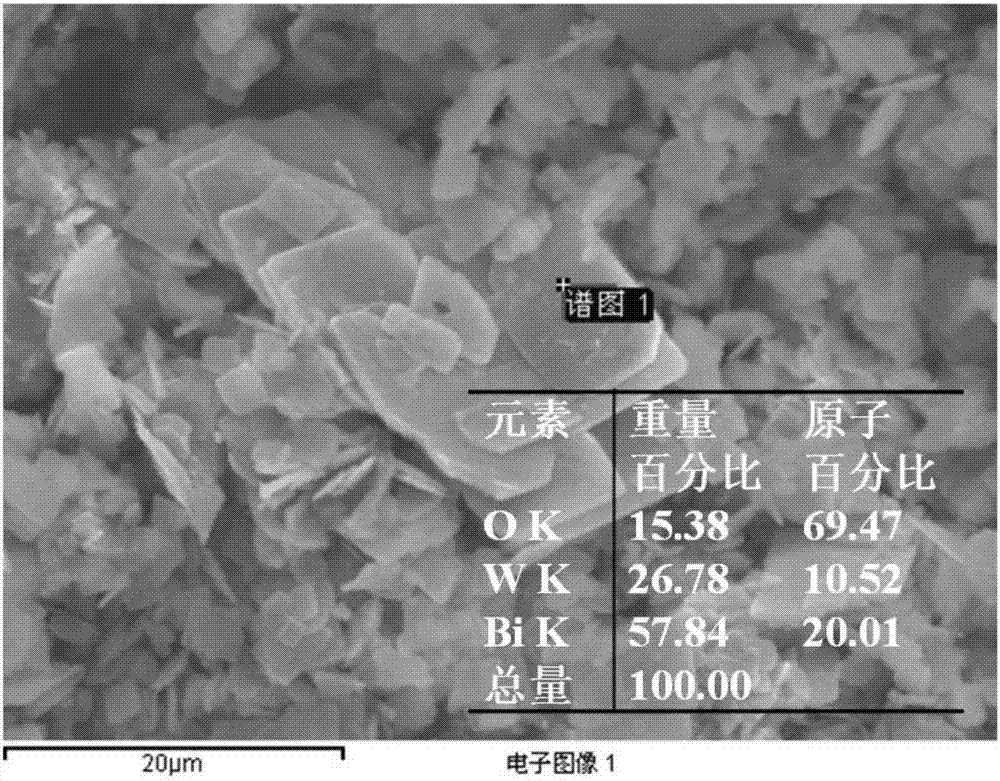

[0029] Bismuth tungstate (Bi 2 WO 6 ) to enhance the photocatalytic performance, specifically:

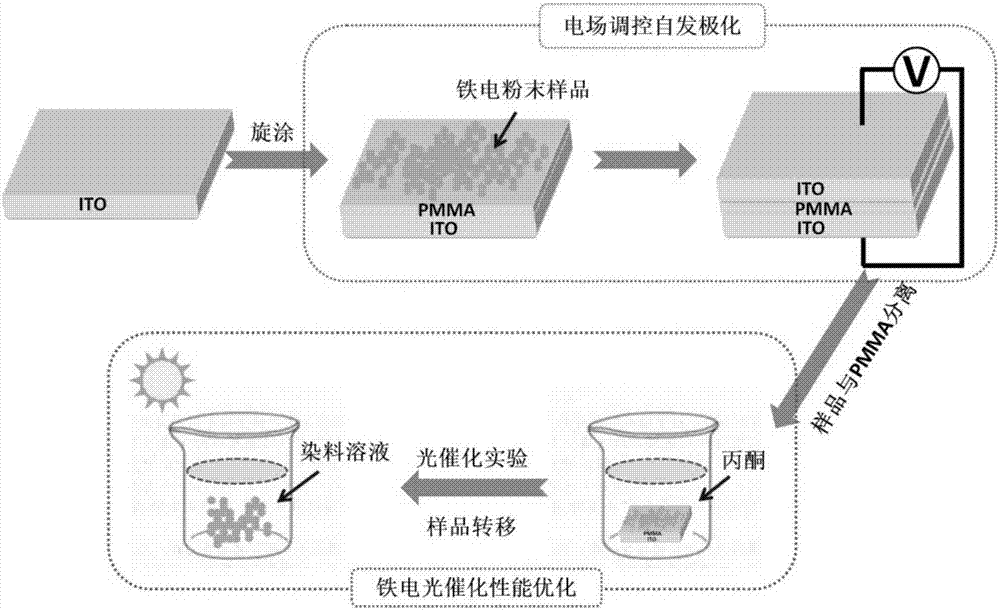

[0030] 1) Dissolving the soluble polymer material polymethyl methacrylate (PMMA) in ethyl acetate, the addition ratio is 0.5g PMMA dissolved in 10mL ethyl acetate solvent, stirring evenly on a magnetic stirrer to prepare a clear solution;

[0031] 2) Add 1g Bi directly to the above mixed solution 2 WO 6 Powder, mix the mixture evenly under continuous stirring;

[0032] 3) Take a small amount of the above mixed solution, and evenly drop it on the cleaned ITO conductive glass substrate, or spin-coat it on the conductive glass substrate through a coater to prepare an organic film with a thickness of less than 1mm;

[0033] 4) Transfer the above insulating film to an oven at 60°C for drying for more than 15 minutes, so that the ethyl acetate is fully volatilized, and a flat insulating film is prepared;

[0034] 5) Prepare another piece of the same material, whose size is slightly ...

Embodiment 2

[0039] Bismuth ferrite (BiFeO) controlled by an external electric field 3 ) to enhance the photocatalytic performance, specifically:

[0040] 1) Dissolving the soluble polymer material polymethyl methacrylate (PMMA) in ethyl acetate, the addition ratio is 0.5g PMMA dissolved in 10mL ethyl acetate solvent, stirring evenly on a magnetic stirrer to prepare a clear solution;

[0041] 2) Add 1g BiFeO directly to the above mixed solution 3 Powder, mix the mixture evenly under continuous stirring;

[0042] 3) Take a small amount of the above mixed solution, and evenly drop it on the cleaned ITO conductive glass substrate, or spin-coat it on the conductive glass substrate through a coater to prepare an organic film with a thickness of less than 1mm;

[0043] 4) Transfer the above insulating film to an oven at 60°C for drying for more than 15 minutes, so that the ethyl acetate is fully volatilized, and a flat insulating film is prepared;

[0044] 5) Prepare another piece of the same...

Embodiment 3

[0048] Tuning barium titanate (BaTiO) by applying an electric field 3 ) to enhance the photocatalytic performance, specifically:

[0049] 1) Dissolving the soluble polymer material polymethyl methacrylate (PMMA) in ethyl acetate, the addition ratio is 0.5g PMMA dissolved in 10mL ethyl acetate solvent, stirring evenly on a magnetic stirrer to prepare a clear solution;

[0050] 2) Add 1g BaTiO directly to the above mixed solution 3 Powder, mix the mixture evenly under continuous stirring;

[0051] 3) Take a small amount of the above mixed solution, and evenly drop it on the cleaned ITO conductive glass substrate, or spin-coat it on the conductive glass substrate through a coater to prepare an organic film with a thickness of less than 1mm;

[0052] 4) Transfer the above insulating film to an oven at 60°C for drying for more than 15 minutes, so that the ethyl acetate is fully volatilized, and a flat insulating film is prepared;

[0053] 5) Prepare another piece of the same mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com